Recent history indicates that when serious flood damage occurs, occupiers have to leave their homes for considerable amounts of time. However, Delta Membrane Systems offers a package of measures that could greatly reduce the time spent on remediating this problem.

Delta has recently come across such a case in Hessle, near Hull. As a result of last year’s flooding a family watched water levels rise to first-floor window sill height at their property.

The heart was ripped out of their home as the squatters moved in, in the form of dryers and dehumidifiers. Day after day, week after week, these units chattered away, much of it unnecessary. And, a full year after the event, the family is still not back in their home.

Delta Membranes has pioneered a method of reinstatement that dramatically reduces the time families must endure with the disruption to their lives by eliminating the need for traditional drying with resultant cost saving to their insurers.

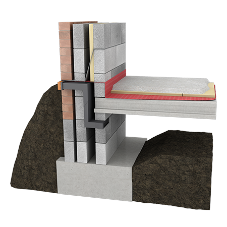

This prolonged drying out period – a fundamental prerequisite for the adhesion of new internal finishes – can be regarded as an irrelevance if the said finishes can be installed onto a dry substrate which provides physical separation from the damp structure.

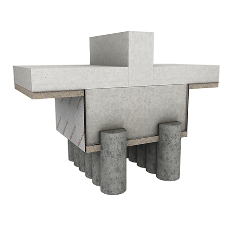

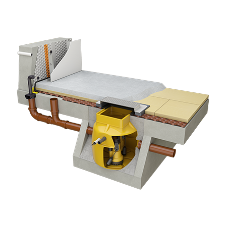

Delta’s 20 years experience in the use of cavity membranes to create a waterproofed box within existing damp basements and cellars is now being employed to remediate flood damaged properties that suffer from dampness entrapped in the structure.

The PT cavity membrane can be fixed to a damp wall, and be dot and dabbed, and skimmed, in a fraction of the drying time demanded by traditional methods of remediation. The HDPE cavity membrane ensures air can circulate behind it, picking up residual moisture from the structure over the coming months without affecting the new finishes.

The same result can be achieved on the floors. Delta’s FM cavity membrane can be loose laid over wet concrete floors and have a new floating floor system installed directly onto it. The 3mm air space created by the membrane again provides the physical separation for the new finishes and allows slow drying without significantly reducing head room.

As a result, the house can be returned to its rightful owners more swiftly with less disruption to the family and at a reduced accommodation cost to the insurers.

The enabling works consisted of removing all plaster finishes up to ground floor ceiling height, stripping out the timber floor and replacing it with concrete.

Once completed, the installation of the membranes (65m2 of walls and 40m2 of floor) was completed in just 45 man hours or one working week. Immediately, plasterers got to work and replastered and skimmed again within a week.

With this method, those who have suffered enough through the misery of flooding can quickly look forward to a warm welcome home.

View Flood Resilience and Recoverability Product Entry

227.png)