Thermostatic mixing valves (TMVs) are used to blend hot and cold water and maintain this at a set constant outlet temperature. This ensures safe and comfortable hand washing, shower and bath temperatures. This significantly reduces the risk of scalding. There are three types of TMV, each used for applications with differing regulations. This article looks to explore TMV valves with TMV2 and TMV3 approvals, which are specifically tested to ensure that they meet industry standards for use in domestic, healthcare and other applications where vulnerable persons are present. We’ll explain the difference between each valve type and their applications, as well as the regulations controlling them.

How does a thermostatic mixing valve work?

Before we can get into the differentiators between each, it’s worth exploring how TMVs work. Fully immersed in the mixed water outlet port is a temperature sensor, which is the controlling element of the TMV. The valve expands or contracts accordingly to continually maintain the correct proportion of hot and cold water entering the valve.

This is also the case for tempering valves, however the difference here is that a tempering valve is usually for delivery of water at much higher temperatures unsuitable for the intended applications of TMV2 and TMV3 valves. Tempering valves are used in systems where the temperature of water in the storage cylinder can exceed 60ºC, such as in solar heating systems with multiple outlets or as part of recirculating domestic hot water systems.

Before the introduction of the TMV accreditation schemes in the late 90s, there were few regulations in place to help protect vulnerable people against scalding. In order to tackle this issue, regulatory schemes were introduced in both domestic and healthcare environments to protect people, namely young children, the disabled and the elderly. Thermostatic mixing valves are classified by their suitability for installation in certain buildings by undergoing rigorous testing by independent group NSF International (formerly Buildcert). Details of each scheme are discussed below to help you understand whether you should be using TMV2 or TMV3 approved valves for your application.

TMV2 scheme

TMVs are installed in both domestic properties and other domestic type environments. TMV2 valves are designed and tested to be used in domestic environments in order to reduce the risk of scalding at home. In 2010, the TMV2 scheme became part of the British building regulations to control the temperature of hot water to a safe maximum in domestic bathrooms, specifically for baths and bidets. The regulations apply to all new build domestic properties in the UK, along with homes where bathroom renovations are being undertaken involving any movement or replacement of bath, bidet or shower outlets.

TMV2-designated thermostatic mixing valves are compliant with BS EN 1111 (high pressure) and/or BS EN 1287:1999 (low pressure). The UK Building Regulations Part G requires mixing valves that are compliant with BS EN 1111 and/or 1287:1999 to reduce the risk of scalding. NSF International delivers TMV2 testing and certification against the updated performance standards BS EN 1111:2017 and BS EN 1287:2017.

TMV3 scheme

This scheme applies to thermostatic mixing valves for use in high-risk commercial healthcare applications within the UK. These valves offer a high level of protection, reacting much more quickly in shutting off the flow of water if the cold water fails, or a safe temperature is exceeded. Testing bodies must ensure that the valve adheres to the NHS D08 regulatory standard, which ensures stable temperature output despite varying supply pressures and temperatures.

Other important factors taken into consideration when carrying out performance testing for both TMV2 and TMV3 accreditation include:

● The company/manufacturer applying for accreditation of the valve must prove their compliance with ISO 9001 (or equivalent quality management system)

● The valve must feature the correct markings making it identifiable in the field

● The installation and maintenance documents must include information stated by the scheme

TMVs and legionella

The recommended temperature range for delivery of safe hot water where a TMV is installed is 39° - 43°. The maximum mixed water outlet temperatures for both TMV2 and TMV3 valves are outlined in the table below:

The conflict between delivering water at safe temperatures and fighting off harmful legionella bacteria should always be taken into consideration with TMVs. Water should be stored below 20°C or above 60°C to prevent the growth of legionella bacteria, which can be extremely harmful and even fatal if exposure occurs. As TMVs allow for high temperature water storage the risk of bacterial growth is reduced, however it is not eliminated altogether.

The location of the TMV plays an important role here. Any space between the TMV and outlet where blended water is stored provides a breeding ground for such bacteria. For this reason, it is recommended that:

● TMVs are installed as close to the water outlet as possible, mixing water at the point of use where possible

● Multiple TMVs should be used in the case of multiple outlets; use of a single TMV increases the risk of bacteria growth

Servicing and maintenance of Thermostatic Mixing Valves

Ensuring TMVs are serviced and maintained regularly can help ensure that the valve is still delivering water at the required temperature to prevent scalding.

With this in mind, it is highly recommended that TMV valves are checked and maintained regularly (once a year) to ensure they are still providing the required and intended protection. The outlet temperature should be tested to check that there is no significant change (≤ 2°C) and the failsafe shut-off activates as intended. If the TMV does not meet these requirements a full TMV service plus recommissioning, or valve replacement will be required.

The valve and filters, strainers and any other components forming the device should also be inspected, cleaned, descaled and disinfected.

Altecnic’s TMVs

Altecnic provides a comprehensive selection of thermostatic mixing valves tailored for a wide array of environments, including domestic, healthcare, educational, hotel, and leisure facilities. Our TMVs boast accreditation from WRAS, TMV2, TMV3, and DTC, ensuring quality, reliability, and compliance with industry standards.

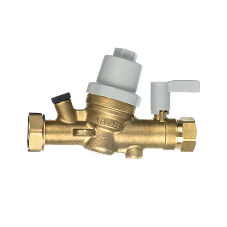

TMV2 & TMV3 : MERCHANT MIXING VALVE - SERIES 5213

TMV3 : MIXCAL CAREFLO PLUS® THERMOSTATIC MIXING VALVE - SERIES 5213+

Related CPDs:

The History of Legionella & Legionnaires Disease

Legionella Considerations When Reactivating Buildings

Thermostatic Mixing Valves

TMV2 and TMV3 What do you know about them?

| T | (01785) 218200 |

|---|---|

| F | (01785) 218201 |

| E | barbour@altecnic.co.uk |

| W | Visit Altecnic Ltd – Caleffi Group's website |

| Mustang Dr, Stafford, Staffs, ST16 1GW |