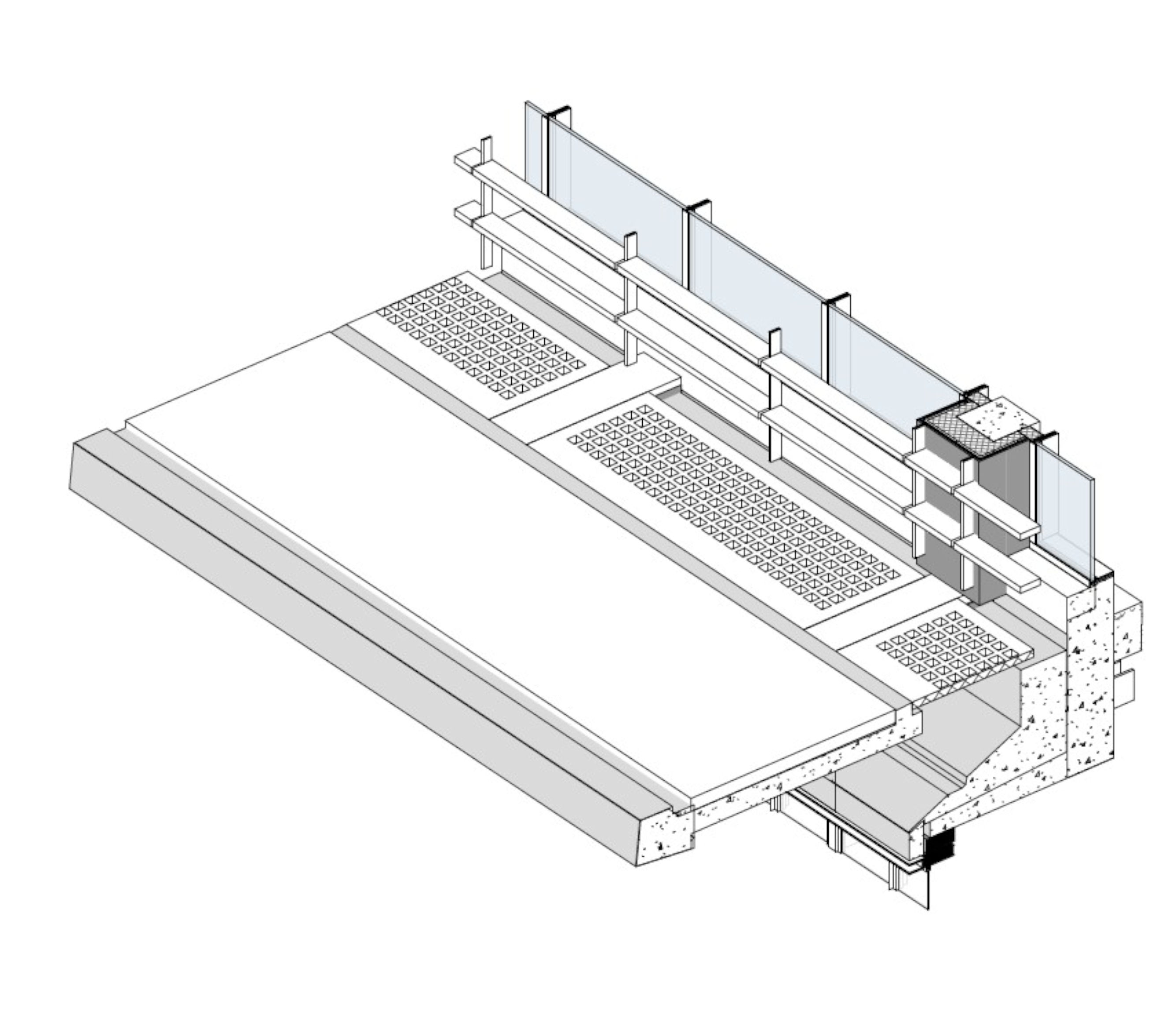

Enhanced by the saw-tooth roof design, reflecting the industrial heritage of the site, Sadler’s Wells East will join the cultural heritage of the East Bank development at Stratford, when the new dance theatre opens at London’s Queen Elizabeth Olympic Park in 2024. The design has many distinctive features, but a major focal point is the cantilevered canopy. This runs the length of the frontage and is designed to carry a precast green roof – which presented a number of design and structural challenges.

