Understanding of the correct fasteners and installation techniques is crucial for ensuring that building envelopes meet their intended performance. This is why EJOT UK focuses on offering specialised training, testing, and technical support to the roofing and facades sector in the most comprehensive way possible at its state-of-the-art Applitec Centre in Yorkshire.

Innovation in roofing and cladding products continues to push the boundaries of building envelope durability and performance. For clients to maximise the benefits of these advanced systems, fixings and other components, however, it is important that everyone involved in the building envelope supply chain is aware of these latest developments – and understands their potential.

As products evolve and new ones are launched, it can be easy to assume that they are largely the same as what has come before, especially when they look remarkably similar. Where fasteners are concerned, however, even the slightest differences in the design of systems or changes to the substrates used could mean the fixing approach needs to change too. That could require a different product completely or tweaking the technique for installation to ensure it is effective with the system or substrates.

Fine margins can exist between what makes a roofing or cladding installation sub-standard and one that is first-rate, and often it is the type or quality of the fixings that makes the difference. This reflects the crucial role that fasteners play in providing a secure attachment that must resist the forces generated through wind loads, as well as ensuring the envelope achieves its air- and water-tightness goals to maximise thermal performance and prevent leaks.

Recognising this, EJOT UK has consistently invested in supporting building envelope designers, product manufacturers, installers and independent inspectors to confidently integrate the latest fastener technologies into their projects. This commitment led to the creation of application technology (“appli-tec”) centre in 2017, which has since been further expanded to deliver even greater support at a state-of-the-art facility.

A world-class R&D, testing and training facility

In 2022, EJOT completed a multi-million pound extension to its Yorkshire HQ and manufacturing centre. This new building was designed from the outset to include an expanded Applitec Centre, not only in terms of increasing the floor space within the laboratory but to enhance its environmental testing facilities. These are used to conduct salt spray and UV exposure tests, amongst many other aspects that impact the environment and sustainability.

Today's Applitec Centre facilitates testing in a number of areas, principally associated with the mechanical properties of fasteners, materials science and environmental performance. The facility supports EJOT customers in both the construction and industrial sectors, with the latter including premium car manufacturers who rely on its fastening technology to achieve their ongoing remit to design lighter and build stronger.

EJOT UK’s vision was always to serve these very different markets in a single progressive arena given the similarity of the challenges facing designers and OEMs in both sectors, and enable easy knowledge-sharing between engineers in the two. As a result, the Applitec Centre includes advanced technology and equipment of a standard that is normally only associated with academic research laboratories.

Beyond R&D, the Applitec Centre's mission extends to training and educating industry professionals on how to maximise their use of EJOT fasteners. This begins at the early stages of the building envelope supply chain, allowing EJOT to collaborate with OEMs during product development by simulating real-world applications and validating performance prior to product launch. One of its most significant contributions is to installer training.

