In the heart of Buxted Construction's bustling storage and distribution yard, a transformative project unfolded: the comprehensive replacement of drainage systems. Faced with the challenge of managing substantial volumes of silt and water accumulation, their choice was clear: Heavy Duty Channel systems, meticulously designed to meet the demands of such rigorous environments.

Selected through one of their trusted distributors, their solution seamlessly integrated into Buxted Construction's operations, reflecting their commitment to quality and reliability. Notably, this project holds personal significance as Buxted Construction entrusted BG-FILCOTEN for their own premises, further validating the efficacy and trustworthiness of their products.

People involved

BG Project manager: Lilly Beal

Construction company: Buxted Construction Ltd, West Kingsdown, Kent

Distributor: Castings Drainage Supplies, Bracknell, Berkshire

BG-Products used in this project

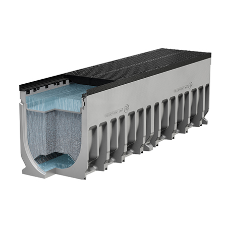

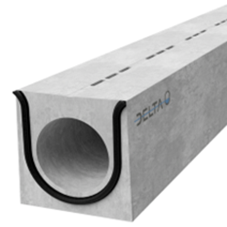

Channel drain type:

BG-FILCOTEN pro G NW300, Channel 0-0

Grating type:

NW300 F900 Ductile Iron Slotted Grate

Total linear meters used:

54

“Technology”

Minimal Weight

• FILCOTEN® HPC enables lightweight construction

• Quick and easy to place

• Dimensionally stable, robust concrete elements

Maximum Durability

• Unsurpassed stability and durability

• Exceptional pressure resistance, well above the requirements in EN 1433

Resistant to extreme temperatures and UV light

• Maximum resistance to frost and de-icing salt

• UV resistant

Fireproof

• Non-combustible construction material – Class A1

• No harmful smoke development

Perfect hold in the concrete bed

• Ideal coefficient of expansion, identical to that of the surrounding concrete

High drainage performance

• Low water collection and penetration

• Smooth channel surface for high drainage performance and optimal self-cleaning effect

Sustainability

Verified LCA (Life Cycle Assessment)

• Greater ecological transparency under ISO 14040/14044 and EN 15804

• Ideal for sustainable construction projects

Sustainable production

• Manufactured with 100% green power

• Resource-efficient manufacturing process

Exceptional resource-efficiency

• 100% recyclable, certified

• Quality A class U-A (Certified by the Building Research Institute of Salzburg (bvfs))

Enhancing Efficiency: BG-FILCOTEN's Heavy Duty Drainage Solution at Buxted Construction

| T | 01424 817050 |

|---|---|

| E | sales.uk@bg-graspointner.com |

| W | Visit BG-Graspointner UK Ltd's website |

| Magneta Building, 2 Brookhill Way, Banbury, Oxon, OX16 3ED |

Products by this Company