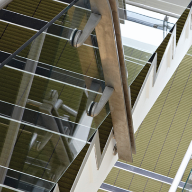

The clean, contemporary lines of glass and stainless steel balustrades from Sapphire Balustrades are part of the cutting-edge design of a confectionery research and development centre for a world leading company. Sapphire’s unique balustrade design and offsite manufacturing service was combined with fast track installation, helping to reduce construction time and cost. Detail planning and sequencing of on-site works enabled frameless structural glass balustrades from Sapphire’s Crystal range to be installed to gallery-style landings over two storeys without the need to use access scaffolding.

The multi-million pound building includes a vast roof-glazed atrium which provides the perfect showcase for spectacular chocolate sculptures. Uninterrupted by balusters (uprights), over 100 metres of free-flowing glass balustrades to central stairways and landings enhance the sense of light and space inside the high-tech facility. The balustrades, which include complex curved sections, were manufactured by Sapphire from clear toughened and laminated glass panels. The 42mm diameter satin polished stainless steel handrails are slotted directly onto the glass for a seamless appearance. Sapphire’s close attention to design detailing is demonstrated in a custom-designed stainless steel trim to the outer face of aluminium base fixings. The aluminium base channel is a registered design of Sapphire which clamps the glass using dry fixed wedges. This enables individual panels to be installed or replaced with minimal impact and cost.

The use of glass and stainless steel is continued in balustrades to a second staircase in the confectionery development centre. For this area of the installation, 10mm glass infill panels are combined with 50mm tubular balusters and handrails in satin polished stainless steel from Sapphire’s Onyx system. Staircase handrails are connected to balusters with stalk-type fixings: balusters are side-fixed on stair sections and top-fixed on landings. In addition to meeting the prestigious project’s aesthetic specification, all balustrades were designed by Sapphire to comply with the relevant standards and legislation relating to structural performance and design loads.

Nick Haughton, Marketing Manager at Sapphire Balustrades, believes the company’s concept-to-completion support is the key to designing high quality balustrades and to minimising time and hassle on site. “And we’re always looking for innovative ways to make it easier to create compliant designs,” he says. Recent developments at Sapphire include CABS - Computer Aided Balustrade Specifier - a free online tool which guides users through the design and specification process and offers recommendations, such as handrail diameter and glass infill thickness. Other free support services include Sapphire’s popular SES - Structural Evaluation System - which can be used for producing bespoke structural calculations for individual balustrades or handrail projects using Sapphire’s comprehensive range of systems.

Stylish balustrades from Sapphire ensure sweet success for Confectionery Development Centre

| T | (0344) 88 00 553 |

|---|---|

| F | (0344) 88 00 530 |

| E | support@balconies.global |

| W | Visit Sapphire Balconies Ltd's website |

| UK Head Office, 11 Arkwright Rd, Reading, Berks, RG2 0LU |