Minimising thermal bridging at the wall connection to the floor, or floor slab, is an ongoing problem with reinforced concrete construction. However, a dedicated new solution – the Sconnex type W – has been developed by Schöck and is being installed in what is currently the largest Passivhaus accredited social housing scheme in the North of England. The ‘Greenhaus’ nine-storey development of 96 affordable homes in Chapel Street, Salford, is part of the 50-acre Salford Central regeneration and the result of a collaboration between The English Cities Fund (ECF) – a national development partnership between Muse, Legal & General and Homes England – contractor Eric Wright Construction and Salix Homes. The scheme focuses on sustainability and is designed to reduce the energy consumption of the building. With Passivhaus, energy savings can be as much as 90% compared with the average building stock and more than 75% compared to average new builds.

Thermal losses are greatly reduced

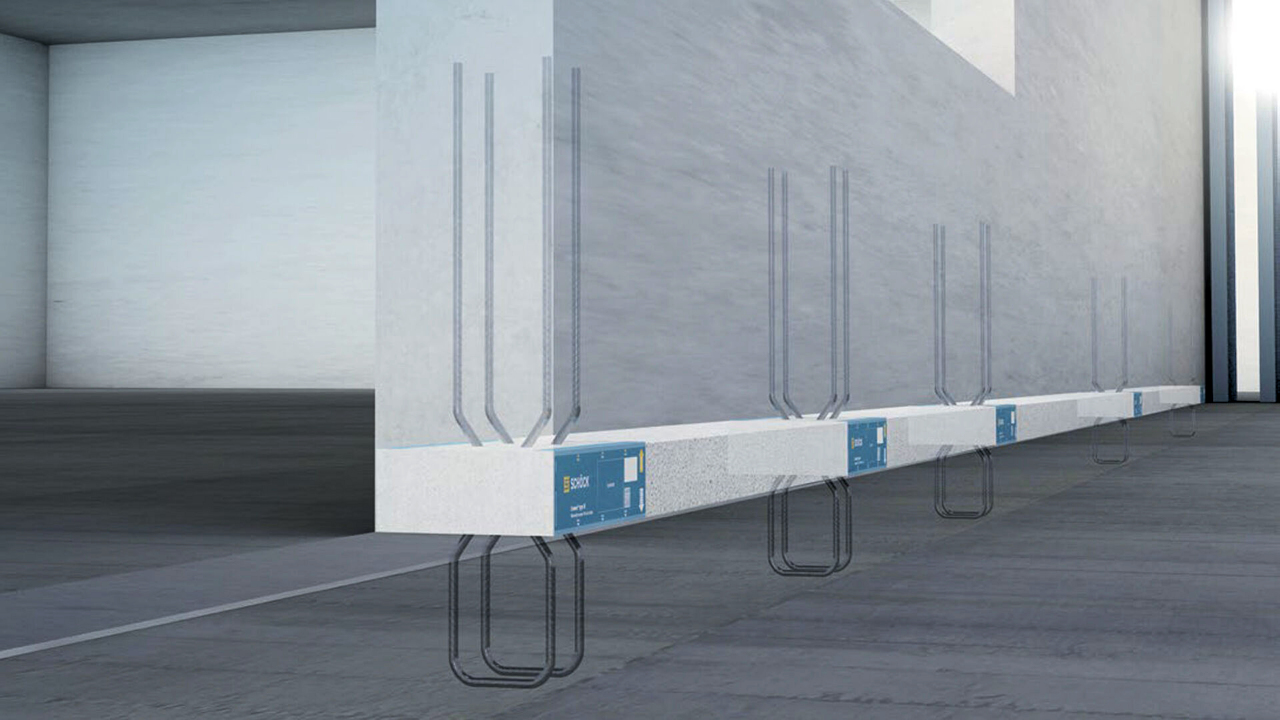

The unique Schöck Sconnex type W makes a major contribution to achieving this initiative and is a product is based on derivative technology from Schöck. Sconnex utilises the company’s long-standing expertise in structural thermal breaks for balconies and other cantilever constructions and applies it to reinforced concrete wall and support applications. By installing the Sconnex product in Chapel Street, thermal losses are greatly reduced and the surface temperature in the rooms increases to considerably more than the critical dew point temperature. Heating costs are lower, a pleasant room climate is created and the linear thermal transmittance (Psi) of the connected reinforced concrete wall is reduced by as much as 80%. This outstanding insulation performance is combined with an excellent load-bearing capacity. It transmits very high pressure, tensile and shear forces, in the longitudinal and transverse direction, made possible by the use of a pressure buffer consisting of ultra-high performance fibre reinforced concrete. Compressive strength levels in excess of 175 N/mm2 are achieved, with extremely good flexural strength. A further important benefit is the significant cost reduction involved when compared to installing insulation beneath the floor slab.

Eric Wright and Salix have key roles

Greenhaus forms part of ECF’s wider £1bn, 50-acre, Salford Central masterplan transforming former surface car parks and derelict buildings into a vibrant and diverse community. John Hartnett, managing director at Eric Wright Construction, comments: “We are proud to be supporting not only a green future for Salford, with the delivery of high efficiency buildings built to Passivhaus standards, but also supporting Eric Wright’s own journey to net zero carbon. These new homes will deliver valuable social housing in partnership with Salix Homes.“

Sue Sutton, chief executive at Salix Homes, also adds: “Chapel Street enjoys an incredibly rich history and the innovative Greenhaus development marks the next exciting chapter for this historic part of Salford. At a time when affordable housing is in such short supply, we’re very proud to work alongside our partners to deliver these high quality, sustainable, eco-homes of the future, and we look forward to seeing this ambitious development take shape on the Salford skyline.”

For further information on the new Sconnex type W product contact Schöck on 01865 290 890; or download the brochure at www.schoeck.com

New Schöck Sconnex for major Passivhaus social housing scheme

| T | (01865) 290 890 |

|---|---|

| F | (01865) 290899 |

| E | design-uk@schoeck.com |

| W | Visit Schöck's website |

| Staniford House, 4 Wedgwood Road, Bicester, Oxfordshire, OX26 4UL |

resized-comp212922.jpg)