After the devastation of the Second World War, the Elephant and Castle district of London was clumsily redeveloped during the 1950s. The resulting offices, housing estates and shopping centre were impressive in their time, but at best outmoded in recent times.

Today, the £2.3 billion Elephant Park regeneration project now aims to create one of the most sustainable inner-city areas in Europe.

Overall there are five phases, the third of which is currently live with eleven buildings divided into two plots – Park Central (North) and East Grove – providing 829 homes in total.

There are brick-finished midrise blocks to 11 and 12-storeys throughout with each plot also featuring a main tower. One at 24-storey, the other 25-storey, both part of the family of tall buildings in the masterplan.

Construction of the towers uses around 19,000 m2 of aluminium unitised façade panels supplied by FKN and Lindner, delivered complete with integrated sliding doors and openings ready for the connection of ventilation devices.

There are hundreds of cantilever steel balconies throughout the project too, also pre-fabricated (including flooring and glazed balustrades) and supplied by Dearneside Fabrications Ltd.

Avoidance of thermal bridging is critical

With steel having such high conductivity, the avoidance of thermal bridging is critical throughout the project.

Local heat loss is a major factor, resulting in more energy being required to maintain the building’s internal temperature.

Also, low internal surface temperatures local to any thermal bridge can cause condensation. This is likely to result in structural integrity problems with absorbent materials, such as insulation products or plasterboard and mould growth is also a possible risk, which in a residential situation can cause asthma and allergies.

The thermal performance at the connectivity points throughout – involving both the balconies and the commercial façades – needed careful consideration.

Although the Schöck Isokorb structural thermal break is universally recognised for its capability with balcony design detailing – it is less widely known for its ability to also dramatically improve the thermal performance involving façade engineering.

On this project, as the thermal zone sits outside the slab zone, the Isokorb is the ideal solution and the specific product offering so many benefits is the Schöck Isokorb T type S.

Unique and versatile

The versatile Schöck Isokorb T type S structural thermal break is the ideal connectivity solution for steel-to-steel applications.

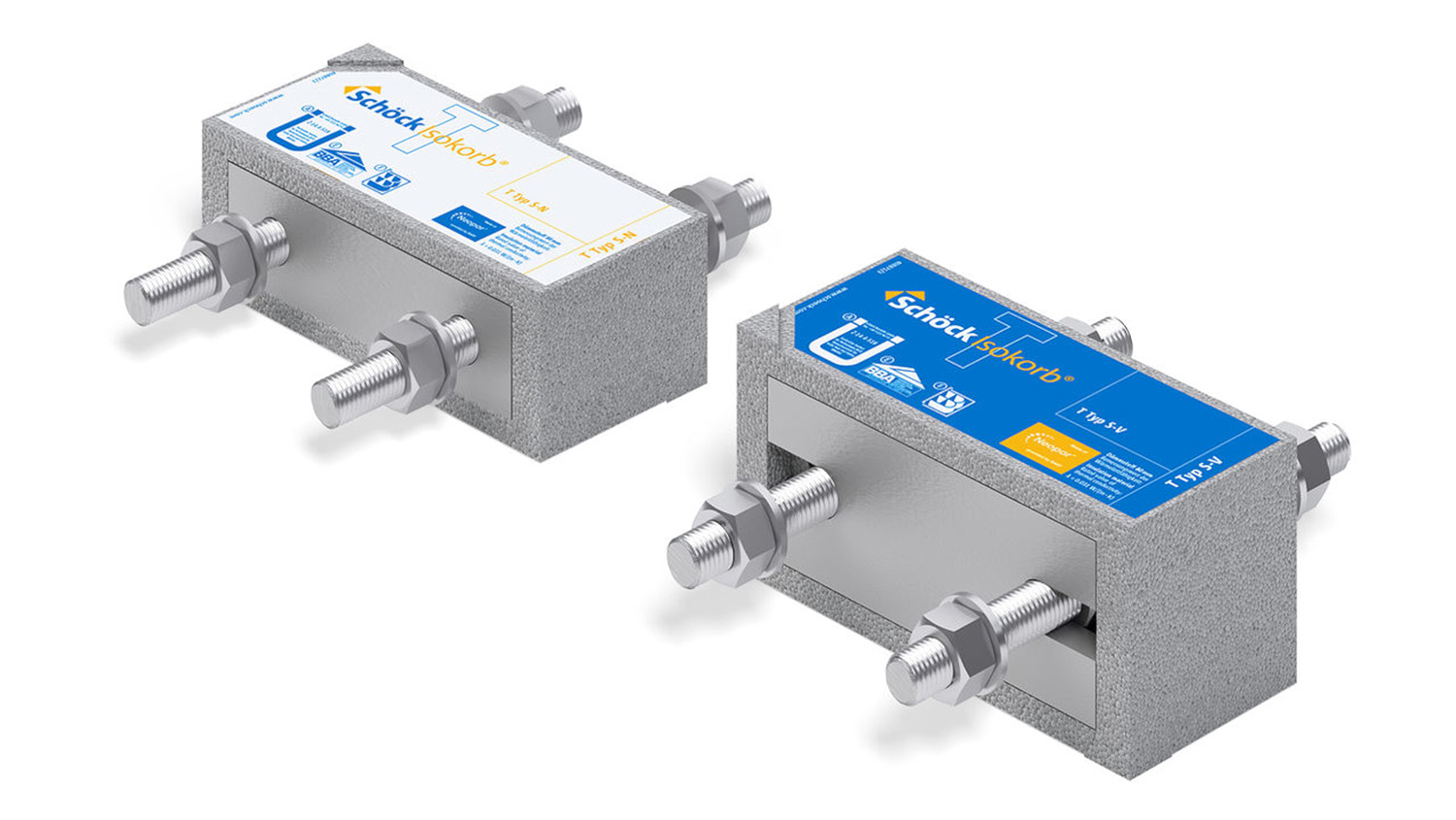

There are two variants, the T type S-N for tensile force and the T type S-V for transferring compression and shear forces.

It is the only approved thermal break product that satisfies the load-bearing and thermal insulation requirements for steel design.

Also, being a modular unit, it can be adapted to all profile sizes and load bearing capacity requirements – plus it can be used in both new construction and renovation projects.

Totally verifiable performance

Although the Schöck products used at Elephant Park are for steel-to-steel connectivity, the comprehensive Isokorb range also offers solutions for concrete-to-steel, concrete-to-concrete – and even a maintenance free alternative to wrapped parapets.

Products meet full compliance with the relevant UK building regulations, have NHBC approval and offer LABC Registration.

There is also the security of independent BBA Certification. The requirement that the temperature factor used to indicate condensation risk (fRSI) must be greater than, or equal to, 0.75 for residential buildings is also easily met by incorporating the Isokorb.

Please visit their website for more information.

View Thermal structural connectors Product Entry

resized-comp212922.jpg)