Whether you’re an architect, specifier or interior designer, at some point you’re going to, or already have, specified automatic swing doors for your project. But how do you make a swing door look aesthetically pleasing to the eye, whilst considering safety sensors and finger-guarding?

Traditionally if you are automating a hinged, swing door you would need to provide the following to ensure it adheres to BS EN16005 legislation – safety at powered doors for pedestrian use:

1-Top rail mounted sensors with one or more modules, mounted in a housing, to provide appropriately varied field widths of infra-red curtains, to detect objects in the path of the opening or closing leaf face.

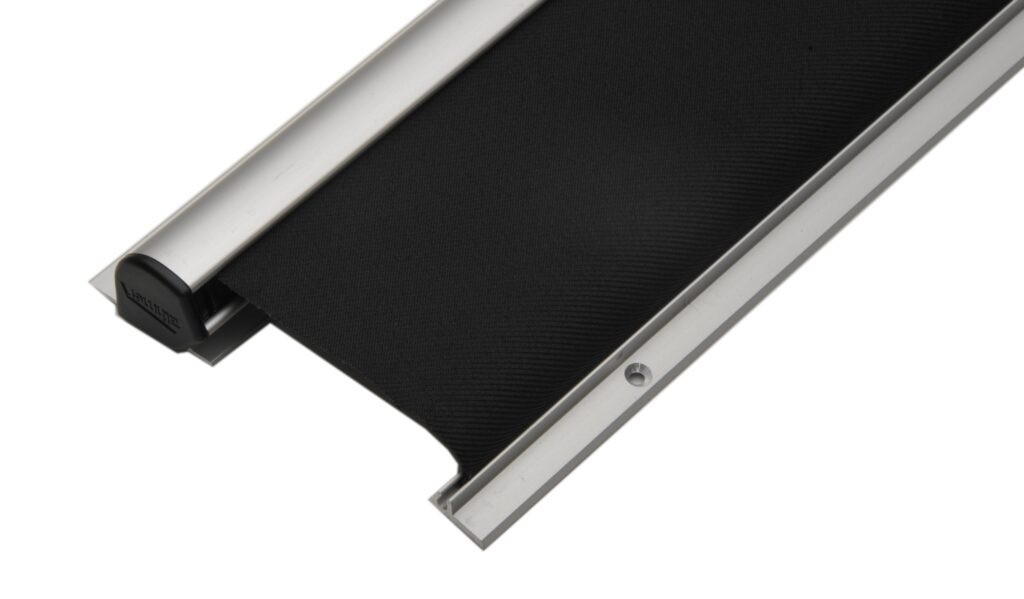

2-“Hinge-safe” or roller-blind finger guarding at the hinge point to prevent fingers from getting trapped.

Although compliant to BS EN16005, this now creates further “challenges” for the architect or specifier, most notably:

- Competition for space on the top rail, with for example, magnetic locks on access control doors, slide track pull arms etc.

- Limitations on the placing of full height handles.

- No suitable or aesthetically acceptable fixing ground on “frameless” door leaves.

- Exposed vertical leading edge with no safety coverage.

The final point is particularly notable in that, although a top mounted rail sensor will “sense” along the door leaf, it falls short of the leading door edge. This means the whole door is not protected and there is a small chance someone may still get struck if they are caught in this blind spot between the end of the sensor field and the leading door edge.

With the Flatscan 3D sensor you could replace all of the above and still provide a safe, compliant door. The Flatscan 3D sensor is a crescent shaped sensor which sits in the corner of any swing door and monitors the whole door leaf as well as the hinge points negating the need for top mounted rail sensors and unsightly finger guard accessories.

Additionally, the Flatscan 3D sensor also senses 10cm passed the leading door edge, meaning a much safer door. With 4 laser curtains sensing along the whole door leaf and hinge points, this sensor encompasses all of the equipment above and more.

Furthermore, with the Flatscan 3D utilising radar technology, the reach of the sensor far surpasses that of the top mounted sensors as shown in the diagram. This enables you to increase your door sizes safely and effectively if required.

The Flatscan 3D sensor also has an additional built-in output to act as activation as well. This means you could potentially negate the requirement for additional push pads or other activation devices.

In today’s world and with the prevalence of Coronavirus, activating automatic doors without the need for touching any surfaces would prove hugely beneficial for the healthcare industry as well as high traffic areas or office environments.

With all this additional safety, laser curtains and technology you would be excused to think this would be a complicated piece of equipment to set up. It’s not. Once installed a simple hand gesture will allow the sensor to perform its “learning process” and scan the environment around the door prior to being fully operational.

It’s quicker to install than the top mounted rail sensors and hinge protectors, it sets itself up quicker and is safer.

In conclusion, if you are working on a project where aesthetics or excessive dimensions are key, or where infection control and cleanliness are essential then the Flatscan 3D would be an ideal solution as a substitute to the top rail mounted sensors and hinge protection finger guards.

Not only will the doors look more aesthetically pleasing, but there are less surfaces for bacteria and infection to make contact with, meaning a safer, cleaner and better looking door for your clients.