Improved energy efficiency and sustainability remain priorities for building designers and their clients. In this article Armacell discusses how simple, cost effective steps within the distribution system can help achieve these objectives.

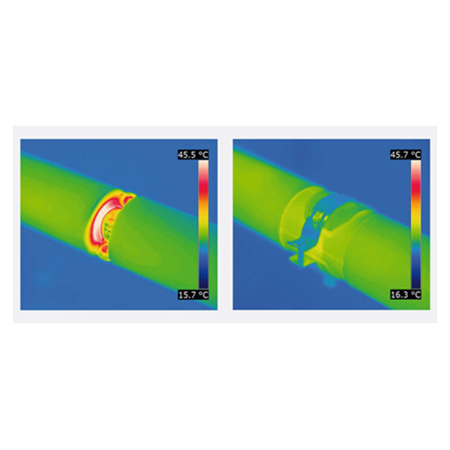

Pipework in HVAC systems is usually insulated as a matter of course, in line with building regulations, although pipe supports are often overlooked. That means these critical points, which in a large system can number several hundred, remain un-insulated. This results in significant heat losses in a system, with the consequences being reduced energy efficiency and deterioration of assets due to condensation.

The effects of pipe brackets not being insulated can increase total energy costs of running a facility, especially where a large number of supports are used. It’s worth bearing in mind that each uninsulated pipe bracket loses around £2.00 each year in wasted energy and, considering the number of brackets in a system, this can soon add up to a significant amount.

When it comes to cold water systems, condensation can be an issue when pipe brackets remain uninsulated. Aside from the wasted energy costs, this moisture results in rapid deterioration of metallic components, reducing its life as well as causing contamination issues, which is a concern in certain production environments such as food and pharmaceutical. The best method of preventing condensation is to avoid direct contact between the pipe and its bracket by using insulated pipe supports.

When choosing an insulated pipe bracket for both hot and cold applications, closed-cell elastomeric nitrile rubber insulation, which has a high resistance to water vapour transmission and low thermal conductivity, is best able to protect against energy losses and condensation. Using the same insulation materials for the pipework and support brackets ensures compatibility and allows them to be installed and glued to each other along the entire system.

An increasing number of engineers are choosing to use pre-fabricated elastomeric insulation supports such as Armafix Ecolight, made with 100% recycled PET Foam. The low thermal conductivity value and high water vapour resistance provides protection against energy losses and condensation, whilst the load-bearing segments prevent the insulation material being compressed.

BRE (Building Research Establishment) has added a category for pipe insulation materials to their Green Guide to Specification, with nitrile rubber insulation products such as Armaflex flexible elastomeric foams (FEFs), receiving an ‘A’ rating. Being an independently verified FEF insulation with the highest water vapour resistance and lowest thermal conductivity ratings, ensures that it offers the best long-term solution for ACR applications and a highly efficient option for heating and ventilation services.

Achieving an efficient system is much more than simply specifying an A+ rated device. Building Engineers need to look at the whole system because the boiler, air conditioning unit or other asset does not just sit there in isolation. That’s because connecting an A+ rated asset to a distribution system will immediately impact on its stated energy efficiency. True efficiency comes from the whole system and not just the boiler. Thermally isolating the pipe from its fixing and specifying a closed-cell, A-rated insulation material are simple, low cost but very effective methods of ensuring optimum thermal performance.

View AF/ArmaFlex Class O Product Entry