PROJECT OVERVIEW

Two Oaks is a significant housing development comprising 590 apartments and duplexes, along with communal leisure facilities and retail, in Knocklyon, Dublin. The project started in October 2021 and is due to be completed by March 2023, comprising 480 build-to-rent dwellings and a further 110 for private sale.

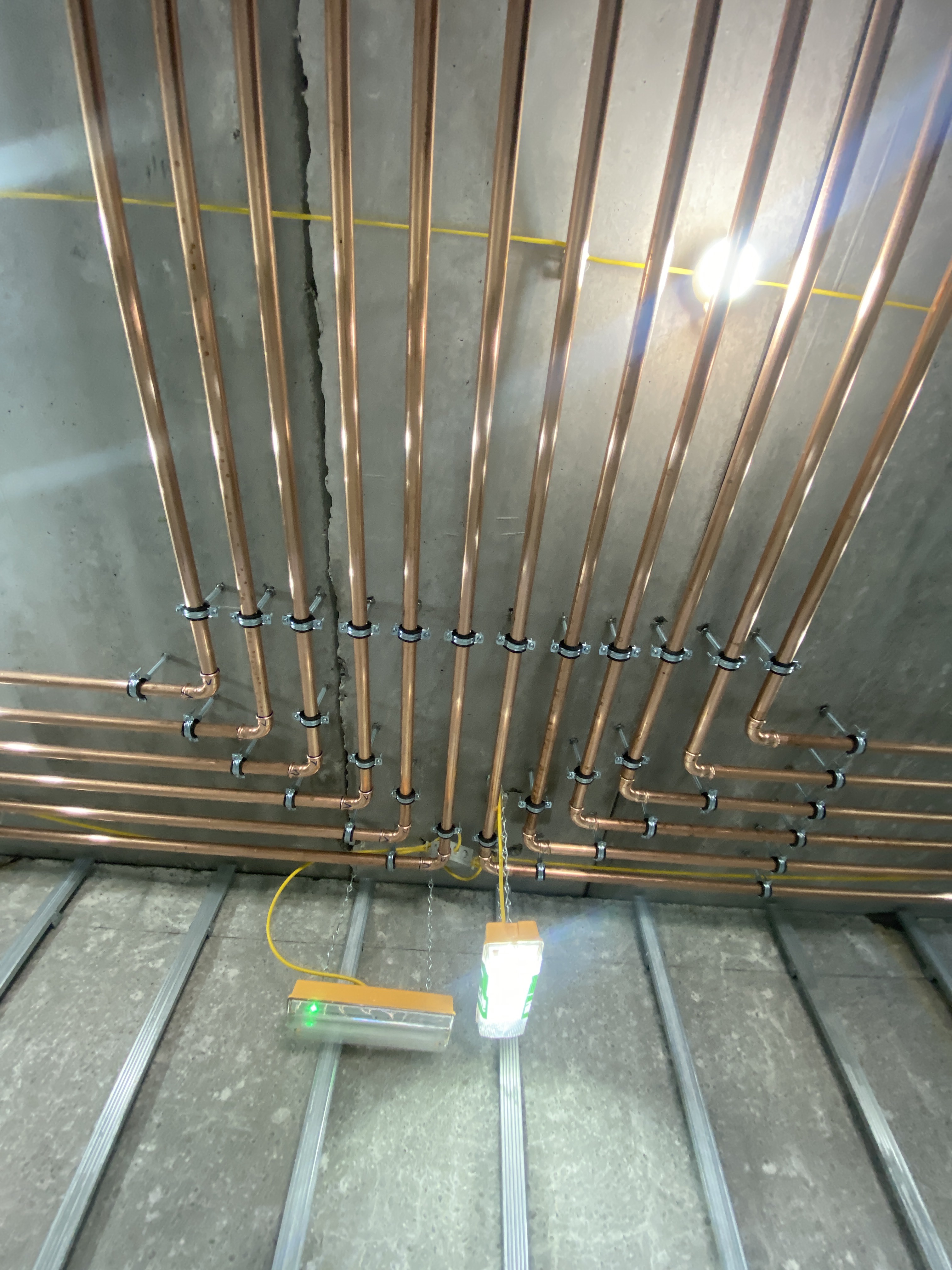

Tasked with installing the water and drainage systems for the 480 build-to-rent apartments, mechanical engineering firm Gaffney Mechanical sought a cost- and time-effective alternative to welded copper piping systems. They decided to use a press fit system and opted for Geberit Mapress.

WHY GEBERIT?

Press fitting delivers a quick and tidy installation, which reduces labour and eliminates hot works on site when compared with welding or soldering. Immediate supply of Geberit Mapress was available, ensuring Gaffney Mechanical chose Geberit Mapress over other press fitting solutions for approximately 7,000 metres of copper piping for the potable water system across the 480 properties.

With Mapress, installers simply need to cut the pipe to size, debur the inside and outside, mark the socket insertion depth on the pipe, push the pipe into the socket of the fitting, then press the joint and connecting pipe using the pressing tool.

Coloured pressing indicators on the fittings offer easy identification of the material and show any unpressed joints during the installation process. Mapress is available in a range of materials including carbon steel, copper, stainless steel, and CuNiFe, making it suitable for a wide range of applications.

Around 700m of Geberit HDPE piping was also specified for the drainage system in the build-to-rent properties, using heat welding equipment to complete the majority of works, with electrofusion collars where required.

DELIVERING THE SOLUTION

Eamonn McKeown, senior contracts manager at Gaffney Mechanical, said:

“It was clear that Geberit’s Mapress system would deliver benefits for us on site and with immediate supply – plus the addition of HDPE piping from a single supplier - it was an easy decision for us to choose Geberit. The client benefits from a quicker and tidier installation, and we’re able to move onto the next property safe in the knowledge that the connection is reliable. The use of a hot plate welder provided us with the benefit to fabricate spools off site and also on benches on site within a quality-controlled environment. This ensured a quality weld every time and reduced the possibility of in situ leaks thus reducing re-works time.”

Geberit is The Perfect Fit at Dublin's Two Oaks Residential Development

| T | (0800) 0778365 |

|---|---|

| F | (0844) 8006604 |

| E | enquiries@geberit.co.uk |

| W | Visit Geberit Sales's website |

| Geberit House, Edgehill Drive, Warwick, CV34 6NH |