In the construction industry, sustainability is not just a buzzword; it’s a necessity. As climate change and environmental degradation continue to threaten the planet, companies across all sectors are reevaluating their practices to reduce their ecological footprint. At Firma, an innovative masonry support design and manufacturer, we are committed to integrating environmental sustainability into every aspect of operations. Here’s how they're doing it and why it matters.

Understanding Environmental Sustainability in Construction

Environmental sustainability in construction involves practices that minimize the negative impact on the environment. This includes reducing waste, lowering greenhouse gas emissions, conserving natural resources, and ensuring that building materials and processes are eco-friendly. For a masonry support specialist like Firma, this translates into several key areas of focus:

1. Sustainable Materials: Choosing materials that are either recycled, recyclable, or have a lower environmental impact. They use ISO14001 accredited material suppliers, and ask for evidence of a sustainable supply chain, as part of their supply chain vetting process.

2. Efficient Processes: Implementing processes that reduce waste and energy consumption. Improvements in efficiencies, such as bringing warehouses under the same roof, means they can prevent duplication of deliveries, and plant. Their cutting-edge in-house nitrogen generator is another example of this, that means they can cut down on transport miles and prevent wastage, by creating their own sustainable energy.

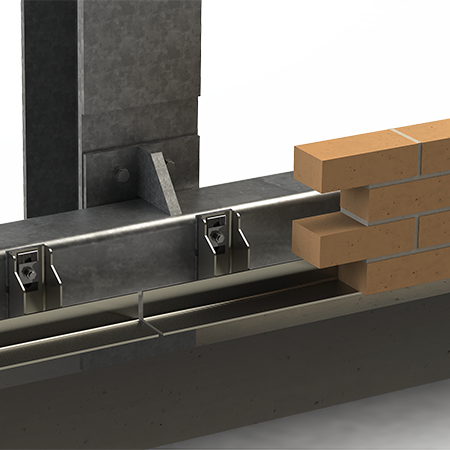

3. Innovation and Design: Developing new solutions that enhance the sustainability of buildings are vital. There are many ways this can be done such as through higher spec thermal shims to prevent thermal transfer or value engineering out unnecessary brackets, through creative designs.

Sustainable Materials: Building a Greener Future

One of the most significant ways Firma contributes to sustainability is through their selection of materials. Traditional masonry materials can be resource-intensive to produce. However, advances in material science have provided alternatives that are both durable and eco-friendly.

Recycled Materials: They prioritize the use of recycled materials wherever possible. This not only reduces the demand for virgin resources but also diverts waste from landfills. All their wastage is recycled by accredited waste carriers.

Sustainable Sourcing: All our materials are sourced from suppliers who follow sustainable practices, ensuring that our supply chain supports environmental responsibility.

Efficient Processes: Reducing Waste and Energy Use

Efficiency is at the heart of sustainability. At Firma, they've adopted several measures to ensure our processes are as efficient as possible.

Lean Construction Principles: By following lean construction principles, they minimize waste and improve resource efficiency. This involves meticulous planning and the use of technologies like our business central ERP system to optimize our projects workflow, and ensure things are done right first time.

Energy-Efficient Machinery: Our commitment extends to the equipment they use. They invest in energy-efficient machinery and vehicles to reduce our overall energy consumption and greenhouse gas emissions. They have an electric forklift, and cutting-edge machinery, which is much more efficient than older machines.

Waste Prevention: All our fixings are sent to site in re-usable buckets, with lids. Why? Because this prevents fixings going missing, and the fixing container just being thrown away afterwards.

Innovation and Design: Pioneering Sustainable Solutions

Innovation is crucial to advancing sustainability in masonry support. Firma is dedicated to developing and implementing new technologies and designs that not only meet but exceed sustainability standards.

Passive Design Strategies: By incorporating passive house design strategies, they help buildings achieve greater energy efficiency. They encourage our designers to study passive house principles and take note of this when designing masonry support.

Less metal, less emissions: They are continually looking for ways to challenge the norms and reduce the amount of material used in masonry support bracket. This can be achieved through structural innovation, and seeing what is surplus to requirements, without harming structural integrity. As this offers cost savings, it makes sustainable choices attractive to the contractor.

A Firma Future:

At Firma, they believe that every company has a role to play in fostering a sustainable future. They can make a true difference, especially being in construction, as they can reduce thermal transfer and material usage. Our dedication to environmental sustainability is reflected in our practices, our products, and our people. By continuing to innovate and strive for excellence in sustainability, they are not only enhancing the built environment but also contributing to a healthier planet for all.

Join us on our journey of building for a Firma future.

Environmental Sustainability in Masonry Support – building a Firma Future

| T | (01603) 722330 |

|---|---|

| F | (01603) 722777 |

| E | sales@firma.co.uk |

| W | Visit FIRMA's website |

| 22 Bidwell Road, Rackheath Ind Est, Norwich, Norfolk, NR13 6PT |

Categories

Building materials

-comp212644.jpg)