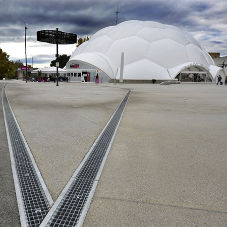

If you visit Rennes, the one place you must see is Place Sainte-Anne, located in the northern part of the city’s old town. This square is home to an enormous church called the Basilique Notre-Dame de Bonne Nouvelle de Rennes.

In this spectacular square, ULMA installed their drainage channel systems with two objectives in mind: to provide a technical solution for draining rainwater, and to do so using an aesthetically pleasing grating.

Technical drainage: MultiV+ channels (and why they should interest you).

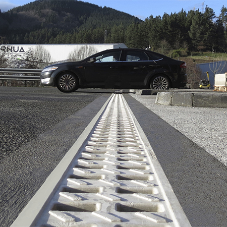

ULMA's most widely used system is the MultiV channel drain

> Durability over time: Made from polymer concrete, they are up to four times more durable than traditional concrete channels. As such, the drainage system will last much longer.

> Reduced cleaning costs: the optimised V-shaped channel causes the water to drain faster, helping to remove sediment more effectively and thus provide self-cleaning properties. In other words, these channels require less maintenance because they clean themselves.

> Savings on labour costs: thanks to the Rapidlock® screw-free fixing system, the grating can be fixed to the channel in just a second, with no need for tools. Quick and easy.

For Saint-Anne, ULMA supplied two different models from the MultiV+ range: The R200GH1 channel model with a mixed slope and low-profile channels.

The mixed slope—which is pre-sloped but, also with a cascaded slope—is perfect for draining long sections, as it optimises the hydraulic capacity. Installations with a slope also have another added benefit enabling the channels to be connected to the existing water network.

In addition, for cases where a low water supply line was required ULMA chose the R200GH8 low-profile channels. The external width of these channels is 236 mm and the total height is 80 mm.

So, how did ULMA meet the aesthetic part of this challenge?

Since this is an urban environment, the appearance of the grating was an important factor. In this case ULMA installed heel-proof longitudinal slotted gratings. This type of grating is equipped with 45° water directing slits and pivots and has a catchment area of 720.55 cm²/ML.

Technical and aesthetic drainage solution

| T | (+44) 0754 2982 022 |

|---|---|

| 0793 221 5849 Tech Dept. | |

| E | mikelgarcia@ulmaarchitectural.com |

| W | Visit ULMA Architectural Solutions's website |

| Unit 20B Access 18, Avonmouth, Bristol, BS11 8HT |