This article discusses using Lignacite’s ranges of Concrete and Architectural Facing Masonry blocks (AFM) in refurbishment or retrofit projects.

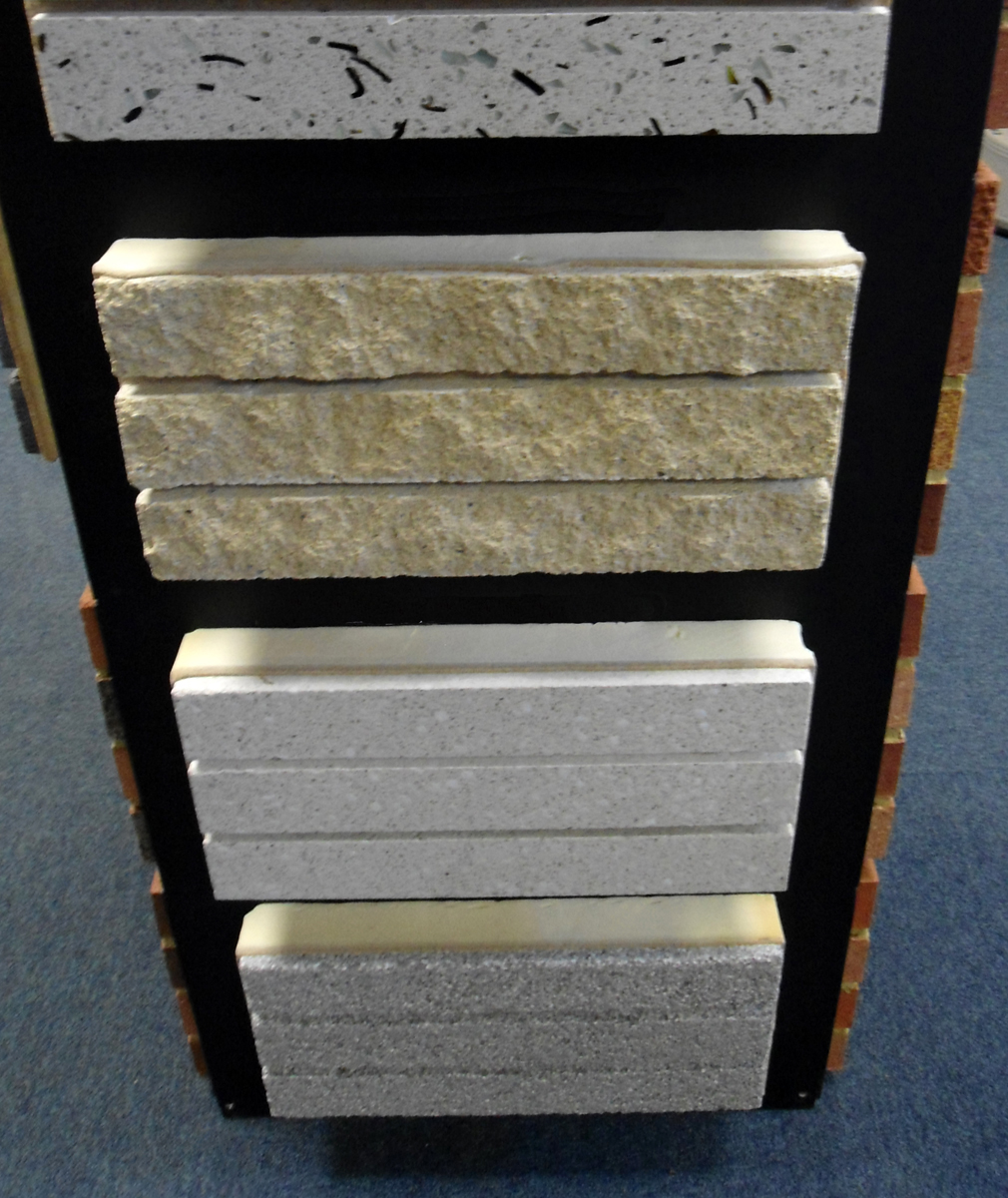

Lignacite offers over 14 ranges of different masonry, including its Architectural Facing Masonry (AFM), which is available in over 300 combinations of texture, colour and size, and its increasingly popular Roman Brick.

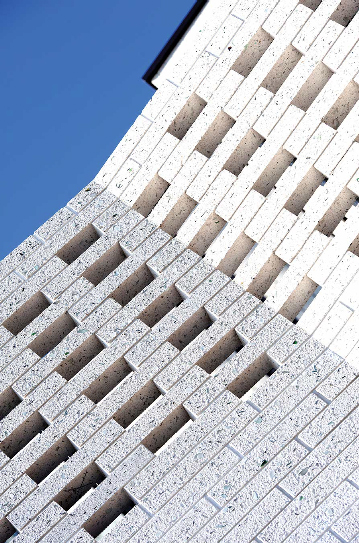

The blocks are used not only in new build projects they have also been used to create interesting wall features on both refurbishment and retrofit projects.

Lignacite’s range of AFM blocks create’s both internal and external decorative wall facades and offers over 50 different colour choices, recently adding the colours Barley, Blackberry, Evergreen and Pale Cream. The full range of colours are combined with a choice of 5 finishes. The Roman Brick module (440 x 65mm) is 1/3rd of the height of a standard block (440 x 215mm) can also be used to create some interesting internal and external wall finishes, whether it be for perimeter walls, decorative panels or in urban landscaping.

Lignacite also manufacture masonry ‘slips’, i.e. slices of facing blocks approximately 20mm thick which are bonded to prepared frameworks or existing walls to create new finishes. One project currently at design stage is a retail space where internal partition walls are to be re-clad with masonry slips alongside other contemporary finishes. Slips of Lignacite Midnight Polished Granite have also been used recently (due to their impervious nature) in a project involving the redesign of a bathroom area. The Roman Brick module is also available in this ‘slips’ format.

In addition to supplying many of the major house builders, Lignacite’s blocks have also been used in a host of major landmark projects. Many of these are in London, and include The Gherkin, The Shard, the Olympic Stadium, Canary Wharf, and Heathrow and Stansted airports.

Lignacite have been involved in a range of major contracts, recent examples of which include Crossrail, where the blocks have been used on a number of new stations, and the development of Battersea Power Station.

Lignacite are also regularly challenged with complex projects such as the building of the MK Dons Football Stadium and Festival House in Blackpool.

The company intends to remain within its core market and area of expertise, however, they are constantly attempting to source new materials which are renewable, such as wood, hemp and straw, or can be recycled and incorporated into their range of products.

Architectural Facing Masonry blocks for refurbs

Lignacite

View company profile| T | (01842) 810678 |

|---|---|

| 01842 810678 Tech Dept. | |

| F | (01842) 814602 |

| E | info@lignacite.co.uk |

| W | Visit Lignacite's website |

| Head Office, Norfolk House, High St, Brandon, Suffolk, IP27 0AX |

Categories

Prefabricated building facades