Understanding the data and what it means:

When designing and specifying a floor build-up, the importance of accurate and reliable compressive load data cannot be underestimated.

Why is compressive load data important?

Any element of the build that receives a load should be tested in order to ensure that it is capable of resisting that imposed load.

There are two test standards for compressive load testing; one of the standards assesses product’s ability to resist long-term static loads, whilst the other determines the resistance to short-term temporary loads. Naturally, the short-term test results are generally much higher than the long-term static load results.

This is especially noticeable when analysing the test results for insulation, as many manufacturers will use the higher temporary load figure in order to advertise their product.

Misleading data such as this has the potential to create significant issues, including the specification of products that do not possess the necessary load capabilities.

What is the compressive load data for Newton’s products?

Using the right test data.

The meaningful compressive load test for insulation is BS EN 1606, which assesses the compressive creep performance of thermal insulation materials over an extrapolated 50-year period and determines the maximum load that can be applied to the product without reducing the thickness by more than 2%.

Only BS EN 1606 should be considered as a safe assessment of the potential use of the material within a floor build, as other test standards are not applicable.

Newton therefore decided to analyse the data used for products in the UK Cavity Drain Membrane (CDM) market and found that manufacturers and suppliers were publishing the temporary load figures on their product information (not the long-term load figures).

The result is a plethora of confusing and varying data being presented by different companies.

Testing the Compressive Load of Cavity Drain Membranes

The standard for testing the load capability of cavity drain membranes in ISO 25619 “Geosynthetics – Determination of compression behaviour”, comes in two parts:

Part 1: the long-term compressive properties of the material.

Part 2: the short-term compressive properties of the material.

Newton’s cavity drain membranes

have all been tested to ISO 25619-1, which judges a product to have failed if it compresses by more than 10%. However, Newton also worked with Kiwa to test our membranes to the same performance level as BS EN 1606.

Test results

For the results of these tests, please view the technical article on the Newton Waterproofing website. To request the full test results and test certificates, contact the Newton Technical Team on 01732 360 095 or at tech@newtonwaterproofing.co.uk.

How does Newton’s data compare to other products?

Newton’s cavity drain membranes are the only products currently available that have meaningful test data to support the long-term compressive capability of the membranes.

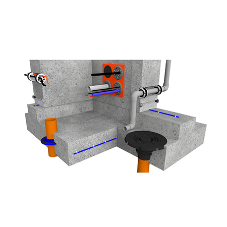

What does this mean for Type C waterproofing systems?

Designers and specifiers are now able to accurately understand the impact of long-term compressive load on cavity drain waterproofing membranes.

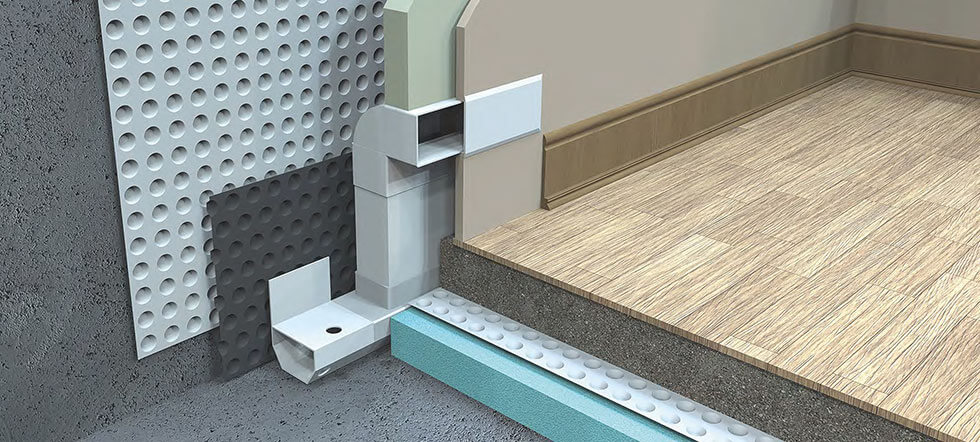

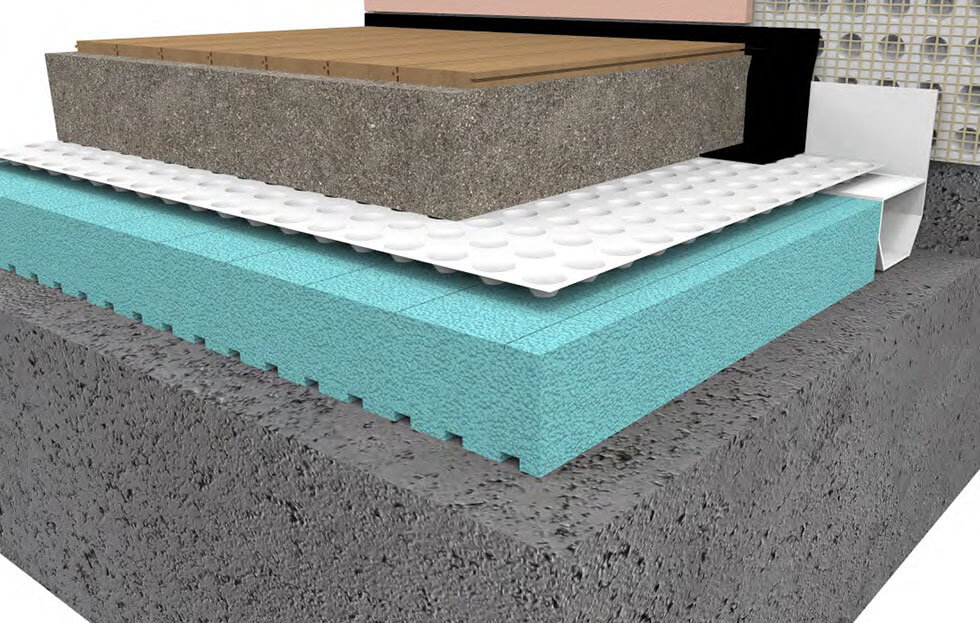

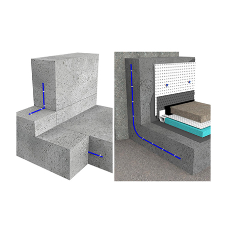

Most Newton waterproofing designs will specify that the membrane studs should be filled with screed, and as a result the membrane load capability is always 800 kPa (or 81.58 tonnes per square metre).

The primary weakness in the floor build is therefore the Fibran XPS 500-C insulation spacer, so it is the long-term compressive load capabilities of this product that should be the main consideration.

Summary

Overall, there are three clear takeaway points regarding product performance under long-term compressive loads:

1. Newton are the only supplier of cavity drain membranes that have accurate and meaningful test data for the capability of their membranes to resist long term compressive load and not deform more than 2% over 50-years.

2. Newton are also the only supplier of cavity drain membrane systems that have accurate data on the capability of the insulation used below the floor membranes to resist long-term point loads.

3. Lastly, Newton Fibran XPS 500-C is the only insulation that has test data supporting its ability to resist compressive point load and not deform by more than 2% over 50-years.

For more information on this technical article, or to speak to their Technical Team, please call 01732 360 095 or email tech@newtonwaterproofing.co.uk.

Compressive load capabilities of Type C waterproofing

| T | (01732) 360095 |

|---|---|

| 01732 360095 Tech Dept. | |

| F | (01732) 359033 |

| E | tech@newtonwaterproofing.co.uk |

| W | Visit Newton Waterproofing Systems (John Newton & Company)'s website |

| Newton House, 17-19 Sovereign Way, Tonbridge, Kent, TN9 1RH |