Insulation manufacturer ACTIS has introduced the HYBRID range - a range of three products aimed at addressing longstanding, DECC recognised, evidence of a performance gap between predicted and actually achieved building energy savings.

ACTIS, known for its innovative insulation products – as the pioneer of multifoils since 1980 and for its wood fibre insulation range launched in 2009 - has developed a new range of thermally efficient products whose performance, once installed in buildings, matches that predicted in the lab.

The trio of products in the HYBRID range has been dual tested in the lab according to EN 16012 and their declared thermal performance has been verified on site according to ISO 9869 by Glasgow Caledonian University. These test address the issue that there may be a difference between how insulation performs in situ and its effectiveness predicted by laboratory test results.

The lab testing sees the products’ thermal performance measured under steady state conditions at a pre-defined temperature difference. Then, once installed in a building, the products are subjected to a range of climatic conditions including wind, humidity and solar effects. On site confirmation of the declared product thermal performance means that its thermal behaviour is under control and cannot be the reason for a building’s performance gaps, which can be as great as 35% according to DECC.

The two performance figures – lab and on site – are similar, thanks to the dual performance nature of the hybrid products, which combine insulation, air tightness, moisture resistance and reflective properties. All are resistant to air infiltration as well as to thermal loss through convection and all have moisture resistant components. They also all have the same unique patterned reflective external film with an emissivity as low as 0.05 which allows them to provide additional resistance value from adjacent air voids.

All hybrid products can be used as standalone solutions or in a combination to achieve the highest U-value requirements with a minimal thickness.

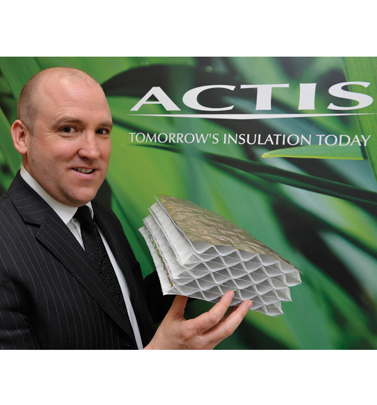

- The new flagship product HYBRIS is a totally new insulation material based on a honeycomb structure made of polyethylene foams glued to aluminium coated foils. Available in thicknesses from 30mm to 300mm every 15mm, it has a core effective thermal conductivity λt as low as 0,032 W/m.K, which, combined with air cavities, can achieve an R value as high as 4.55 m2.K/W in walls with 105mm and 2 air gaps. It can be used to insulate timber frame or masonry walls, pitched roofs or ceilings.

- HCONTROL HYBRID is a vapour control layer with an unrivalled built-in thermal performance and is suitable for use on the warm side of walls and roofs. Available in rolls of 10 m2 and 45mm thick, it complies with EN 13984 for its vapour control properties and also achieves a declared core R-value of 1,90 m2.K/W and an Rvalue of 3,20 m2.K/W with two air voids of 20mm, according to EN 16012.

- And BOOST’R HYBRID is an insulating breather membrane for use on the cold side of walls and roofs. Available in rolls of 10 m2 and 35mm thick, it complies with EN 13859-1/2 for its breather membrane properties and also achieves a declared core R-value of 1,35 m2.K/W and an R-value of 2,40 m2.K/W with two air voids of 20mm, according to EN 16012.

All three products have been fully certified in UK and Europe by accredited bodies and are suitable for use in newbuild and refurbishment projects.

ACTIS UK and Ireland director Matthew King explained: “These three new products provide a complete insulation system for both new build and refurb designers. We made the decision to test them in lab as well as on site, so that we can state exactly how they will perform against the rigour of our great British weather because guaranteed building energy performance is rightly expected. We have used the knowledge we have gained from our experience as in-situ testing pioneers to develop a range of products which hold their thermal performance promises once installed, whatever the weather conditions”.