Project: Redevelopment of Didcot Parkway Station.

Objective: Provide sustainable surface water management which could be installed quickly and with minimal disruption.

Solution: ACO StormBrixx attenuation system and ACO Q-Brake Vortex Flow control devices.

Results: A sustainable surface water management system with space saving benefits which helped contractors successfully complete the challenging groundworks phase of this development.

Due for completion in Spring 2014, the £6.7m redevelopment of Didcot Parkway Station in Oxfordshire has just seen the successful completion of its groundworks - a challenging phase of the project in which ACO’s space-saving stormwater attenuation tank, StormBrixx, has played an important role.

The infrastructure project is centred on resolving the station’s poor layout, traffic congestion and its vulnerability to flooding. When complete, it will provide an attractive and efficient interchange for public and private transport, ensuring it has the capacity to meet future travel demand as the number of people living and working in the

area increases.

Tackling the flooding issue, main contractor Balfour Beatty has installed a sustainable surface water management scheme (developed by Jacobs Engineering Group) that utilises space beneath two of the station’s three new car parks to accommodate attenuation tanks with sufficient capacity to hold and safely discharge run-off from across the redesigned pedestrian piazza and forecourt.

“In order to achieve the volume required, we have had to excavate virtually the entire deck area of the two car parks. Restricted by a major trunk road on one side and the rail track embankment on the other, it left very little free space for the groundworkers and tank installers to store equipment” says Balfour Beatty Site Agent, Tony Mills. “Tight installation schedules added to the challenge. To avoid delays we needed to have all the tank components on-site to allow the build team to work unhindered once the excavation stage was complete.

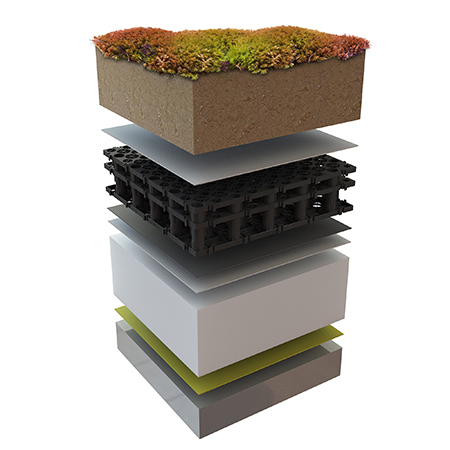

Key to Balfour Beatty’s decision to use ACO StormBrixx is its unique modular design which allows all the tank components to be stacked, transported and stored in just 25% of the space required by conventional crate-based systems. Less cumbersome and easier to handle, StormBrixx produces a stronger more stable structure that can be configured to any size or location, overcoming the construction limitations and drawbacks suffered by traditional tanks.

“Using StormBrixx’s not only were we able to hold sufficient stock within the tight space to keep the laying team adequately supplied, but we were also able to reduce transportation costs as both tanks could be loaded onto a single truck. This has the added benefit of significantly lowering the whole logistics operation’s carbon emissions.”

The two tanks are inter-connected with a single discharge (limited to a maximum 10 litres/second) to an adjacent watercourse. The upstream ‘offline’ tank has a volume of 297 m3 and only fills if run-off flowrates from its catchment exceed 4 litres/second. The downstream ‘online’ tank attenuates both the run-off from the offline catchment as well as from its own.

Run-off discharge rates from both catchments are controlled using two ACO Q-Brake Vortex flow control units. The discharge from the online tank first passes through an oil separator before being released into the watercourse.

As the tanks are set up to attenuate stormwater, each is wrapped in a two part membrane that prevents any infiltration into the surrounding sub-soil and eliminates any silt penetrating the tank walls. First a welded geomembrane liner system sits immediately adjacent to the tank walls; this is then encased in a protection fleece which safeguards the integrity of the overall structure.

View Case Study: ACO StormBrixx Didcot Parkway Station PDF