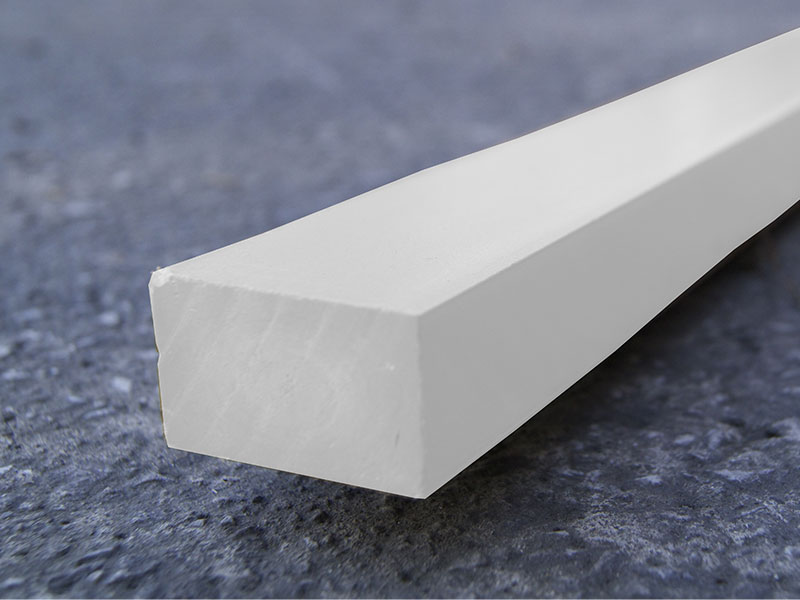

Recycled plastic construction involves using materials made from post-consumer plastic waste. This plastic is processed, shredded, and extruded or moulded into products like beams, battens, rafter tails and gallows brackets. These materials not only have a lower carbon footprint compared to traditional building materials but also offer enhanced durability and resistance to pests and moisture.

Kedel Ltd, a Burnley based company manufacture a range of recycled plastic products that are in demand by house builders, contractors and end users alike.

Advantages of Using Recycled Plastic in Home Building

1. Sustainability: Incorporating recycled plastics reduces reliance on virgin materials and minimises environmental impact.

2. Durability: Recycled plastic materials are resistant to rot, corrosion, and insects than conventional wood and metal, leading to longer-lasting structures with reduced maintenance costs.

3. Cost-Effectiveness: While the initial investment might be higher than traditional materials, the long-term savings from reduced maintenance makes recycled plastic an economical choice.

The integration of recycled plastic into home building represents a significant step toward a more sustainable future. By choosing eco-friendly materials, home builders can play a vital role in reducing plastic waste while enjoying the benefits of durable, energy-efficient homes. As the construction industry continues to innovate, recycled plastic may become a cornerstone of sustainable building practices, paving the way for a greener planet.

In a world where every choice matters, opting for homes built using recycled plastic is not just a trend—it's a commitment to a sustainable future.

Recycled Plastic – Uses in Construction

| T | (01282) 861325 |

|---|---|

| E | sales@kedel.co.uk |

| W | Visit Kedel Limited's website |

| Oswald Street, Burnley, Lancashire, BB12 0BY |

Products by this Company

Categories

Copings and cappings, plastic