Marley clay roof tiles have been awarded a ‘very good’ performance rating under the BES 6001 framework standard for the responsible sourcing of construction products.

The rating has been given due to the implementation of a range of sustainability and environmental initiatives such as sustainable manufacturing and a high degree of material traceability from a responsible source. The tiles are manufactured at Marley’s state of the art facility in Keele, which has the largest clay plain tile production capacity in the UK.

BES 6001 is the ‘Framework Standard for the Responsible Sourcing of Construction Products’ by the BRE. Marley’s clay tiles had previously achieved a ‘good’ rating and the reassessment this year resulted in an improvement to ‘very good’, meaning the company achieves the maximum credits towards BREEAM and Code for Sustainable Homes.

Sarah Jackson, marketing product manager at Marley, explains: “Material traceability is an important part of the BES 6001 accreditation.

Our clay plain tiles are manufactured from locally sourced Etruria Marl, which is generally accepted as the finest clay for strength and durability, from a source operating to internationally recognised management systems and BES 6001. This means one of the reasons we score highly is because such a large percentage of the constituent material in our clay tiles is traceable to a responsible source in the supply chain. While this is important, the fact that since our last assessment, we have become the only roofing manufacturer in the UK to achieve independent carbon footprint certificate from the Carbon Trust, also helped us to reach a higher responsible sourcing rating.

“In addition, setting carbon reduction targets and reporting on them to stakeholders is also an important measure within BES 6001, and our latest environmental audit report for stakeholders demonstrated that over the past four years, we have achieved a 13% reduction in CO2 emissions per tonne of product manufactured. Investments in the latest high efficiency lighting and control systems, as well as regular energy audits to highlight inefficiencies and potential areas for improvement have contributed to this.

We have also set ourselves a challenging target of zero waste to landfill by 2015 and we will work tirelessly to achieve this during the next two years. Our clay tile factory at Keele also has a rainwater harvesting system that collects stores and uses the rainwater to reduce the demand on mains water supplies.”

Marley invested £19 million in the Keele clay plain tile factory over six years ago, using ground breaking energy and recycling initiatives to reduce the environmental impact of the factory and the embodied carbon of the tiles it produces. In fact, the Keele investment led to Marley becoming the first manufacturer to adopt environmental profiling. Today the company’s entire clay plain tile range can achieve an A+ rating under the BRE’s environmental assessment schemes and independent carbon certification, with a carbon footprint rating of just 27.0 kgCO2e / m2 (based on 100mm gauge for an Acme single camber clay plain tile).

Sarah Jackson adds: “Marley has always been at the forefront of sustainability within our industry and being able to offer the maximum credits under responsible sourcing scheme not only positively sets us apart from other manufacturers within our industry but also gives our products a tangible benefit in accordance with BREEAM and the Code for Sustainable Homes.”

Using products that are responsibly sourced allows specifiers to deliver projects that achieve a higher number of credits within the BREEAM and the Code for Sustainable Homes certification schemes. The three credits gained through the use of Marley’s A+ rated clay tiles is now enhanced with the additional three credits available for demonstrating a ‘very good’ rating for responsible sourcing.

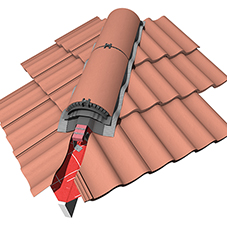

Marley’s investment in clay tile manufacturing means it has the largest clay plain tile production capacity in the UK. This includes the evolution of the widest range of colours and an unrivalled choice of fittings and accessories.

Clay Tiles From A Very Good Responsible Source

| T | (01283) 722588 |

|---|---|

| E | info@marley.co.uk |

| W | Visit Marley's website |

| Lichfield Rd, Branston, Burton-on-Trent, Staffs, DE14 3HD |

Products by this Company

Categories

Roof tiles Roof tiles, clay