Insulating clamps and fittings in heating and cooling systems is just as important as the pipework itself. Here, Anthony Barnett, Technical Marketing Manager at Armacell, looks at the reasons why.

In central heating services the purpose of insulating pipework and fittings is to minimise heat loss, and heating and plumbing pipes are insulated as a matter of course according to the building regulations. However, pipe supports are often overlooked and can remain un-insulated or incorrectly insulated. Pipe brackets that are uninsulated can cause significant heat losses in a system.

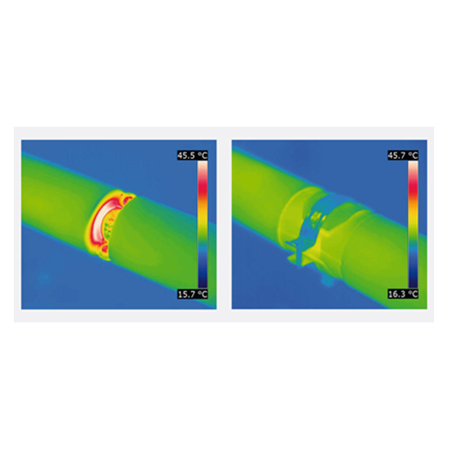

The consequences of pipe brackets not being insulated can be seen in figure 1 using a thermal imaging camera. The extent of this loss of energy can be significant, with thermal heat flow calcula¬tions for a 60°C hot water pipe in continual use, showing a heat loss of 0.06 w/k per bracket (on a 26.9mm diameter copper pipe with a 27mm insulation thickness). This can have a major effect in total energy costs of running a building, especially where a large number of supports are used.

Insulating pipe brackets on cold services

The direct fixing of cold services pipework to their mounting brackets acts as a bridge for thermal gains from surrounding warmer ambient air. Since these un-insulated supports on chilled water and refrigeration pipework fall below the dew point, the cold air surrounding the brackets is less able to hold water, causing a difference in partial vapour pressure. In these conditions, moisture is continually drawn to the cold brackets, diffusing and condensing into the adjoining insulation material. If the condensation spreads through the insulation system thermal efficiency is lost and corrosion and consequential secondary damage will result.

Pipes in refrigeration and air-conditioning applications must therefore always be isolated from their mounting element with an adequate closed-cell insulation thickness, taking into account the line temperature, pipe size, ambient temperature and relative humidity conditions.

Using non-compatible clamps on cold installations

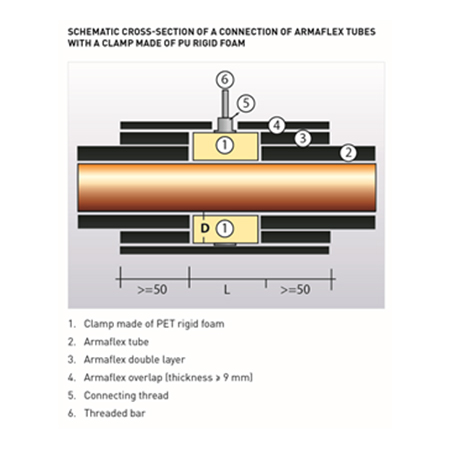

Often PUR/PIR clamps are used to mount pipes. Extensive tests on the reliability of bonds between elastomeric insulation materials and this type of clamp have shown that it is not always effective. In fact, the connection can be a weak point, allowing condensation to form and, in some cases, ice as shown on Figure 2.

A reliable connection between the clamps and an elastomeric insulation material can only be achieved by encasing the PUR/PIR clamp with insulation as shown in Figure 3.

Insulated pipe supports as system components

Alternatively pipes and pipe brackets in cold applications can be thermally isolated from each other by installing pre-fabricated elastomeric insulation supports such as the Armafix range. Compatible and available for all Armaflex tubes and sheet types, this ensures that the key technical requirements for insulation of brackets on cold installations are covered with a low thermal conductivity and high µ-value material (resistance to water vapour transmission).

Integrated load-bearing segments prevent the insulation material being compressed and are themselves protected against moisture absorption with fully-glued vapour barriers. In addition outer metal shells serve to distribute the load. Similar, easy to install, system solutions are also available for air-conditioning ducts (traverses).

Summary

Thermally isolating the pipe from its fixing is the best way of ensuring optimum insulation performance. A complete insulation system approach, where the insulation material and insulated pipe supports are from a single source, offers greater compatibility in terms of condensation control, fire behaviour, energy saving and ease of installation. By doing this specifiers and installers can ensure the efficiency of the system whilst providing their customer with a long term low maintenance system.

View AF/ArmaFlex Class O Product Entry