The Paoli-Calmettes cancer treatment centre in Marseille is using Schöck Combar glass fibre reinforcement for the foundations of its groundbreaking equipment that combines MRI and external-beam radiation therapy.

The Schöck Combar was installed for both its strength and its ability to guarantee no electromagnetic interference.

Unlike conventional X-ray scanners the ‘MRIDIAN’ does not utilise ionising radiation. It focuses solely on the tumour, leaving the surrounding tissue unharmed – even if the affected organ is moving during the procedure.

The new high-tech system weighs over ten tons and cost around £7m.

To ensure the highest levels of precision, two main installation challenges had to be overcome – the foundation strength and the avoidance of any electromagnetic interference. Schöck Combar glass fibre reinforced polymer was the ideal solution. A load bearing reinforcement that absorbs tensile forces in concrete and is also completely non-metallic – so no risk of electromagnetic interference.

Structural engineer Jean-Luc Galéa explains: "The ‘MRIDIAN’ generates a strong magnetic field and can respond very sensitively to electromagnetic interference, impairing imaging precision. No iron whatsoever may be present in any of the materials within the safety zone and that includes the concrete reinforcement. We opted for Schöck Combar as it met all the technical requirements and has very reliable certifications." The strength of Combar was vital too, given that the foundations had to support over ten tons of technology (a required load-bearing capacity of over 5000lb/m2).

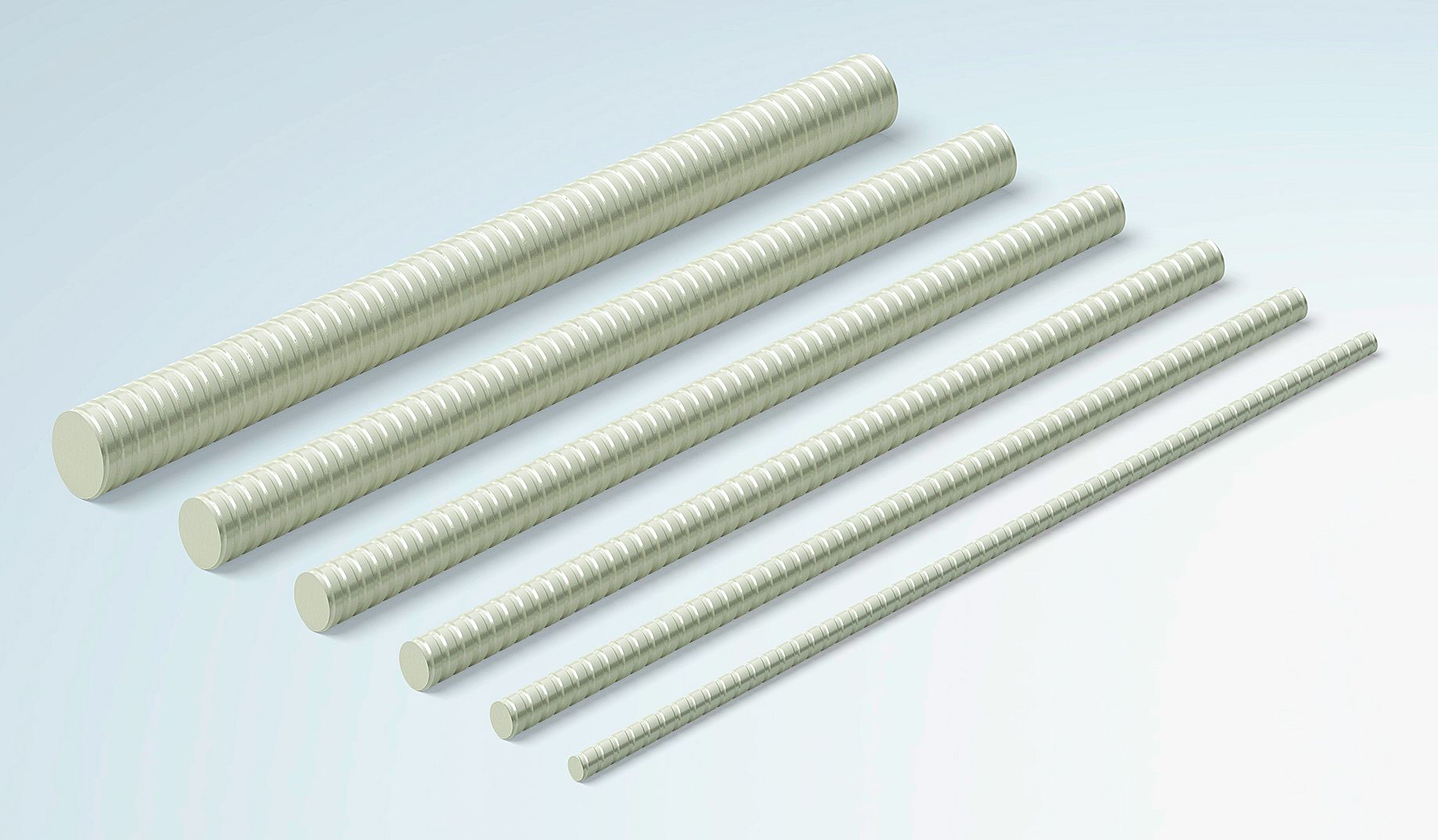

Initial foundation work involved micropiles anchored more than ten metres deep. The centre of the reinforced concrete floor slab was then cut out around where the ‘MRIDIAN’ had to be insulated, leaving an octagonal outline. Anchors were placed at various planes on each of the eight sides and Combar rods inserted top and bottom of each edge to act as reinforcing anchors. Then, alternating rods were inserted to absorb the shear loads.

General contractor Stephane Roldan: "To reinforce the upper and lower levels, we created grates, each made up of 12mm diameter Combar rods. The rods are sturdy, but easy to machine and the plastic clips, ties and spacers were very useful in allowing fast and accurate placement”.

For decades, steel rebar has been used as reinforcement in concrete construction. But steel, although strong, is not an ideal solution, especially in corrosive and electromagnetically sensitive environments. Schöck’s Combar (‘composite rebar’) has been developed as an alternative.

In addition to medical and research facilities – where sensitive instruments can be signifcantly affected by conductivity from steel reinforcement – there are a number of other applications for Combar.

• Boring machines, when used in shaft walls of tunnels, have a problem as they cannot drill through steel reinforced walls. With Combar the machine can cut directly through the head wall.

• Bridges, marine and harbour constructions benefit from Combar as any corrosion risk, even from salt, is eliminated.

• In high voltage transformers and power plant reactors, inductive currents are generated within the reinforcing steel. The heat will affect the rebar strength if too close to the coils. Combar remains unaffected.

View Glass Fibre Reinforcement Schöck ComBAR Product Entry

resized-comp212922.jpg)