A blog by Gripsure... As the name suggests, at Gripsure we specialise in non-slip deck boards and pride ourselves on the quality and performance of our products. In this blog we look into slip ratings, how they are measured, potential hazards and consequences of inadequate protection and why it is important to choose a product which will provide a safe surface in the long term rather than in the first stages of a product's life cycle.

Slip ratings

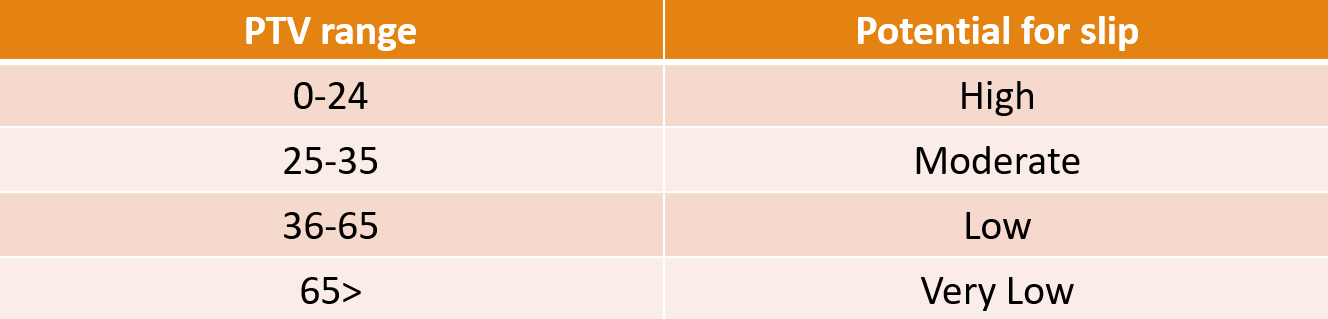

With safety being a paramount consideration for choice of material, end users and specifiers need to be certain that the product will be safe in all weather conditions and will pass the test of time. The primary way this is done is by checking the Pendulum Test Value (PTV) of a product against the Stanley Pendulum test. This test measures the coefficient of dynamic friction in accordance with BS 7976 and the UK Slip resistance Group's guidelines. This is a widely used measure for all sorts of surfaces.

On the Stanley Pendulum test, one of two sliders can be used which are attached to a weighted 'shoe'. This is allowed to swing downwards from a horizontal starting point. The weighted 'shoe' is mounted on a spring loaded bracket and will make contact with the surface for a known distance. The height to which the weighted 'shoe' reaches after making contact with the surface will give the surface a measured PTV.

The two common sliders which are attached to the weighted 'shoe' are both made from rubber. Slider 96 is used to imitate the sole of a standard shoe. Another, less abrasive rubber, called slider 55 is used to simulate bare feet. To get the final PTV of a product, the surface is tested in three directions (width ways, length ways and diagonal). Each direction is tested 8 times in dry conditions and 8 times in wet conditions. The first three readings in each condition is discounted. The final dry and wet condition PTV is the mean value of the combined 15 readings. These results will only give a product its initial PTV (like a snap shot) and consideration should be given into how the product will perform into the long term which is explained later on in the blog.

To achieve a low slip risk, a surface must score a minimum PTV of 36. Anything under 36 then you are at risk of personal injury. All surfaces will achieve a low slip potential in dry conditions, but not in the wet. All timber deck boards without non-slip inserts will present a slip risk in wet conditions. Depending on the product and the non-slip configuration of the board, Grispure's range of products with aggregate inserts will achieve a minimum initial PTV of 85. Further information can be found on our slip test results page.

Potential hazards

There are a number of potential hazards on decks. The most common hazard is standing water after rainfall. Depending on the season and the amount of rainfall, decks can stay wet for weeks. Even a quick shower in the summer months, water will stay on the deck surface long enough for them to present a hazard. Users of the deck can quite easily fall on slippery decks and cause personal injury.

Other hazards include slipping on boards where a maintenance regime has not been upheld. If boards are not cleaned of surface debris, then they are at risk of having a build up of dirt and grime which can be slippery like standing water. In the winter months, decks like other surfaces will also be slippery in icy and snowy conditions. The HSE estimate that 1/3rd of all accidents occur because of slips and trips. With this being such a major reason for injury it is very important to protect people.

If someone is injured on a deck, then the property / land owner may be liable against compensation and insurance claims. This can be very costly to first meet those claims and then secondly to make the surface safe to prevent it from occurring again. It is much more cost effective to protect people and get things right first time round by choosing deck boards with non-slip inserts.

Long term solutions

The only way to mitigate the risk of personal injury completely is by using deck boards with non-slip inserts. These boards have resin bound non-slip aggregate added into the boards and sit proud of the timber. This gives the user of the deck a secure footing every time, even in wet conditions. No other solution on the market will provide a better safety performance. Retrospective solutions will only work for a limited time and are not cost effective as they are normally labour intensive.

Composite decking boards are often marketed as a low slip product. What is often overlooked is that manufacturers will only only state an initial Pendulum Test Value (PTV). This means they are giving ratings of boards which have come straight from the production line and into a controlled testing environment. What needs to be considered is that the PTV of deck boards will fall over time as they are exposed to the different elements, build up of dirt from footwear and rainfall in between maintenance schedules, and footfall on the deck. The PTV of boards that have been in situ for a number of years will be less.

If a deck board only just scores above a PTV of 36 (which the majority of composite deck boards do), then it is likely that the boards wont be safe over the full service life of the product. The only way to protect users, is by using a board with non-slip inserts which will provide a very high initial PTV which wont drop to a unsafe level over time. The photo below shows a composite board which no longer offers adequate protection so signs have to be displayed warning users. This does not remove the risk, as users (especially children) may not read the sign and is not an adequate solution.

As well as getting our boards tested for initial slip ratings, we have also tested our boards which have been in situ at The Eden project for over ten years. The Eden Project has used our boards for visitor walkways across the site including within the world famous biomes themselves. We chose boards from this site, as the boards get heavy use so it would reflect the robustness of our product. What we found was that the PTV of the boards fell by 30 points. As our boards achieve a very high initial PTV, this drop still means that our products are above the minimum requirement for a low slip potential surface and the initial PTV of every composite board on the market.

Slip ratings, hazards and solutions for deck boards [BLOG]

| T | (01726) 844616 |

|---|---|

| E | info@gripsure.co.uk |

| W | Visit Gripsure UK Limited's website |

| Unit D2 (23), Rockhill Business Park, Bugle, St Austell, Cornwall, PL26 8RA |

Products by this Company