A bespoke solution from Schöck

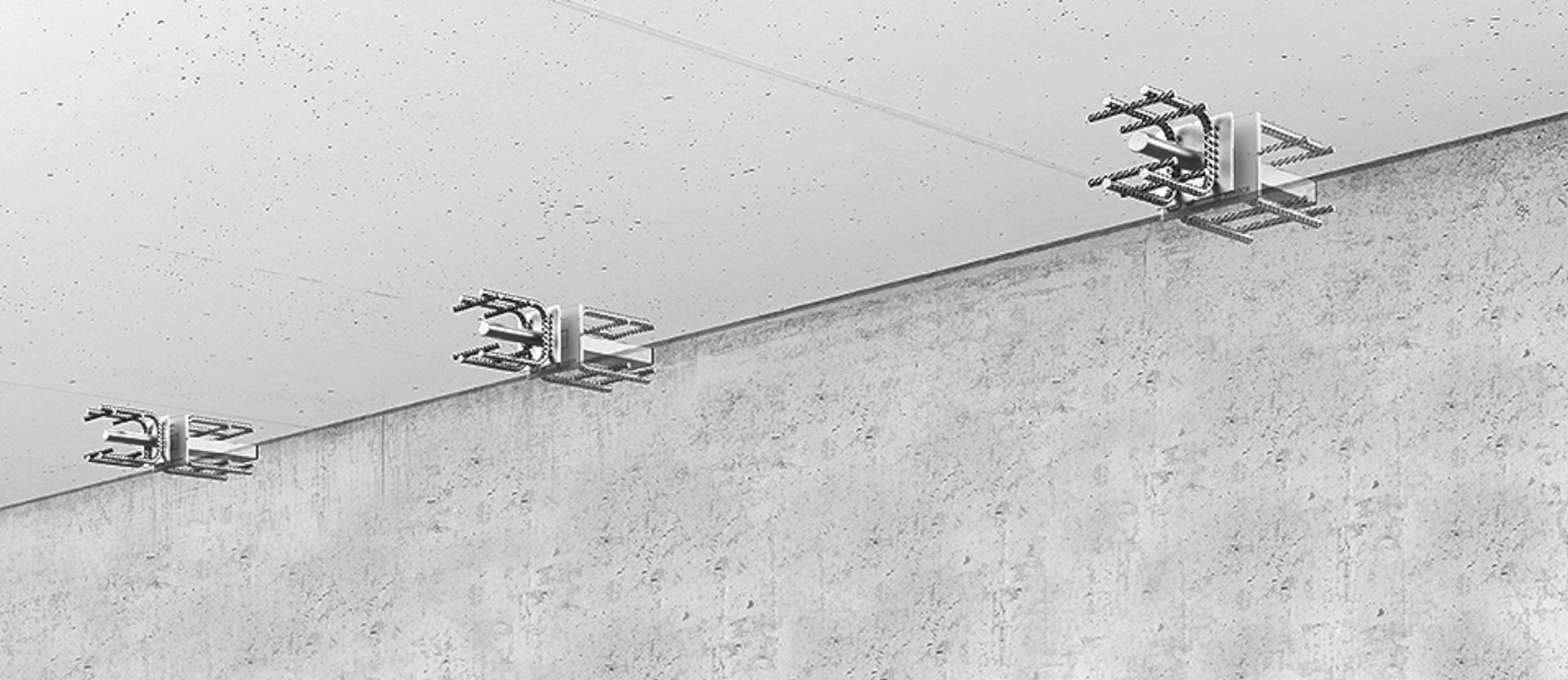

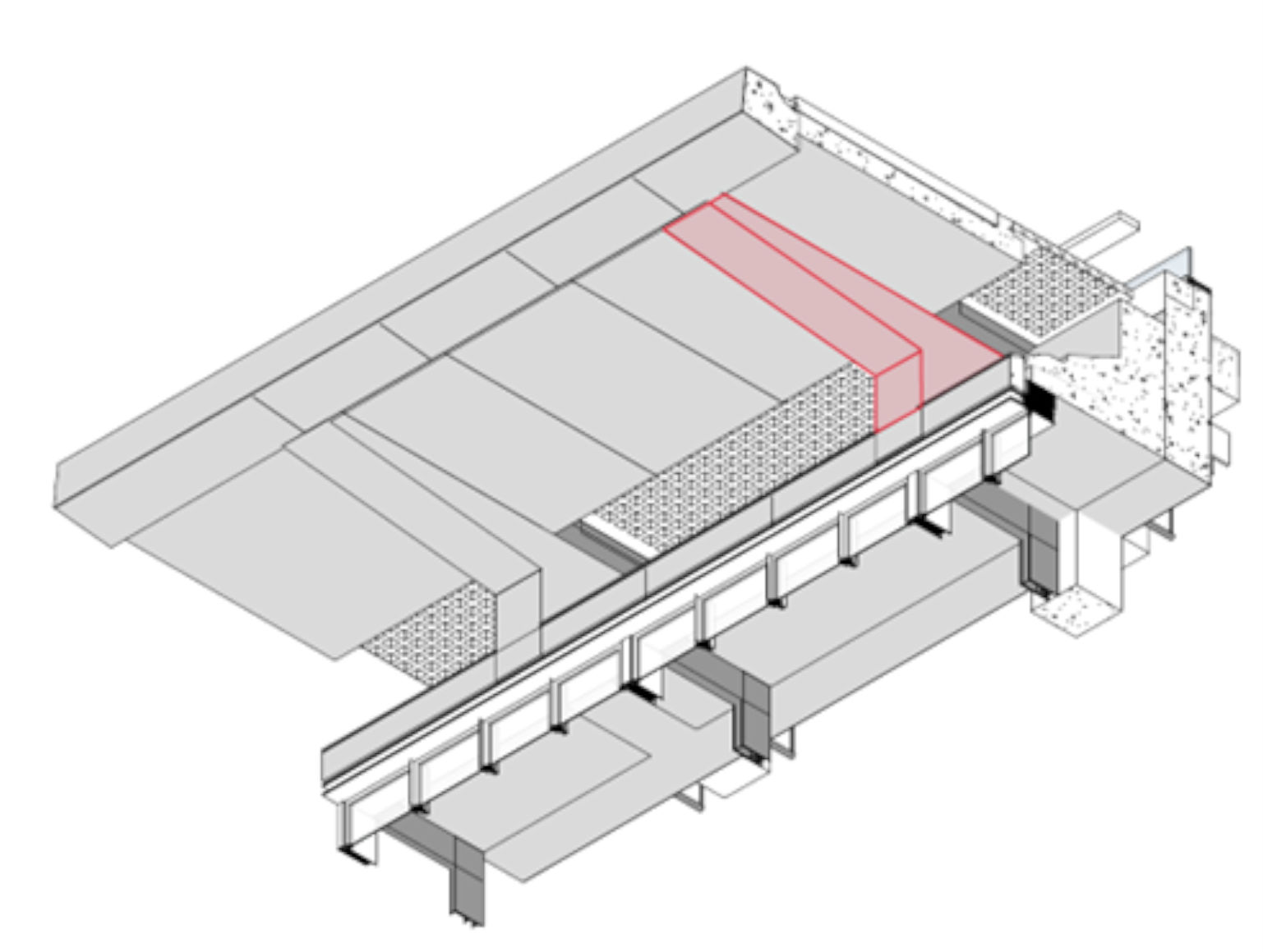

The canopy is 51m long with very high support loadings, carried by the end profile of the in-situ RC cantilever beams – each 500mm wide x 950mm deep, with a cantilever of 4.6m. The span between the beams is 4.2m with 12 beams along the canopy length. In the normal permanent condition the moment and shear loads were 900kNm and 360kN respectively. Due to the complexity of the loads and arrangement of the bespoke Schöck Isokorb elements required to transfer such high forces into a relatively small concrete beam section, the support rods were designed using Finite Element Software. The cantilever beams, aligned with internal supporting beams, allow the Isokorb rods to penetrate far enough into the structure to distribute the demanding loads. In addition, it was necessary to consider bomb blast loading which introduced uplift forces. So the design had to accommodate loads in both positive and negative directions for both moment and shear.

Deflection and natural frequency

Tight deflection requirements and natural frequency had to be overcome too and the detailing was again calculated using Finite Element Software. The contractor and design teams providing values for both long-term deflection and dead load deflection only, which determined the amount of pre-camber required during construction. This was a challenging section to calculate, due to the additional support factor of the raked end which sits on a rigid wall.

Expansion and contraction issues as well

