EJOT UK’s product range and 360-degree service is enabling the maximum value and energy saving benefits to be leveraged from external wall insulation (EWI) systems.

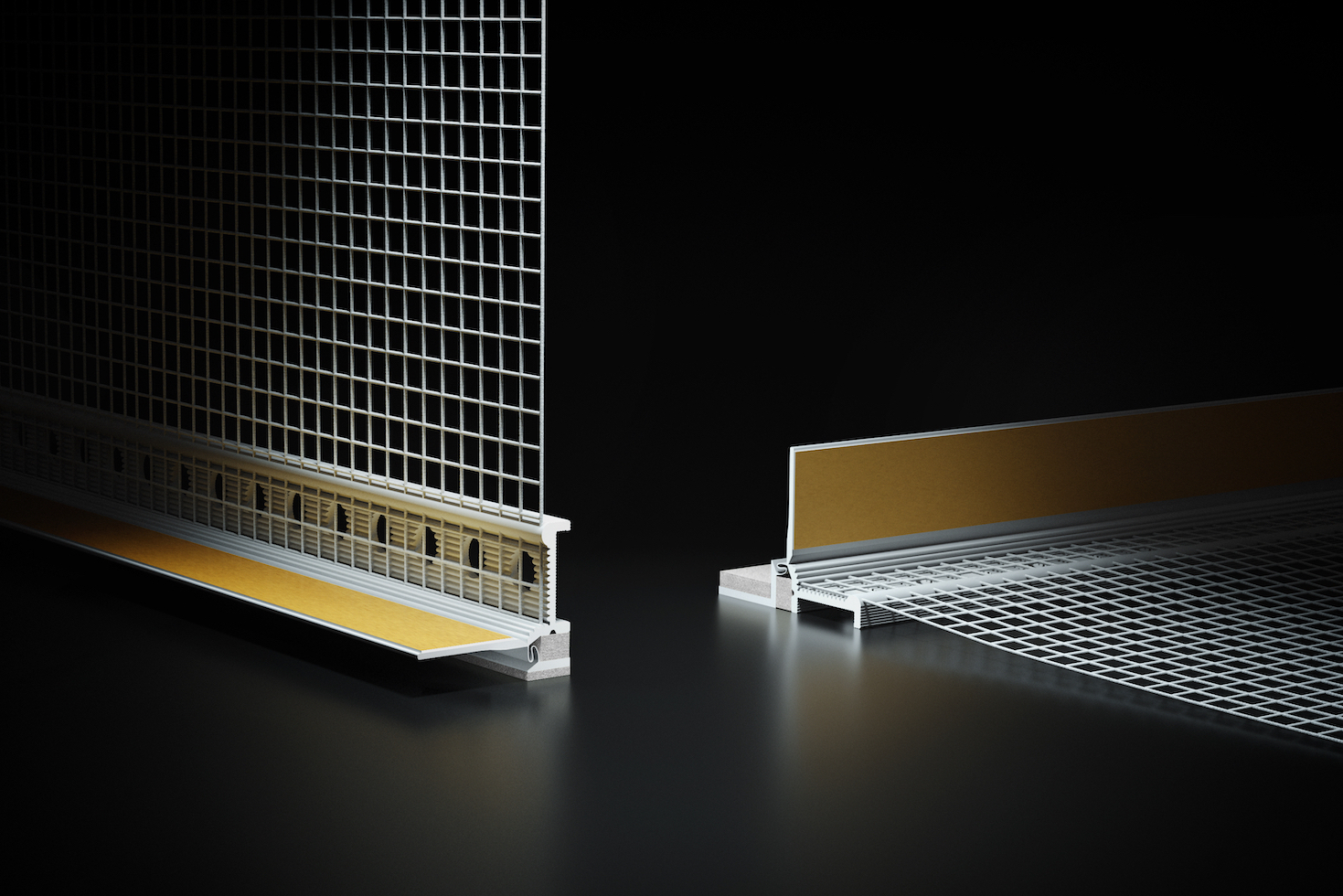

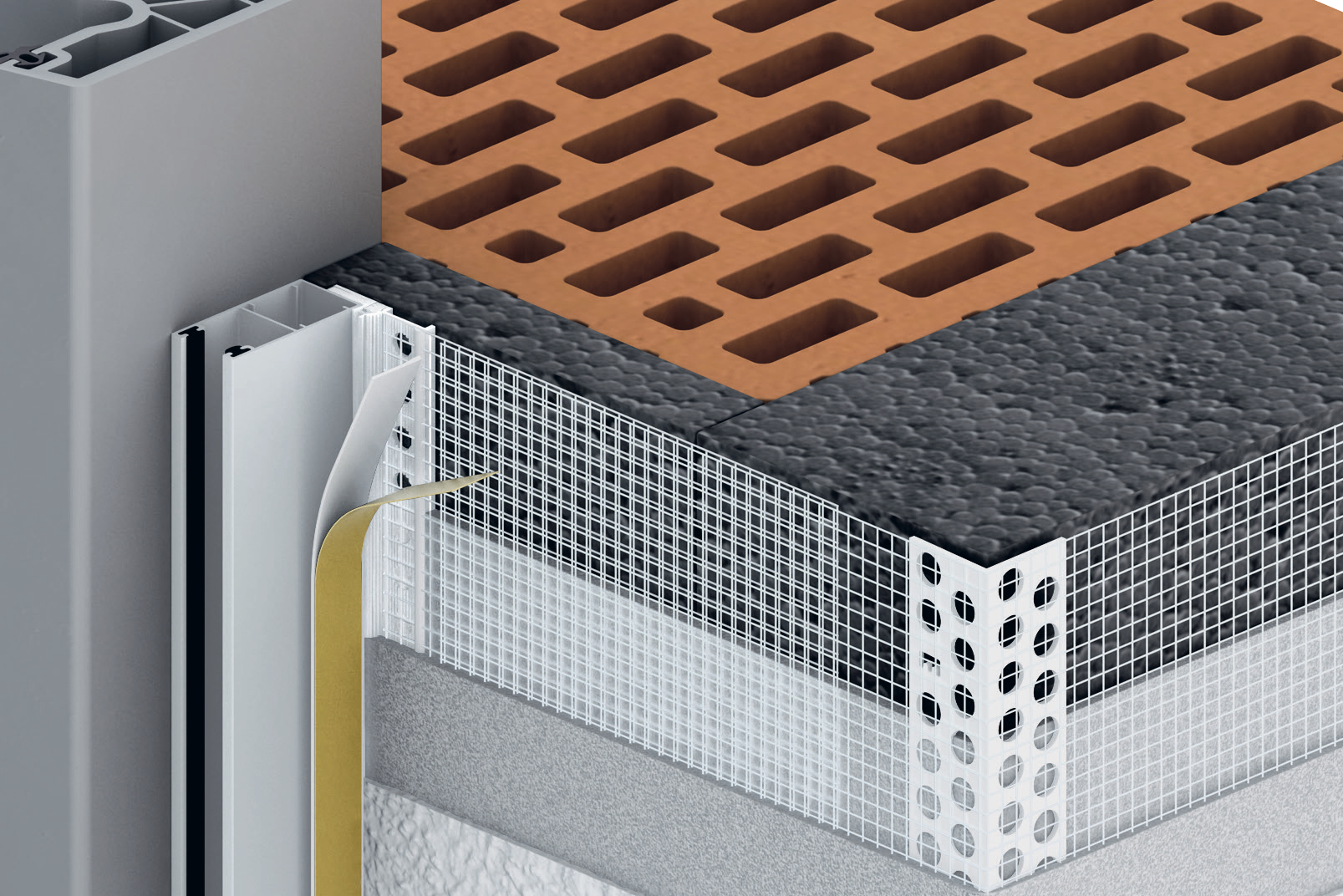

Its comprehensive range of insulation anchors, fasteners and post-install mounting elements for installing EWI, also known as ETICS (external thermal insulation composite systems), has recently been extended with the addition of a number of new innovative PVC profiles and beads. These are fundamentally important for built-up EWI systems to deliver on their promise, as any failure in these structural components could mean the built-up layers, including the insulation, are less effective at thermally insulating the building and deteriorate prematurely, resulting in the need for costly remediation.

