It can be agreed that when it comes to countries where football is more than a game, Brazil is one of them.

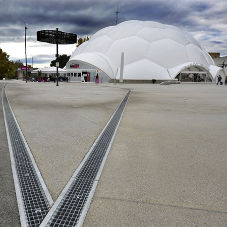

From now on Brazilian football will have a new stadium in the city of Belo Horizonte, in the state of Minas Gerais: the Arena MRV, the new stadium being built for Clube Atlético Mineiro.

This macro-project, which has a built surface area of 185,655.19 m², was designed by the architectural studio Farkasvölgyi Arquitetura.

This tremendous structure will hold 47,000 seats, making it one of the country's ten biggest stadiums in terms of capacity.

But now let's turn the attention to another form of capacity, the one ULMA knows about: rainwater drainage capacity.

Technical advice

When a macro-project like this is initiated, execution costs and times play a key role.

This is where ULMA can offer their expertise; in guaranteeing that the proposed channel systems are optimal in terms of both drainage capacity and cost.

ULMA has a secret: thanks to a multi-platform software they have developed to perform hydraulic studies, they know beforehand which channel model is the most suited to each project.

For the Arena MRV, there were early plans to use channels manufactured on-site with a total width of 450 mm and an initial height of 200 mm.

However, after performing a hydraulic study, ULMA determined that laying out channels in the form of a cascaded slope would be the best option.

Cascaded channels

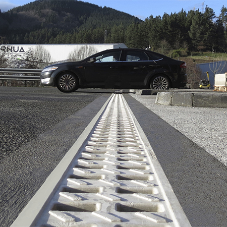

The installation of cascaded channels is a combination of straight channels at different heights that are joined using connecting shims.

This is a simple (and economic) option for areas where slopes must be used, as was the case here.

For the Arena MRV, ULMA used U100 channels with a height that varied between 130 mm and 230 mm, in response to the same flow as the initial design.

It is a lighter (and more economical) choice, but has the same drainage capacity as the option initially proposed.

How is that possible? Thanks to polymer concrete.

Polymer concrete and cost optimisation

The surface of their polymer concrete channels is so smooth that they allow more water to be drained away in less time. This and other properties make it possible to manufacture lighter channels with smaller cross-sections.

That way, they can reduce costs, turning lightness into economics. Because installation is simpler and faster.

Furthermore, the grating used has routers that help to collect water, an anti-slip surface, and a distinctive aesthetic finish. In addition, all grating components have their own fixing system, guaranteeing improved resistance and safety.

Thanks to ULMA's expertise and the technical properties of the material, the customer opted for their drainage solutions, saving on costs without having to forego drainage capacity.

If you want to ensure the proposed channel systems are optimal in terms of both drainage capacity and cost, contact ULMA.

Cascaded drainage solution for the Arena MRV

| T | (+44) 0754 2982 022 |

|---|---|

| 0793 221 5849 Tech Dept. | |

| E | mikelgarcia@ulmaarchitectural.com |

| W | Visit ULMA Architectural Solutions's website |

| Unit 20B Access 18, Avonmouth, Bristol, BS11 8HT |