“We are finishing an office fit-out project for a major client. Everyone is happy until the client suddenly asks: ‘and in what way is this design green? Because we’d like to tell people about that’.” What can you do to avoid finding yourself in a situation like this? How to design actually greener office interiors with acoustics in mind?

While many companies include climate neutrality in their strategic goals, stories like this still do happen. Certain solutions, such as maximizing access to daylight and reusing furniture, have long been used in office settings, fitting perfectly into the green design agenda. What is often missing, however, is the cornerstone of the green office concept: making informed choices about finishing materials and equipment. This results in designs that have a bigger environmental footprint than they would otherwise. We’ll show you how to avoid this.

Tip 1: Joint decision-making as early as possible

The approach that sees the environmental impact of design as top priority is a topic to be discussed as soon as the architect and the investor first meet. It is necessary to identify what such an approach involves, how it is put into practice, and how it is communicated to all stakeholders.

Tip 2: Be specific

Determine as early as possible the environmental parameters that will drive product selection. Most often those include the carbon footprint across the whole life cycle, the share of recycled raw materials, or the practical recyclability of the material. What also matters is the class that specifies the level of emissions of volatile organic compounds into ambient air, which has an impact both on the environment and on the health of interior users.

Tip 3: Demand evidence

When choosing products, ask for documentation to support their environmental performance. The most common document is the Environmental Product Declaration (EPD), verified independently by a third party. It features information on the carbon footprint, share of raw material recycled, VOC emissions class etc. The level of VOC emissions can be determined using the Finnish M1 label or the French VOC classification.

It makes profound sense to ask for an EPD as it allows for drawing comparisons and ultimately facilitates data-driven informed decision-making. Yet another advantage is that this works as an incentive for manufacturers to test their products. Test results, in turn, inform the necessary changes in production technologies, the choice of suppliers or distribution methods.

Tip 4: Watch out for catches

When comparing environmental parameters, pay attention to whether the tests concern the entire life cycle, a specific single product type, or a complete solution. It is worth finding out where the solutions were manufactured.

Tip 5: Consider product durability, timelessness, and the actual possibility to dismantle it

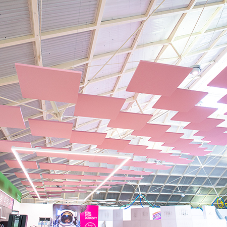

Products that are easy to clean, do not disintegrate or deform over time will last longer. They may also be moved to be used elsewhere. We have clients who have been using the same Ecophon Solo™ free-hanging acoustic panels in their third location. And there are those that have been rearranging Ecophon Focus™ modular ceilings to suit a new workplace layout. Moving Ecophon Akusto™ wall panels to new locations is now a standard practice. This can all be done if the material is durable, easy to clean and has a universal, timeless design.

Tip 6: Don't give up, but choose consciously

Don't give up on anything that has a significant impact on the well-being of users and the functionality of the space. However, choose what has less impact on the environment. Good acoustics, lighting, high air quality – all these matter. Companies stay longer in thoughtfully designed, healthy office interiors. And this is best for the environment too.

Why are we writing about this?

Ecophon believe in their huge responsibility as manufacturers because designers rely on what they provide! Ecophon must shoulder this burden and really act on it – while providing credible evidence that we do. Ecophon have been working for many years to reduce their environmental footprint. As a result, their acoustic ceilings and wall panels have a lower carbon footprint than other solutions offered on the market, as well as featuring a consistently high share of recycled raw materials.

In the interest of transparency and easy access to information, Ecophon provide all interested parties with documentation on our manufacturing standards and with their reliable Environmental Product Declarations – for each product individually and for their entire life cycles. And they don't stop there, as the process of reducing our environmental impact involves ongoing work and learning.

Less waste office design – hands-on tips

| T | 01256 855208 |

|---|---|

| E | technical@ecophon.co.uk |

| W | Visit Saint-Gobain Ecophon's website |

| Saint-Gobain Ecophon, Old Brick Kiln, Monk Sherborne, Tadley, Hampshire, RG26 5PP |