To ensure EJOT UK supports the sector most effectively, it has adopted a three-fold strategy. This is made up of a comprehensive technical development and testing phase to maintain a complete component and profile offering, plus a focus on optimisation of its processes to provide a streamlined and reliable supply chain for products.

The third dimension is providing world-class support to all those in the supply chain so that they have the data, training and knowledge to understand how to correctly integrate the products from design to installation.

EJOT UK calls this a 360-degree service. It starts at the design stage of a system or proposed EWI project when the company works closely with the design team to develop the most effective anchoring approach. This includes conducting pull-out tests on-site and using EJOT’s digital product configurator to arrive at the appropriate product combination, such as the EJOT ejotherm® STR-U 2G anchor complete with a pre-mounted screw.

This is an important area given that the choice of anchor will impact on the system’s thermal performance, the compatibility of insulation types possible and their thicknesses, as well as the overall cost given that advanced designs like EJOT’s may mean fewer anchors are necessary.

In these early stages, EJOT also works with clients on the pre-dimensioning of mounting elements for planned attachments. These are products such asEJOT Iso-Corner and EJOT Power-Bloc, which are designed to be fixed to the building substrate as the EWI system is being installed to accommodate medium to heavy-duty attachments such as balcony railings, brackets for downpipes, wall lights and railings.

By planning their location, a safe, secure attachment can be achieved once the façade is complete which does not create a thermal bridge.

Working closely with the EWI systems companies and contractors at an early stage also enables the optimum suite of EJOT ETICS profiles and beads to be specified. The choice of these products impacts on installation efficiency and long-term performance of the EWI system, which is why EJOT’s design team in Germany have created products with innovative detailing to make a significant difference to the quality of the rendered finish, particularly at corners and around reveals such as windows and doors.

As part of EJOT UK’s on-site service, it also conducts adhesive tests with the profiles and beads to ensure they are compatible with the system build-up and target performance figures.

Clients are also supported to address unplanned attachments in situations when it is not possible to plan where, for example, a bracket may need to be attached to the façade. Post-install mounting elements, including EJOT Iso-Dart, make such attachments achievable with ease, enabling a secure fix to the substrate to be achieved through insulation at depths of up to 320mm with no thermal bridging effect.

Mark Newell, EJOT UK’s ETICS specialist said:

“The quality and performance of any building system will only ever be as good as its component parts. It may seem like an obvious statement, but it is important to highlight this in the context of the numerous other factors that influence specification and procurement decisions, not least budgetary pressures, project start and completion dates, product availability and install-ability.

“However, this is something that is increasingly being recognised in all areas of construction as more stringent standards and minimum performance levels in relation to sustainability, in particular, are encouraging greater scrutiny of systems, even down to the smallest components like the fasteners.

“By offering all three product segments, from an operational perspective we can provide significant benefits to systems providers by streamlining their supply chain, simplifying ordering, cutting the number of vehicle deliveries to sites and reducing stockholding. But the advantages are also felt by property developers and landlords too, given the quality consistency and the guarantee of quality that comes with all the ETICS components which carry the EJOT brand.”

Find out more at www.ejot.co.uk/Expanding_ETICS_range

EJOT’s complete solution maximises EWI system quality and benefits

Image Gallery

EJOT UK’s 360-degree service benefits all those involved in the EW supply chain, helping to maximise return on investment for property owners and developers.

| T | (01977) 687 040 |

|---|---|

| F | (01977) 687 041 |

| E | InfoUK@ejot.com |

| W | Visit EJOT UK Ltd's website |

| Hurricane Close, Sherburn Enterprise Park, Sherburn-in-Elmet, Leeds, West Yorkshire, LS25 6PB |