Ruby coloured fibre cement Natura from Marley has created the striking visual centrepiece of the £17.5m rebuild and refurbishment of Abraham Moss High School in Manchester.

Natura was specified by Ellis Williams Architects for the main four storey steel frame building that has a cantilevered section over the entrance area.

Careful selection of lightweight, strong building components was therefore critical for creating this cantilevered design, along with contributing to the strict environmental aspects of the project.

New build elements of Abraham Moss High School, which make up 60% of the development, are expected to achieve a BREEAM Very Good rating. Marley fibre cement cladding panels contributed to this because they can achieve an A+ rating as defined in the BRE Green Guide to Specification based on generic rating for autoclaved fibre cement single sheet - (Element Ref: 80623042, 806230422, 806230447, 806230450).

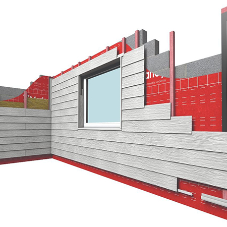

Fibre cement Natura was used as rainscreen cladding on the new build elements and as an overclad solution on existing buildings at the school where walls had been exposed as a result of removing some bridge links between first and second floor levels.

Abraham Moss High School is part of Manchester’s Building Schools for the Future and Academies Programme, which has a £500m investment to rebuild or refurbish all the city’s high schools.

“The fibre cement rainscreen cladding from Marley allowed us to create a visually stunning building that will provide the school with a long term low maintenance solution,” said Robert Plant, Associate at Ellis Williams Architects. “The lightweight nature of fibre cement rainscreen cladding gave us greater flexibility in creating the cantilevered design.”

He added: “Fibre cement was a versatile solution that we could use for both the new build and smaller overclad sections, allowing us to create a visual link between the old and new.”

Walls at Abraham Moss High School were constructed using a lightweight steel frame construction. This was sheathed externally with cement particle board.

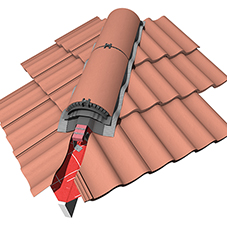

The rainscreen system consisting of a 125mm thickness of dense mineral wool insulation faced with a breather membrane layer and installed within the bracket zone for the panel support angles, leaving a ventilated rainscreen cavity behind the Natura panels. The wall was designed to achieve a U-value of 0.34 W/m²K.

A secret fix method was used to mount the fibre cement Natura panels to create a smooth, shear facade free of any visible fixings. The main contractor on the project was GB Building Solutions Ltd.

Natura at Abraham Moss High School, Manchester.

| T | (01283) 722588 |

|---|---|

| E | info@marley.co.uk |

| W | Visit Marley's website |

| Lichfield Rd, Branston, Burton-on-Trent, Staffs, DE14 3HD |

Products by this Company

Categories

Rainscreen cladding