The Field House is a ‘modern country house’ set in the Cotswolds, offering a 21st century vision of a traditional country house and its landscape. Special consent was sought through the National Planning Policy Framework, which allows certain new homes to be built in Areas of Outstanding National Beauty. Historically, country houses tended to impose themselves on their surroundings, but Field House is designed to integrate with the landscape. Traditional themes are reinterpreted as part of the modern design, including the forecourt; the gate house and the principal courtyard. The main living space of the house features a rammed earth wall that supports the concrete roof terrace structure; and the external walls of the house are constructed from rammed concrete, a dry concrete mix compacted between shutters.

Preventing thermal bridging was crucial

Special consideration had to be given to the avoidance of thermal bridging, particularly with the parapets and columns. As the architecture and structure of Field House are closely integrated, there was a high degree of collaboration between Bath and London based Integral Engineering Design and South Wales based Loyn+Co Architects. James Stroud, a director at Loyn+Co comments: “Minimising the risk of thermal bridging at critical connectivity areas throughout was an important consideration. We had no doubts that the Schöck product solutions used would exceed the performance requirements. As a result we incorporated the Isokorb XT type A as parapet thermal breaks and the Sconnex type W where columns needed to be thermally broken”.

The Isokorb as a parapet thermal break

Parapets are as prone to thermal bridging as balconies and the Isokorb XT type A offers a thermally efficient, cost-effective and maintenance free solution – avoiding the need to wrap the perimeter of the wall with an insulation barrier. It is extremely durable and impermeable to water – so no maintenance is required – and the 120mm insulation thickness of the product dramatically reduces heat loss. It is assessed as a ‘Certified Passive House Component’, provides BBA Certification, LABC Registration, NHBC approval – and meets full compliance with the relevant UK building regulations.

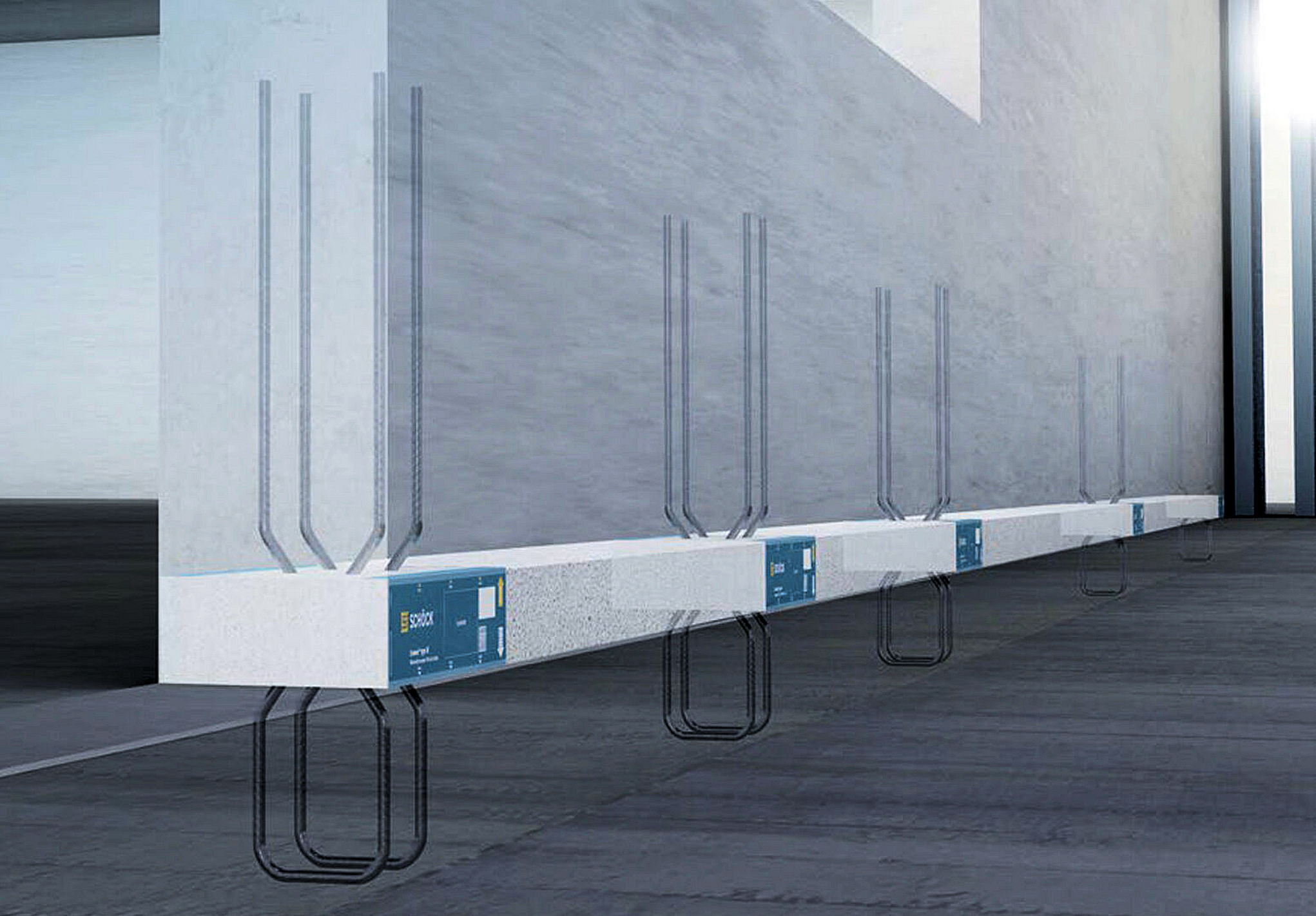

A new solution for reinforced concrete walls

Around 40% of all thermal bridges in a building are caused by walls and supports, which are responsible for about 10% of heating energy losses. The recently introduced Schöck Sconnex type W offers an application-friendly, high-quality solution which minimises the thermal bridge between the exterior wall insulation and the insulation above the floor slab. Heating costs are lower and the linear thermal transmittance (Psi) of the connected reinforced concrete wall is reduced by up to 90 percent. This outstanding insulation performance is combined with an excellent load-bearing capacity, which transmits very high pressure, tensile and shear forces in the longitudinal and transverse direction. This is due to a pressure buffer consisting of ultra-high performance fibre reinforced concrete, which achieves compressive strength in excess of 175 N/mm2 – but with extremely good flexural strength as well. There is also a significant cost reduction when compared to installing insulation beneath the floor slab.

For full information on the entire range of Schöck structural building components contact the company on 01865 290 890; or visit the website at www.schoeck.com

Schöck thermal bridging solutions for ‘21st century country house’

| T | (01865) 290 890 |

|---|---|

| F | (01865) 290899 |

| E | design-uk@schoeck.com |

| W | Visit Schöck's website |

| Staniford House, 4 Wedgwood Road, Bicester, Oxfordshire, OX26 4UL |

resized-comp212922.jpg)