A range of high performing acoustic products and fully tested systems from Hush Acoustics is helping architects and developers avoid potentially costly sound transmission issues in separating floors when building with steel frame systems (SFS) and light gauge steel framing (LGSF).

As the popularity of steel frame construction has grown in the UK in recent decades, Hush Acoustics has experienced an increase in requests for technical guidance in relation to minimising sound transmission through SFS and LGSF wall, floor and roof sections supplied in modular form. In particular, it is SFS floor cassettes that represent the bulk of these enquiries, largely due to how the steel sections can make meeting impact and airborne sound reduction levels challenging.

Within the Hush portfolio are a number of products which are ideally suited to reducing the risk of sound issues in modular floor cassettes. The range provides products for the voids that are formed within the steel frame structure and the ceiling below to make it more insulated against airborne sound, as well as floor treatments to reduce impact noise.

Choosing Hush Slab 100 as the rigid insulation between the joists can improve acoustic performance versus other products. This is due to its mineral wool composition that is optimised to disrupt and absorb soundwaves generated from everyday activities such as speaking or playing music.

Joist infills, however, of any kind may not be sufficient in isolation, depending on the acoustic targets. This is why using an acoustic system, including one of Hush Acoustics’ fully tested systems, can pay dividends with steel frame floor cassettes as they offer an upgrade to all three parts of the modular floor cassette – at floor level, within the floor structure and at ceiling level.

The key to enhancing the acoustic performance of a steel floor system is to add mass and decouple the floor deck and ceiling from the structure. There are a number of ways this could be achieved, but choosing a fully developed and tested system has the advantage of being almost an ‘off the shelf’ solution.

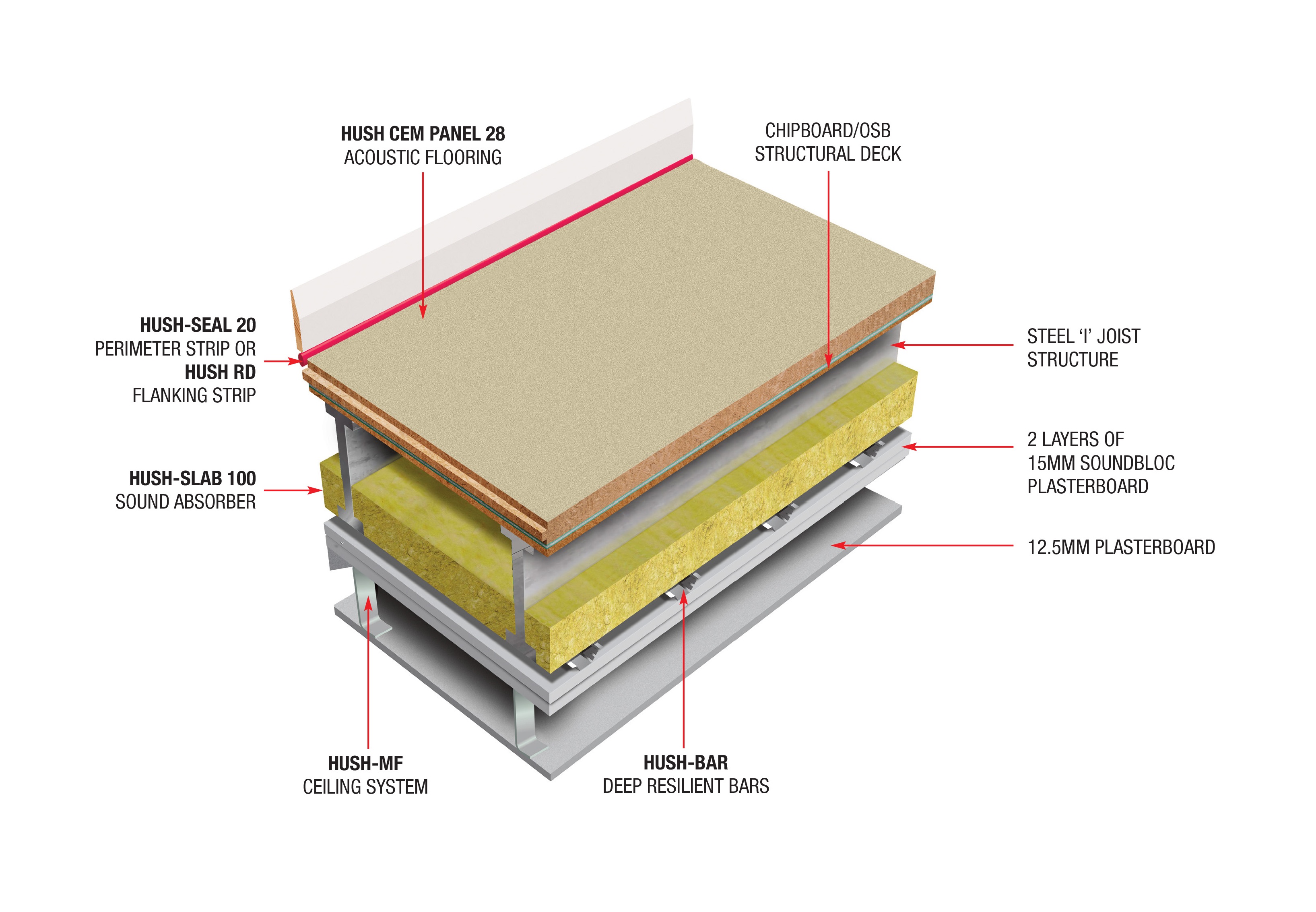

One Hush system that is ideally suited to SFS floor cassettes is the HD1059 Hush Cem Panel 28 Steel Frame System. This features an acoustic floating floor above the deck, joist infills and a suspended ceiling below, which is created by installing an MF (metal frame) system.

Key to its ability to provide a high performance acoustic solution are Hush Panel Cem 28 panels which are laid over the existing plywood or OSB deck common in SFS floor cassettes to form a floating floor. The cement particleboard composition of Hush Panel Cem 28, rather than plywood that is used for standard acoustic floor panels, adds density to the overall steel floor structure to help with airborne sound reduction, whilst decoupling the floor surface from the structure via a resilient layer formed of Hush Felt.

Below the joists, the system uses Hush Bar Deep resilient bars to decouple the ceiling from the structure and prevent direct sound paths from the steel C sections. Twin layers of 15mm Gyproc SoundBloc plasterboard attach to the resilient bars and the MF suspended ceiling system is then attached, creating an additional void, with a standard 12.5mm plasterboard fixed to this to complete the ceiling.

Such is the effectiveness of the HD1059 Hush Cem Panel 28 Steel Frame System that it can ensure SFS floor cassettes not only comply with, but go beyond the minimum standards set by the Building Regulations.

Hush Acoustics’ technical team works with architects, developers and contractors to advise on which system is best suited to the needs of the project. They can also develop bespoke acoustic treatments for steel framing building projects which may be more appropriate to overcome specific design issues.

Contact the team today for assistance on 0114 352 0729 or via the website: www.hushacoustics.co.uk.

Hush Acoustics leads the way with sound reduction solutions for SFS floor cassettes

Image Gallery

| T | 0151 933 2026 |

|---|---|

| E | info@hushacoustics.co.uk |

| W | Visit Hush Acoustics' website |

| Unit 2, Tinsley Industrial Estate, Shepcote Way, Sheffield, S9 1TH |

Products by this Company