Concrete blockwork remains one of the most cost-effective methods of controlling airborne sound, making it a natural choice for constructing partition and separating wall. Meeting sound insulation standards is a key requirement for most building types.

Standards

The acoustic standards contained in Part E of the Building Regulations have been in force since 2004. They cover a number of building types including flats and apartments, semi- detached and terraced housing, hotels, hostels, nursing homes and student accommodation.

These Standards do appear to be effective in eradicating noise complaints and thus achieving a better quality of life for building occupants.

Sound performance targets, particularly those limiting sound transfer between adjoining dwellings, are specified in Approved Document E1 to the Building Regulations.

For separating walls and floors in attached houses or apartments, the airborne performance to be met is 45 dB DnT,w + Ctr (or 56 dB DnT,w in Scotland).

This performance is applicable to sound frequencies from 100 Hz (low frequency) to 3150 Hz (high frequency).

Achieving enhanced levels of sound insulation

There is often a requirement for walls in non-domestic buildings to achieve a higher level of sound insulation. Commonly, the performance of building elements will be described as a weighted sound reduction index, Rw.

This term describes the airborne sound insulating power of a building element. It is a laboratory-measured value as defined in ISO 717: Part 1. It can apply to walls, ceiling/ floors, ceiling/roofs, doors, or windows. The higher the number, the greater the sound insulating power of the building element.

It is measured over the frequency range 100 to 3150Hz. Depending on its composition and density, and any applied finishes, standard blockwork construction can provide an Rw of up to around 57dB.

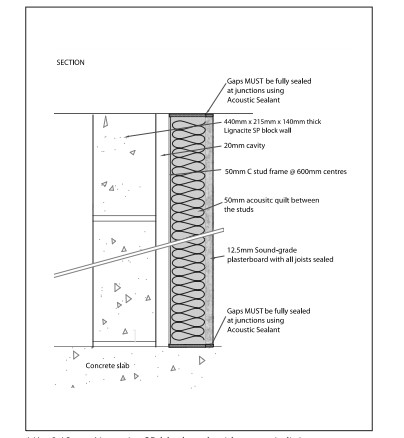

An example of a higher performing construction is the use of a 215mm Lignacrete dense block wall with a plaster finish. Where a greater performance is required, consideration should be given to using concrete blockwork with an acoustic panel to one side.

Lignacite’s research and development team have evaluated a number of blockwork/ acoustic panel combinations, with surprisingly good results.

Typically an acoustic panel will comprise a 50 or 70mm ‘C’ stud frame, set back about 15mm from the face of the blockwork, with acoustic quilt or a proprietary board, such as Isomass, between or over the studs and finished with high density plasterboard.

The advantage of this construction is that it allows blockwork to be used fair face one side, e.g. facing a sports hall, as well as meeting fire and stability requirements. The blockwork and acoustic panel act together to provide raised levels of sound insulation.

Tests commissioned by Lignacite Ltd. in a UKAS approved laboratory has shown weighted sound reduction index values, Rw, of up to 65dB can be achieved.

For further details on the Lignacite range of concrete blocks, please call 01842 810678, email info@lignacite.co.uk, or visit Lignacite's website.

Achieving enhanced sound insulation performance using Lignacite blocks [BLOG]

Lignacite

View company profile| T | (01842) 810678 |

|---|---|

| 01842 810678 Tech Dept. | |

| F | (01842) 814602 |

| E | info@lignacite.co.uk |

| W | Visit Lignacite's website |

| Head Office, Norfolk House, High St, Brandon, Suffolk, IP27 0AX |