The length of the main canopy and size of the rods required to transfer the main forces, meant that thermal stresses would be caused by the expansion and contraction of the external concrete. Expansion joints therefore had to be introduced at every third beam (approximately 8.4m centres) which carry the load from one set of precast canopy sections onto the supporting beam. Here Schöck incorporated its new heavy-duty Stacon shear force dowel type SLD. This new dowel is a uniquely compact product and as the anchoring bodies have been reduced in size, it has the advantage of enabling higher loads to be installed in thinner slabs and walls, optimising on-site reinforcement.

Totally verifiable performance

The dependable and fully compliant Schöck Isokorb range helps projects meet full compliance with the necessary UK Building Regulations. There are solutions for concrete-to concrete, concrete-to-steel, steel-to-steel, renovation projects – and even a maintenance free alternative to wrapped parapets. All products have the security of independent BBA Certification, which provides NHBC approval. Also, the new Stacon dowel has been awarded UK Technical Assessment (UKTA) along with fire protection classification R 120.

Contact Schöck on 01865 290 890; or for full details of the Isokorb product visit the solutions page on the website here.

Schöck choreographs bespoke canopy at Sadler’s Wells East

| T | (01865) 290 890 |

|---|---|

| F | (01865) 290899 |

| E | design-uk@schoeck.com |

| W | Visit Schöck's website |

| Staniford House, 4 Wedgwood Road, Bicester, Oxfordshire, OX26 4UL |

resized-comp212922.jpg)