The amendments made to Approved Document B since 2019 have had a wide-ranging impact on the design of facades across the residential sector. In short, the amendments prohibit the use of combustible materials on the façades of buildings in excess of 11m high. There are various qualifications on the types of buildings that this affects, but they have specifically focused attention on the specification of products on building facades.

So, what are the key considerations to be made when applying these changes to balustrade systems?

1. The most well-publicised impact is on the use of laminated glass in balustrades. A traditional laminated interlayer is not considered to meet the minimum fire rating requirements. Therefore, if there is a need for a laminated glass balustrade then an a2-rated interlayer is required. In systems that use this a2-rated laminated glazing, there is also a requirement for a capping trim framing each glazing panel.

2. Powder coating finishes also need to be compliant with the minimal fire rating requirements. It is important that both the protective coating and the powder specified to be applied to the balustrade have adequate certification in line with the A2-s1, d0 standards.

3. A less well-known area for consideration is the use of glass ‘wedges’, packers and thermal breaks. Although there is an exemption within approved document B for “seals, gaskets, fixings and sealants”, interpretation of how this applies to balustrade varies from project to project.

Taking each consideration in turn

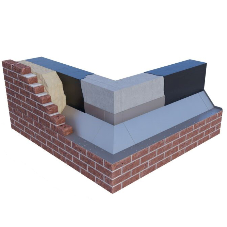

a. Plastic structural ‘wedges’ are used in some glass balustrade systems to secure the glass within the base channel. It is important to specify a balustrade that uses a non-combustible cementitious grout to secure the glass in the channel.

b. Structural packers are used to level balustrade posts and base channel on concrete substrates. Again, traditional structural packers are combustible plastic products. It is therefore important that non-combustible metal packers are used for this application.

c. Lastly, thermal breaks are required for balustrade posts or brackets in some instances to prevent heat transfer from the balustrade to the substrate below. Again, there are both combustible and non-combustible options on the market and they should be specified in line with the regulations

Their technical sales team would be pleased to support you with your next project, contact us via the specification request form and they'll do the rest!

You can also access their technical downloads library via their ‘Contact us’ form. The library hosts a variety of typical details for all their systems and can be accessed with a secure link and password.

They look forward to hearing from you soon!

The 3 key considerations when applying the Approved Document B requirements to BA Systems

| T | (01603) 722330 |

|---|---|

| F | (01603) 722777 |

| E | ben.hynd@basystems.co.uk |

| W | Visit BA Systems's website |

| 22 Bidwell Road, Rackheath Ind Est, Norwich, Norfolk, NR13 6PT |