Backflow prevention is essential for keeping domestic and commercial water supplies sanitary and safe, as it can lead to serious problems if contaminated water is consumed. Stories of contaminated water supplies are well documented, and every home and building owner hopes they won’t have to face the same fate. This is why in this blog RWC discuss industry regulations and fluid categories for domestic and commercial buildings.

Backflow occurs when tainted or stagnant water is drawn back into the mains water supply. There are two main causes, both of which are well-known – back-pressure or back-siphonage – which happens when water is pushed in the opposite direction of its normal flow pattern. So, how can installers ensure there will be no backflow and that all water supplies will be safe and sanitary?

Knowing the right regulation for the right application

Of course, the most important factor that installers need to think about is whether they’re adhering to the right industry regulations. The Water Supply (Water Fittings) Regulations (1999) for England and Wales (Byelaws in Scotland) has established five fluid types, each indicating a higher level of danger, to help mitigate the issue of backflow. Fluid Category 1 is regarded as safe, while Fluid Category 5 poses a significant health risk. As these are crucial to know, we’ll go into the different categories in more detail later.

Contaminants in clean water pose a serious and immediate threat to human health. This is problematic for any building, but the risk is significantly greater for hotels, schools, hospitals, and other healthcare facilities where the system is always in use in these spaces, and potentially vulnerable or at-risk individuals could consume contaminated water.

Categories are crucial

Understanding the expected level of fluid risk for the building in question, as well as what level of protection will be required, is the key to managing backflow regulations. The location of the water appliance will determine the level of backflow protection that is required. Let’s break them down:

Fluid category 1 and 2

Fluid category 1 – ‘wholesome water’ which complies with section 67 of the Water Industry Act 1991 – requires no specific countermeasures or action. Fluid category 2 covers water which has altered in either appearance or taste, with likely causes being either a temperature change or the presence of micro-organisms or other substances. Here, a single check valve will suffice.

An example of this is a basin mixer tap, where hot water can sometimes pass back into the cold supply – installing a single check valve to the cold pipe feeding the tap would prevent cross flow from occurring.

Fluid category 3

Fluid category 3 represents water with low levels of toxicity which nevertheless present a slight health hazard. In these cases, double check valves must be installed. One instance of this would be a supply to an outside tap – unless this supply is feeding a sprinkler system that uses pesticides, in which case higher protection is required. Baths and showers in most domestic situations are also categorised as a fluid category 3 risk. In the event of shower hoses being submerged in a bath or shower tray in a domestic situation, then the above backflow protection options must be installed.

Fluid category 4

The more significant health hazards begin with Fluid category 4, which is water with harmful concentrations of toxic substances. Suitable backflow prevention devices are required in these situations, such as RPZ valves.

You can read the blog here specifically looking at RPZ Valves and backflow prevention in commercial buildings.

Fluid category 5

The highest risk level of all – Fluid category 5 – represents the most serious health hazard because of the presence of pathogens and radioactive or very toxic substances. Fluid category 5 is a highly specialist area calling for a Class 5 backflow prevention device, incorporating a Type AB air gap or equivalent.

Pressure is make or break

So, those are the regulations, but why does backflow happen in the first place? In essence, it’s all about pressure.

The pressure of mains water is generally maintained between 1 and 4 bar, allowing it to flow from taps and other outlets. This pressure also assists in the protection of the mains water supply against contaminants. By guaranteeing this internal pressure, it means that any impurities are removed from the appliance when the water outlet is opened, and prevents anything from entering the water system.

Backflow, on the other hand, can occur when this pressure fails. This can happen as a result of burst pipes or while mains maintenance is being undertaken. These circumstances can occur on construction sites, in nursing homes, and in private properties. In homes, exterior taps and hose pipes left on the ground are particularly susceptible to backflow – any drop in water pressure can cause the supply system to ingest chemicals from fertilizers into the hose.

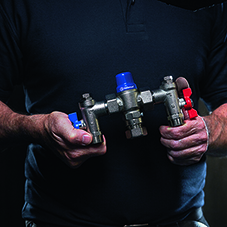

To prevent backflow, there are a range of valves available, from single check to double check valves, through to more specialist devices like RPZ Valves for commercial and healthcare settings. These valves allow water to flow only in one direction, preventing the reverse flow of water and any harmful chemicals reaching the home or building. The first thing to know when installing a check valve is the fluid category you’re dealing with, which can be discovered on the water regulations website. As a rule of thumb, double check valves are recommended for appliances that use hot water, cleaning agents, or chemicals, to be double sure that backflow won’t occur.

Backflow clearly poses a significant threat. There are, however, simple and effective ways to prevent this from happening and to maintain a constant supply of safe, clean water. Reliance's solutions portfolio offers these options, as well as the backing of an experienced technical team that can provide installation advice and recommended practice.

At RWC, they are here to help you all the way, from technical support through to best practice installation guidance so if you have a question please get in touch.

Backflow basics – The regulations you need to know

| T | (01895) 425333 |

|---|---|

| E | Info@RWC.com |

| W | Visit RWC – Reliance Worldwide Corporation's website |

| Horton Road, West Drayton, Middlesex, UB7 8JL |

(002)-comp104848.png)