When planning to waterproof a basement conversion, the key is choosing the right product to achieve the degree of waterproofing required for the intended use of the basement.

If the basement conversion is going to be used for habitable accommodation it needs to be totally dry with no water or water vapour. You have two choices.

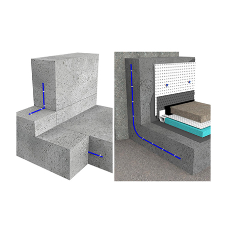

1. attempt to hold water back by applying a cementitious system to the basement (Barrier Option) or

2. install a cavity drain system which will manage and expel any water ingress prior to damaging internal finishes (Cavity Drain Option)

A. Barrier Option

This barrier will require preparation by a trained waterproofing expert. To make it 100% watertight means 100% workmanship which keep in mind is very difficult to achieve. In all circumstances with an internal barrier, for it to be effective you will need to do not only the walls but also the floors. Make sure you have a good existing slab here or even a new one to make it effective.

Disadvantages:

• Any applied system will need preparation to the substrate prior to application which can prove very disruptive and messy and a real problem in general. Depending upon the substrate you may have to rake out the mortar joints, sand blast, scabble, hack off to get back to the substrate and prepare it ready for the applied barrier.

• Wet trades are introduced, as you are potentially making a wet project even more damp by introducing a wet solution. This introduces problems with the waterproof barrier in terms of drying times. Drying out times are one of the most frustrating elements of the barrier approach this can significantly impede a building programme especially when it comes to be able to decorate the finish project

• Inability to fix things like shelving units into the barrier without puncturing the barrier. This will also invalidate any guarantee that was offered by a professional installer.

Advantages:

• The biggest advantage with the barrier is if placed perfectly it will negate the need for installing any form of sump system which saves on future maintenance costs.

B. Cavity Drain Option

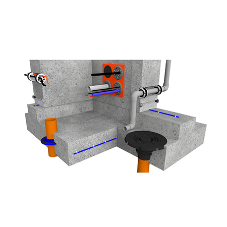

This would be the recommended solution. When waterproofing an existing basement with this system you will have a series of dimpled sheet membranes (usually 8mm in depth) which are mechanically fixed back to the building fabric using a waterproof MultiPlug (plug with a waterproof seal which acts like a rawl plug that you can fix into) then depending upon the finish required either a plain 8mm membrane with battens on plugs or a frame work tied back into the plugs or a meshed dimpled sheet which you can render onto. These systems act as water management system in your existing basement, moving any moisture or water behind the dimples and down to a internal drain which are installed at the wall floor junction. The drain can then either feed out to an open elevation or to an existing drain or a sump and pump.

Advantages:The drained cavity has many advantages the main ones being:

• Minimal surface preparation required, if any

• Can be installed with no wet trades or drying out times

• Can be decorated quickly if an independent dry lining frame is used

• Does not push water to other areas of the project – as could happen with a barrier

• Can be used on all Listed Buildings as it is fully reversible – barriers are not

• Newton System 500 is maintainable – a requirement of BS8102:2009

• The integrity of the system is not dependent on100% defect free workmanship, which conventional tanking is

Disadvantages:

• The biggest disadvantage is that if you are below invert level you will need to use a pump which will mean ongoing maintenance.

Advantages Of Newton System 500 Cavity Drain Waterproofing

Unlike conventional tanking/barrier waterproofing, Newton System 500 places designed maintainable depressurization voids at known weaknesses in the structure so that problem water is simply captured and diverted out of the property. It is recognized by the British Standard and industry experts as the “least likely system to fail”. Newton System 500 comprises wall and floor cavity drain membranes, a drainage system and a sump pump. The system can be installed in all weather conditions, and is easily repairable should the membrane be damaged by other trades.

Installation and Approved Contractors

The most important thing is to make sure whatever system you use you need to get a professional waterproofing contractor to undertake the works. Newton Specialist Basement Contractors (NSBC) are an elite group of professional waterproofing contractors who work in partnership with John Newton & Company to provide the specifier and their clients with the highest quality products, design and installation available in all aspects of domestic and commercial waterproofing.

Waterproofing an Existing Basement – Download Guide

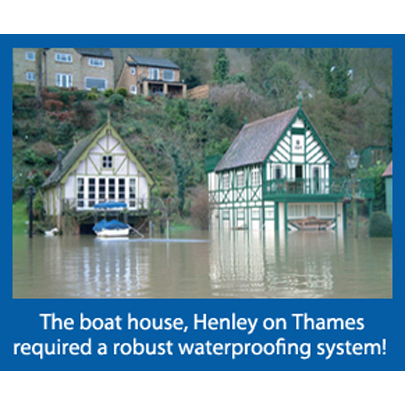

Case Study: Waterproofing The Boat House, Henley-on-Thames

The boat house in Henley-on-Thames was a truly unique project, and the owners got in touch with John Newton & Company following flooding which saw water levels reached up to 500mm internally. Newton System 500 provided the ideal solution for this unique project, as it works by redirecting the water, rather than trying to hold water back – which would be impossible under such pressurised conditions.

Newton 508 Mesh was chosen for the walls, Newton 520 to the floor with a Newton Basedrain ring around the perimeter. Two Newton Titan Plus pump systems were used, which included a battery back up system. Rather than holding water pressure back, therefore, it was accepted that the river would penetrate the structure and would be pumped out.

The full waterproofing system was installed in little over a week. The major test came when the River Thames rose against the property to a depth of over one metre! The Newton System 500 waterproofing system coped with the water ingress as designed. At the height of the flooding all three pumps in each sump chamber were operational. The system proved to be fully successful.

Our client can now happily eat his breakfast in bed watching the boats float past his window, in the confidence that his property is completely dry!

Waterproofing A Basement Conversion: A Quick Guide

| T | (01732) 360095 |

|---|---|

| 01732 360095 Tech Dept. | |

| F | (01732) 359033 |

| E | tech@newtonwaterproofing.co.uk |

| W | Visit Newton Waterproofing Systems (John Newton & Company)'s website |

| Newton House, 17-19 Sovereign Way, Tonbridge, Kent, TN9 1RH |