Key to continuously improving fastener performance is maintaining a thorough understanding of the substrates in which the fasteners are being used. Without knowledge of how a roofing or cladding assembly will respond to the fastener, there is no way of knowing how innovative features incorporated into a fastener will be effective in achieving a secure fix that stands the test of time.

The study of ‘materials science’ has become critically important for fastener manufacturers in recent decades. The way we build is changing. Newer lightweight metals and composites have grown in prominence to support building lightweighting and sustainability goals, in particular, challenging the norms of how we would expect a roof or façade to be formed.

This has resulted in an increased focus within the EJOT UK technical team on ensuring that the slightest changes in substrate composition, thickness or form can be accommodated by its fasteners. It is a specialist area of research, testing and development that the company’s Technical Manager, Jon Knaggs, leads on, supported by the state-of-the-art equipment within its Applitec Centre at the company’s HQ in Yorkshire.

Jon and his colleagues in the technical team handle a wide variety of day-to-day customer requests for assistance, ranging from technical data and support for testing to investigating site issues and advising on fastener selection. An increasingly large part of his work, however, involves testing as part of longer term projects which aim to continuously improve the performance and quality of EJOT fasteners.

“The long term objective for developing my role at EJOT UK is to ensure that we are offering the highest possible technical service to customers,” said Jon. “Whether it’s through specification, testing or training, our goal is not only to maintain our position but to push fastening technology and services to new levels of engineering and science. What is key for me is to always be looking at how best to make complex and relevant technical data easy to understand and accessible to everyone.”

Applying metallurgical expertise to benefit EJOT customers

Jon’s role at EJOT includes ensuring the company’s technical literature and testing procedures are aligned with modern engineering standards and provisions. In addition, his work is important to influence new projects as well as influencing the overall direction of projects being undertaken in the UK.

His interest in metallurgy, supported by the knowledge he has amassed relating to metals, is important in helping customers achieve the strongest, most reliable joining of two materials.

“Before we consider the strength of a fastener, we have to understand metals,” explains Jon. “Whilst steel and aluminium alloys used in construction are very well controlled and documented in terms of production and maintenance of minimum strength properties, continuous testing is essential to check for variability.”

The Applitec team have seen many times how metals greatly exceed the minimum strength classification, falsely alluding to enhanced withdrawal resistance.

