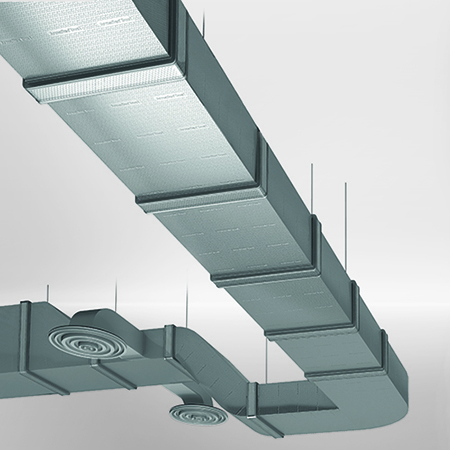

Ducts that transport cool air need a good thermal insulation solution in order for the required supply temperature to be maintained. By preventing heat gain transferring from warmer air outside the duct, the correct insulation material ensures a more efficient HVAC system operation, with less power required to maintain the cold air supply temperatures.

Condensation

For cold air supply applications a key consideration is prevention of condensation on the outside of ducting in warmer ambient and high humidity conditions. Increases in relative humidity levels in particular have a dramatic effect on the thickness of insulation required, and failure to adequately insulate ventilation systems in these conditions can lead to expensive consequential damage and corrosion of ductwork.

On the other hand, the correct choice of insulation material, with adequate space allowed for air flow around the ducting to prevent cold build up zones, will ensure the surface temperature of cold air ductwork is kept above the ambient temperature, preventing ductwork surfaces from falling below the dew point.

Elastomeric insulation

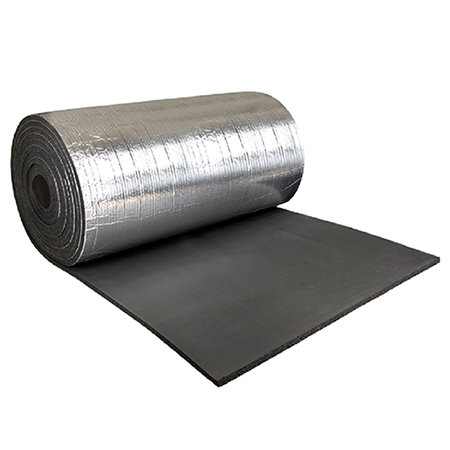

Nitrile rubber sheet provides a number of advantages for cold air ducting, owing to the closed cell structure providing an in-built resistance to condensation and water vapour ingress, with no additional vapour barrier required. Mineral wool and phenolic alternatives are reliant on the integrity of an external foil vapour barrier to prevent moisture penetrating and wicking through the insulation. Any gaps or pin holes in the system can lead to moisture ingress and a loss of thermal performance.

Closed cell products with a high resistance to water vapour transmission (mu factor) built up throughout the material thickness can provide a longer term thermal performance, with a low thermal conductivity (for example 0.033 w/m • K for AF/Armaflex Class O nitrile rubber). The black rubber material also has a higher surface emissivity value, helping to bring the outer temperature above the dew point, with reduced insulation thickness required compared to shiny / reflective finishes.

Installation considerations

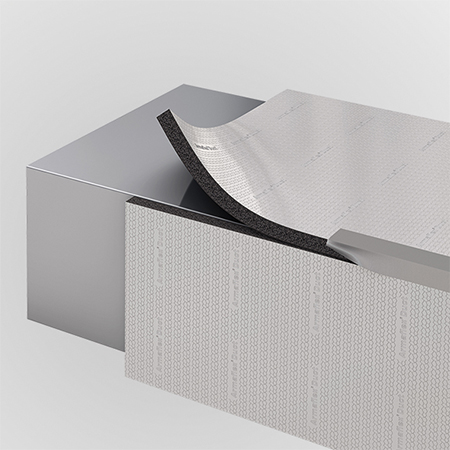

The flexible properties of elastomeric rolls and sheet also provide a good solution when it comes to installation. The sheets can be easily cut to size for rectangular panels, bends and supports and to exactly fit around the circumference of circular ducting. Sections are cut with an additional 5mm to allow for compression sealing and to accommodate expansion and contraction of the material once the system is operational.

This method ensures no gaps are left and use of the appropriate adhesive on all longitudinal and circumferential joins provides a seamless vapour seal against condensation on cold air supply systems. Higher density duct supports sections are available with PET inserts to prevent compression at hangers and Armaflex tubes can be used to encapsulate and cover flanged joints to prevent thermal bridging.

Nitrile rubber is suitable for operating temperatures down to -50°C and have a Class O fire rating for use in commercial premises such as offices, hotels, schools, hospitals, supermarkets, shops and process applications.

For aesthetic considerations nitrile rubber sheets are available with an alu foil facing. For additional mechanical impact resistance and protection against damage from birds and vermin, sheets with a pre-applied PVC covering are also available. Sheets with the covering may be secured with compatible tapes and mastics for weather proofing outdoors. On rectangular ducting, horizontal sheets should overlap insulation on the vertical panels to prevent moisture damage. On circular ducting a 50mm overlap on the covering should be sealed on the underside of the duct, facing downwards (water shed effect).

All sheets are available with a self-adhesive backing for fast fixing in place or can be glued in place using a suitable contact adhesive.

Acoustic and anti-microbial properties

Nitirle rubber products such as Armaflex also provide significant sound absorption advantages. When used as an external acoustic lining, noise break-out from the duct wall can be significantly reduced. Isolating ducting from hanging brackets also reduces the transfer of sounds reverberating through the structure of the building.

AF/Armaflex Class O also comes with Microban anti-microbial protection built-in, offering enhanced resistance against bacteria and mould growth. This makes AF/Armaflex Class O suitable for use in offices, schools and hospitals.

View AF/ArmaFlex Class O Product Entry View Armacell UK Product Catalogue PDF