Scaling the Italian-Swiss border at almost 15,000 feet, the Matterhorn is both one of the most recognisable of the Alpine peaks and one of the most challenging. For mountaineers, the favoured access route is along the Hörnli Ridge, to the south-west of Zermatt. Serving as a base camp for over 100 years and situated at just over 10,000 feet, near the foot of the ridge, are the Hörnlihütte (Hörnli Lodge) and Hotel Belvédère. The two were merged in 1987 and have undergone various changes over the years, but the most recent work was ambitious and challenging. It involved replacing the Hörnli Lodge with a new state-of-the art structure, combined with extensive renovation of the Belvedere.

Minimising any heat transference was critical

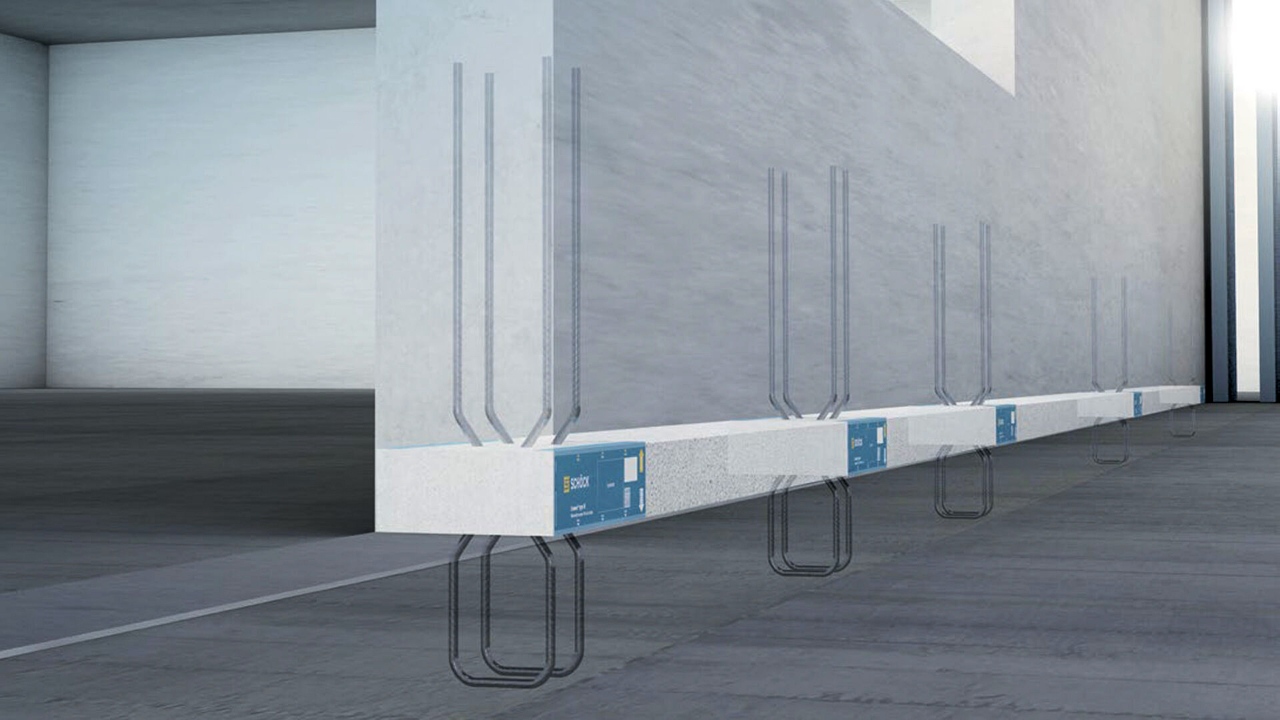

As the building is constructed on a poured in-situ concrete slab, one particularly critical area was minimising any heat transference between the buildings and the slab. With reinforced concrete construction, linear thermal bridges at the wall connection to the floor, or floor slab, have always been a major problem. Schöck, the well experienced in the development of structural thermal breaks for balconies and other cantilever constructions, has now innovatively applied its Isokorb expertise to reinforced concrete wall and support. The result is the Sconnex type W, an application-friendly, dedicated solution that contributes to a permanently sustainable building concept.

An extremely harsh environment

Building in the High Alps is challenging. The project involved extremely steep ground, very narrow site conditions and a tight schedule for the outside work, given the seasonal Alpine weather conditions. In addition, the only access to site is by means of a narrow, steep path and the construction teams and all materials – including the concrete – had to be flown in using helicopters. It is a harsh environment and the Sconnex type W from Schöck certainly meets the challenge.

Highest energy standards

It offers enormous energy-saving potential and by reducing the heat transfer coefficient helps buildings meet the highest energy standards – without requiring flanking insulation – which is less energy efficient. If under-slab insulation is employed, heat loss is reduced by up to 59%, but if above-slab insulation is used, heat loss is reduced by up to 80%.

Serious energy loss in the area of the thermal bridge also means that the temperature of the interior surface is lower and if the area becomes too cold it can lead to condensation. Over time, mould is likely to form, potentially damaging the building structure and even posing a health risk to the inhabitants. The outstanding insulation performance of the Sconnex type W is combined with an excellent load-bearing capacity, which transmits very high pressure, tensile and shear forces in the longitudinal and transverse direction. This is made possible by the use of a pressure buffer consisting of ultra-high performance fibre reinforced concrete. A material which achieves compressive strength levels in excess of 175 N/mm2, but with extremely good flexural strength as well.

Latest innovative Schöck solution reaches new heights

| T | (01865) 290 890 |

|---|---|

| F | (01865) 290899 |

| E | design-uk@schoeck.com |

| W | Visit Schöck's website |

| Staniford House, 4 Wedgwood Road, Bicester, Oxfordshire, OX26 4UL |

resized-comp212922.jpg)