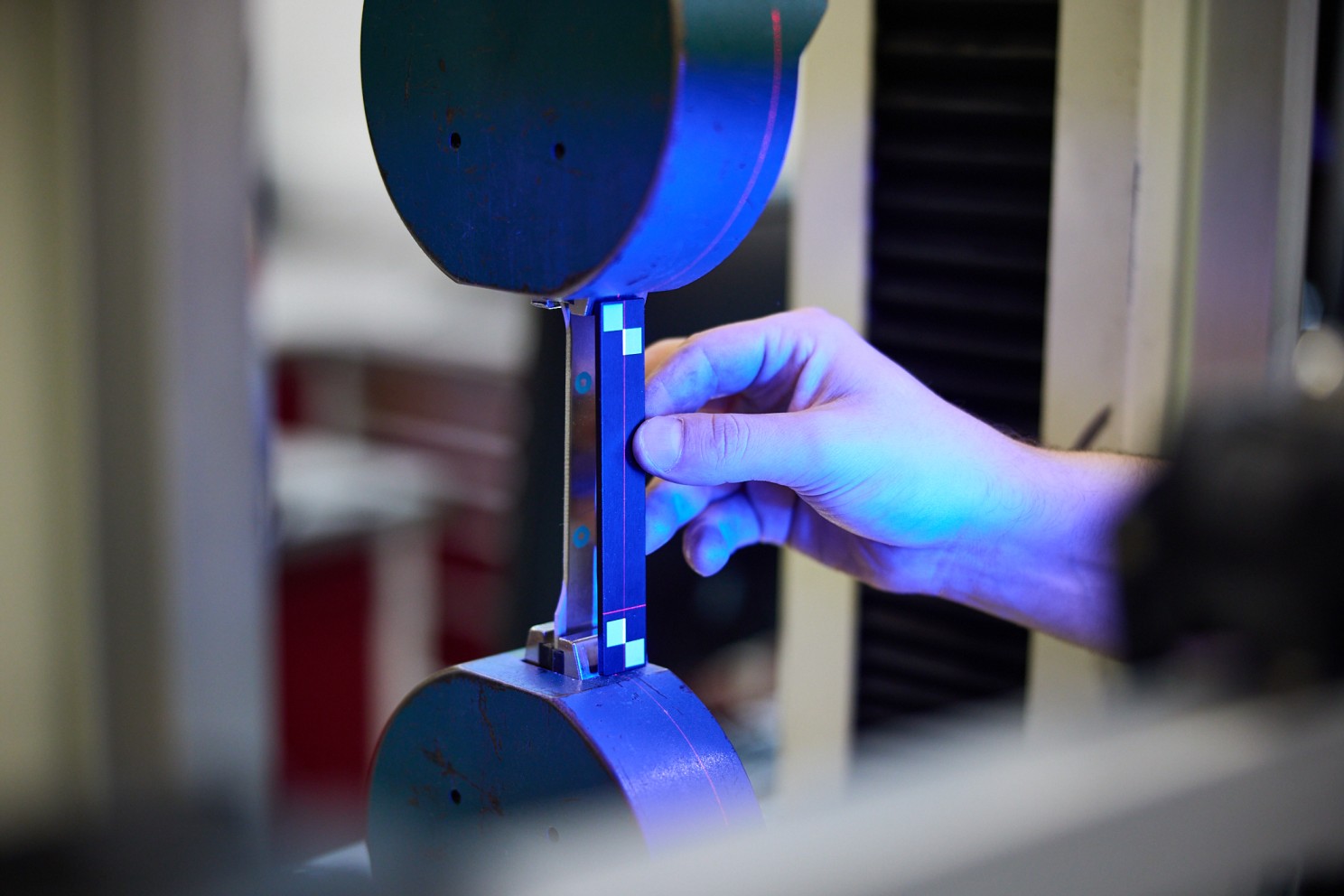

Despite there being very well established International Provisions, such as ENs, ASTMs and AS/NZS relating to the strength characteristics of steels and aluminiums, EJOT’s Applitec Centre has been equipped with world-class equipment to ensure the team can do its own materials tensile testing. The laboratory environment that has been created enables the team to comprehensively check that EJOT fasteners will perform better than the calculations provided within Eurocodes.

Comprehensive testing to validate performance

Jon and his colleagues conduct a variety of tests to check the performance of fixings into different substrates. These are chiefly perform pull-out or withdrawal testing, pull-over testing, shear testing, and also cyclic fatigue testing.

Jon continues: “With a shear test, there are two pieces of metal that we are connecting. So, we must check both to know the thickness and the strength. After that we can then conduct a pull out test.

“To conduct the shear test, we fix the two metals together, load them into our extensometer and pull them apart. But because we’ve gone to such lengths to assess the metal characteristics beforehand, the results from the shear test are extremely reliable.”

Confirming the strength of metals is one of the ways EJOT takes a holistic approach to providing evidence of the fastener’s performance and expanding on what is stated in an ETA.

Jon adds: “An ETA will never be able to cover every application, so it is common for customers to ask, ‘will this fastener work in this situation?’ – and that is something that our team will always seek to answer through our experience and test data.”

The EJOT Applitec Centre facilitates in-depth testing thanks to the range of advanced machines it houses, all purpose-designed to conduct testing of fasteners to a high degree of accuracy. This includes being able to determine the thickness of the coating on galvanised sections, which is a crucial factor in characterising the mechanical performance of fastenings, using a laboratory grade XRF (X-Ray fluorescence) machine.

Delivering unrivalled customer support

One of the key reasons why Jon and the team can provide such detailed reports to customers is due to the quality of the equipment available within the Applitec Centre. This is central to EJOT UK’s strategy to continuously invest in the tools the technical team needs to do their work to industry-leading standards.

For example, the team can test the exact level of stress versus strain in materials, a process which also measures the brittleness and ductility of materials. They can also conduct accelerated environmental testing to evaluate how well the fastener will perform in-situ throughout its lifetime.

And cyclic fatigue and pullover testing is also conducted, as is measuring installation torque. This is a significant area of testing as Jon explains:

“We can measure the installation torque – the clamp load – to a seriously high degree of accuracy. This is valuable data when defining relationships between torque and clamp force and establishing a coefficient of friction, which can be of value when researching new coatings and new ways of applying coatings. This can help to ensure that the installer’s experience of using our fasteners is maintained, for example.”

Supporting the complete roofing and cladding supply chain

While larger systems manufacturers may have in-house testing resources, many stakeholders in the building envelope supply chain do not. That means EJOT offers a service to help architects, structural engineers and contractors meet performance targets and deliver high quality buildings.

Jon concludes: “The facilities that we've got here are laboratory grade. We can do really intricate technical work to very high standards because we've got the kit through the investments that have been made by EJOT over many years. It's not just been an overnight exercise, the vision was there from an early stage for us to have a world class laboratory, and that’s what we've achieved. But this is by no means the end to the Applitec Centre’s development – it is continuously evolving.

“Technology has always been at the forefront of what we do at EJOT and the Applitec team will always look at ways we can apply even more advanced laboratory apparatus and to strive for even greater technical excellence from our team.”

https://www.ejot.co.uk/Appliance_of_science

How EJOT UK’s materials science expertise is raising the bar on fastener performance

Image Gallery

Jon Knaggs, EJOT UK’s Technical Manager, whose role involves applying materials science knowledge to the testing of fasteners for construction projects.

The EJOT UK Applitec Centre is equipped to be able to conduct accelerated environmental testing to evaluate how well the fastener will perform in-situ throughout its lifetime.

| T | (01977) 687 040 |

|---|---|

| F | (01977) 687 041 |

| E | infouk@ejot.com |

| W | Visit EJOT UK Ltd's website |

| Hurricane Close, Sherburn Enterprise Park, Sherburn-in-Elmet, Leeds, West Yorkshire, LS25 6PB |

Categories

Fixings and fasteners