Supporting installers to get it right first time on-site

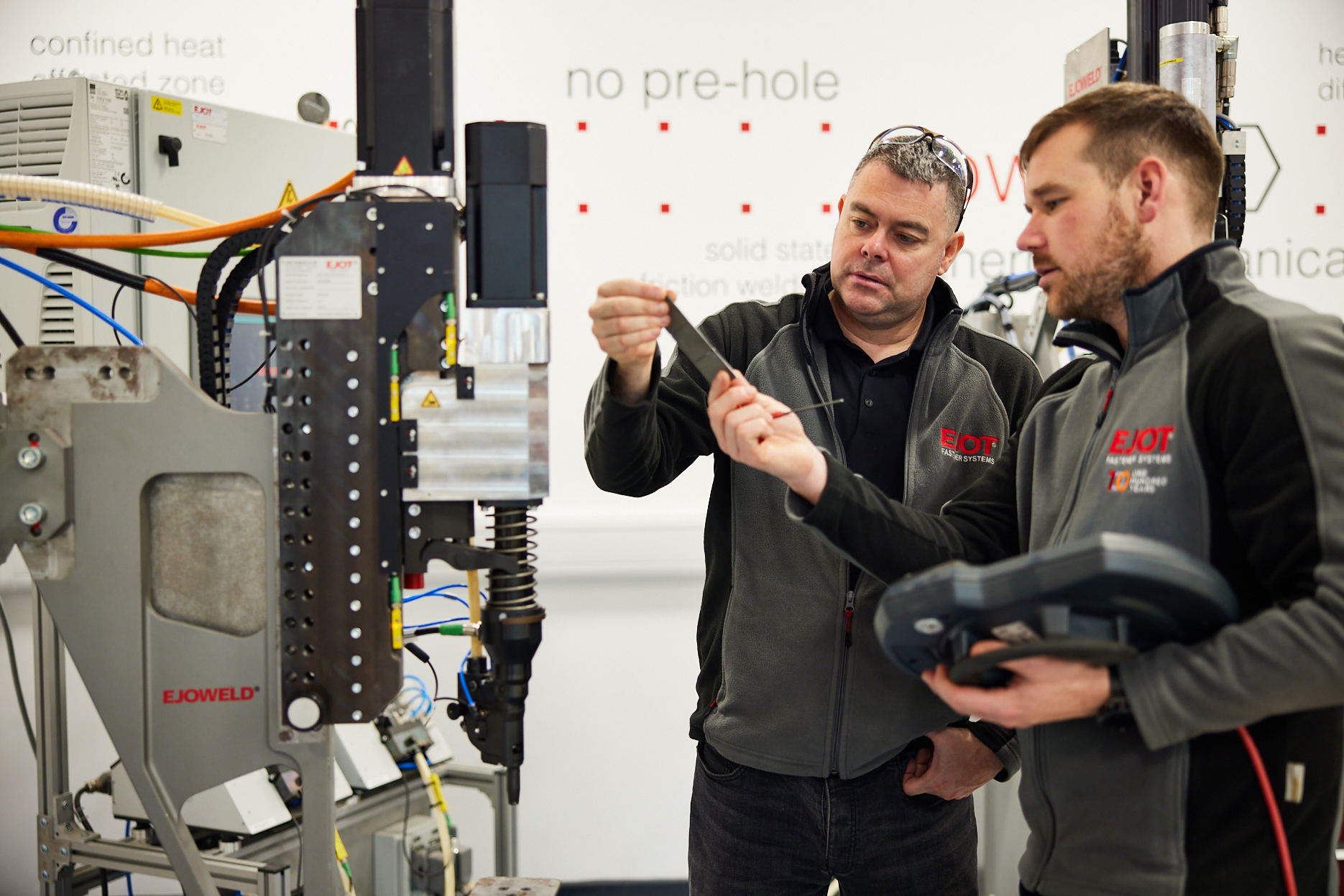

Within the Applitec Centre is a large test rig which gives the technical team the opportunity to demonstrate how EJOT fasteners work in practice when fixing roofing and cladding panels to purlins, for example. It is a permanent fixture which is used continuously, not only for training but in testing, such as to check fasteners as part of its quality control processes, or for R&D.

The rig enables installers to hone their skills and learn new techniques when working with EJOT fasteners. For example, ahead of a project start, representatives from the installation team and system providers can use the Applitec Centre to collaborate and work with the exact fasteners and metal sheets specified for the project. This helps them to perfect their approach prior to starting on-site, fully supported by EJOT’s technical team.

EJOT’s training program, however, is not limited to project-specific guidance. The company also offers broader training sessions for installers, building envelope designers and specifiers to enhance their fastener knowledge and skills, ensuring they remain up-to-date and competent in their field—a key factor under the construction industry’s stricter safety regulations like the JCI (Joint Competence Initiative).

The rig is also used for internal staff training. For example, the rig helps to provide every member of the EJOT UK team with the opportunity to understand the principles of how to install a roof, and it enables expert level training to be delivered for members of the CFA (Construction Fixings Association).

Enabling the creation of best practice resources

The Applitec Centre also enables EJOT to develop a comprehensive range of best practice resources, ensuring that even those unable to attend the centre can still benefit from EJOT's knowledge and advice.

One of the ways EJOT does this is by creating videos showing how to install specific types of roofing and cladding products using EJOT fasteners, along with comprehensive printed guides for many key products. These resources are published online and freely available for anyone to access, including its best practice for using self-drilling fasteners.

These videos, which aim to prevent issues resulting from using the wrong tools or driver settings, have been developed over time in the Applitec Centre and have already been viewed thousands of times. Similar best practice videos have also been produced for some of EJOT’s flat roofing fastening systems, which have proved to be equally popular with installers on its YouTube channel.

With the Applitec Centre, EJOT UK has created a top-tier facility that extends its support to the entire supply chain, helping to deliver building envelopes that are more durable and sustainable. This reflects the crucial role that fasteners play in building performance and highlights EJOT UK’s commitment to continuous investment in innovation and expertise.

Find out more about the EJOT UK Applitec Centre here.

EJOT UK’s Applitec Centre extends skills and training support to construction industry

Image Gallery

In this training, EJOT UK’s team collaborated with the OEM and contractor to confirm best practice for installing a particular system.

The Applitec Centre is equipped with state of the art equipment to test, analyse and prototype fasteners as part of EJOT’s quality and R&D processes.

| T | (01977) 687 040 |

|---|---|

| F | (01977) 687 041 |

| E | InfoUK@ejot.com |

| W | Visit EJOT UK Ltd's website |

| Hurricane Close, Sherburn Enterprise Park, Sherburn-in-Elmet, Leeds, West Yorkshire, LS25 6PB |