Client: Burdens

Type of works: new ACO channel drainage system overcomes major challenges in merchant’s stockyard.

The channel drainage system installed by ACO Technologies at Burdens’ new depot on the outskirts of Cambridge ensures that the yard’s 10,000m2 of hardstanding is effectively drained even though the site has virtually no fall and the water table lies just below the surface. Designed by the team at ACO Technologies, the system uses a series of high capacity ACO S Range heavy-duty channel runs to provide the required hydraulic capacity and to create sufficient internal head to discharge surface water run-off from the site at the rate specified by the Environment Agency.

“The intention was to discharge surface water from the new yard into a soakaway that runs adjacent to site. However, the high water table meant that we only had a maximum depth of 400mm in which to install a drainage system with sufficient capacity to manage the run-off from such a large area,” says Alan Hampton, Property Consultant for Burdens. “We have been stocking ACO drainage systems since 1988 and were keen, in this situation, to see if ACO’s design team could come up with a cost effective answer to the considerable challenges at the site.”

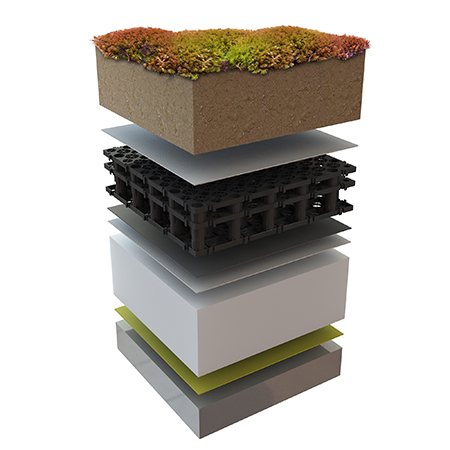

The key element to the successful solution that ACO’s team has designed is a linked, double run of ACO S300 that receives run-off from a network of smaller S200 and S100 runs across the site. The ACO S300 channel has a depth to invert of 360mm, allowing it to sit within the available depth on the site. The parallel runs of channel, which do not include any additional sumps or pipework, provide sufficient capacity to cope with the design storm rainfall intensity of 55mm/h.

By using the limited fall across the site and the natural head that establishes itself within the channel when charged with run-off, ACO’s engineers calculated that the hydraulic flow characteristics of the completed channel system would allow surface water to discharge, via an oil separator, into the soakaway to be constructed to the side of the site.

“The depot became fully operational during the summer when the country was experiencing exceptionally high rainfall, an excellent test for the new drainage system,” says Alan Hampton. “Even under these extreme conditions, the system behaved just as ACO had predicted. There was no surface water ponding, the discharge rate from the site remained constant and we were able to operate throughout as normal.”

All the ACO S Range drainage channels are rated at Load Class F 900 (90 tonnes). Manufactured from high-strength polymer concrete, each channel section is fitted with a slotted cast-iron grating that is locked down by eight bolts. Ideal for distribution yards, storage depots and locations that experience high axle or point loads (such as those created by forklift trucks), the S Range is available with a wide range of sump and gully accessories that allow the creation of extensive and versatile high-performance drainage networks.

View Surface Water Channel Drainage Product Entry View ACO S Range PDF