Within construction, we’re all aware of the amendments to Document B in 2019 that banned laminated glass on buildings over 18m in height. It has been a topic of conversation for the past few years and one that is still discussed widely today, particularly in relation to the frequently asked question; what are the alternatives?

The Ban was issued as a result of the Grenfell Disaster and has meant that as Architects and Designers within Construction, we are lot more cautious when designing buildings to ensure they’re designed in accordance with building regulations and to the correct specification, particularly in relation to external materials specified on the façade of the building. Further information to the background to the ban can be found on an article published in July 2019 here.

BA Systems has been doing extensive research into the B40 Glass Balustrade product to enable us to bring a product to market that comprehensively meets the requirements of the A2-s1,d0 standard. This guide aims to explore the components of this system and how they achieve their A2 Rating.

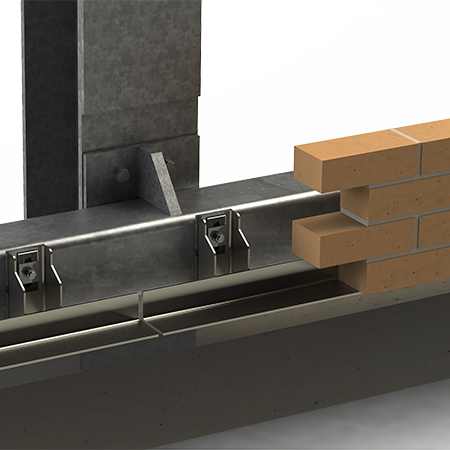

The below section detail provides a visual overview of a typical glass balustrade detail. It outlines areas on the balustrade that may present compliance issues and references the relevant sections on this report to demonstrate the system compliance with the A2-s1,d0 standard.

Whilst we cannot certify the system as a whole due to there being no regulation to certify it to, we can provide confidence that each individual component of the system is tested and approved as A2 Rated.

These are the risks and mitigating factors to consider when specifying a glass Balustrade for Buildings over 18m in height. BA Systems B40 A2 Rated Glass System will provide a product that is fully certified to meet the current regulations and therefore permitted for Buildings over 18m in height.

Combustibility of the channel fixing wedges

Many systems on the market use plastic wedges to secure the glass in the channel. Whilst this does offer a high degree of adjustability, it does present a significant risk in event of a fire. The plastic wedges are not designed tested to A2 s1, d0 Standards. In the event of a fire, the heat could cause the wedges to fail and the glass to become loose. This poses a very high risk. BA Systems will mitigate the risk by specifying a grout product that secures the glass in position effectively. The grout is a Cementitious product (A1 Rated), therefore has no combustibility issues. In event of a fire, the heat will actually draw out the moisture from the grout which ensures there is no fire spread.

Combustibility of the laminated glass

Traditional laminated glass products use a PVB or SGP interlayer which does not meet the minimum fire rating requirements as outlined in Approved Document B. Although there is very limited exposure of the interlayer to the fire (just the edges of the glass), it is deemed as a fire risk. BA Systems will specify a glass product that has full A2-s1,d0 certifications. Report available on request to show this.

Combustibility of the powder coated finish

Some powder coatings on the market do not meet the minimum fire rating requirements as outlined in Approved Document B. Although a low risk, it could contribute to fire spread. BA Systems will specify coatings that have full A2-s1,d0 certifications. Report available on request to show this.

Contact one of the team to find out more about the system and how to specify! BA Systems provides a full and comprehensive design, manufacture and install service of our balustrade and handrail products and systems.

Understanding the A2 Rating of Glass

| T | (01603) 722330 |

|---|---|

| F | (01603) 722777 |

| E | sales@firma.co.uk |

| W | Visit FIRMA's website |

| 22 Bidwell Road, Rackheath Ind Est, Norwich, Norfolk, NR13 6PT |

Categories

Sections Stairs Glass Stair components

-comp212644.jpg)