At Stone Cladding Systems they are passionate about the reduction in Embodied and Operational Carbon and so too are our partners Hilti GB. Here we look at a blog first published on their website

Introduction

Whether you are a specifier, contractor, or supplier to the building sector; sustainability is a topic that is increasingly top of mind, especially considering that the build environment contributes to around 40% of global CO2 emissions.[1] At Stone Cladding Systems & Hilti, we share global climate ambitions to limit global warming to 1,5°C and Hilti have committed to the Science Based Targets Initiative working towards net zero emissions by 2050. Our aim is to become our customers’ best partner for sustainability.

To reach global climate goals in the construction industry, it is important to understand the difference between embodied and operational carbon and its contribution to total emissions. Operational carbon is the result of maintaining and using a building (e.g. heating, cooling, ventilation, lighting) during its lifetime. Embodied carbon is the “upfront carbon” emitted during the extraction, production, and transport of materials. Around 13% of the built environment emissions come from embodied carbon. Until recently, the focus within the construction industry was on the operational performance of a building – how much and what type of insulation and energy is needed for heating and/or cooling (operational carbon). As buildings are becoming more energy efficient, there has been increasing attention on the embodied carbon of materials in recent years.

The Natural Stone Façade, as the interface between the inside and outside of the building is impacting both parts of total emissions. Ventilated façade systems with different thermal performances impact the operational emissions of a building, while the material selection of the substructure impacts the embodied carbon footprint. Their selection determines the contribution to building total carbon emissions and the ratio between embodied and operational emissions during the building’s lifespan. As improving thermal efficiency often comes with adding material for insulation, resulting in increased embodied carbon, it is crucial to understand how embodied and operational carbon interact.

Embodied carbon and Environmental Product Declarations (EPDs)

Embodied carbon is the CO2 embedded into the building once established – also sometimes referred to as “upfront carbon”. The Façade accounts for 10-20% of a building’s embodied carbon footprint of a building[2]. Natural Stone, especially that sourced locally, is very low in embodied Carbon whilst Aluminium is a significant source of CO2 with a footprint of around 8 kg CO2e per kg material. To be able to transparently declare the carbon emissions and enable product comparison, the EPDs are developed. At Stone Cladding Systems & Hilti, we are intensively creating the EPDs for our portfolio based on different stones on the Aztec System with the Hilti Rails and brackets.

An EPD is a standardised and verified document reporting a product’s environmental impacts. The environmental data is created using a holistic life-cycle assessment based on EN15804+A2 standard and is verified by a third-party expert. An essential information in an EPD is the product’s carbon footprint – called the Global Warming Potential (GWP).

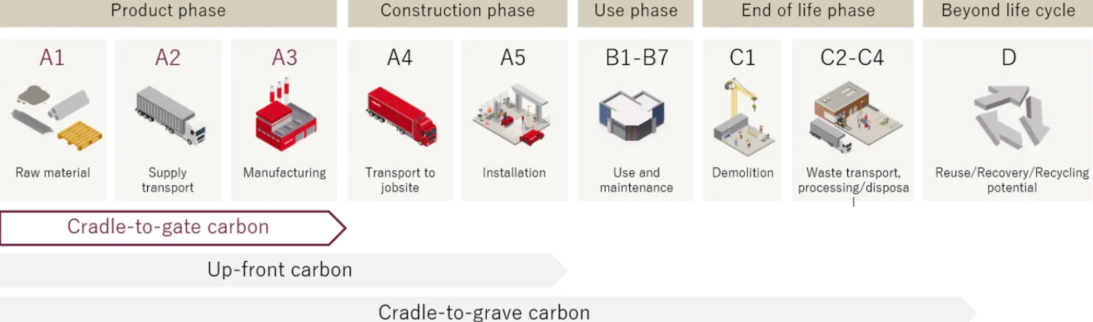

Often one would search for carbon emissions information in an EPD to assess the impact of using a product in a construction project. As indicated in the figure above, A1 to A3 stages play a crucial role in assessing product embodied carbon since it takes up a significant majority of the total CO2 emissions. A1 to A3 stages encompass the utilisation of all materials, products, and energy, as well as waste processing up to the end-of-waste state or disposal of final residues during the product stage. This reflects the CO2 emissions until the product is out of the factory gate, therefore is referred to as “cradle-to-gate” assessment. The lower the CO2 value (GWP) in the A1-A3 stage, the better for the climate.

For further information please contact the team

Embodied and Operational Carbon - Stone Cladding Systems

| T | 01335 361000 |

|---|---|

| E | sales@scs-stone.co.uk |

| W | Visit Stone Cladding Systems Ltd's website |

| Ednaston Business Park Ashbourne DE6 3FA |

Categories

Natural stone