When it comes to underfloor heating, preparation is the key to success. RWC’s Richard Bateman – Product Marketing Manager for Plumbing and Heating – explores some of the key considerations that will enable installers to get the most out of every installation.

Underfloor heating (UFH) is growing in popularity right across the UK, driven by ambitions to improve the sustainability and cost-effectiveness of home heating. Its versatility means that systems are just as comfortable serving a new build property as they are an older home undergoing renovation, making for easy adoption of sustainable home heating.

To make sure every system is installed to deliver to the highest standards, installers will need to consider various factors on every project – from the type of floor they are dealing with through to the location of the manifold.

To ensure efficient installation and optimal performance, let’s take a look at the key considerations shaping the installation of underfloor heating.

Starting at the source

Much like traditional heating systems, UFH can be easily adopted in properties of all shapes, sizes and ages. Part of this flexibility is a result of its ability to be integrated with several heat sources, including traditional gas boilers and modern heat pumps. When embarking on a new project, installers should first check the property’s heat source, as this will be key in maximising the potential of new UFH.

Running at considerably lower temperatures than radiators – typically around 35-45°C rather than 65-70°C – UFH can be up to 25% more efficient. This lower operating temperature makes UFH particularly suited to a system that utilises a heat pump as its primary source, further strengthening sustainability credentials. Even in properties where heat pumps aren’t installed, UFH can be paired with a standard boiler – although this may limit efficiency gains.

As UFH continues to emerge as the modern choice for smarter home heating, regardless of the chosen heat source, the shift away from traditional central heating systems in favour of underfloor heating promises improved efficiency and sustainability.

Location, location, location

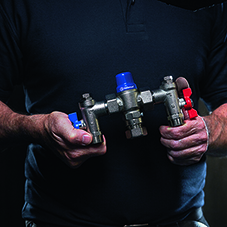

In addition to selecting the appropriate heat source, installing an effective UFH system requires carefully planning the location of the manifold. The manifold is the heart of an UFH system and connects the pipework to the heat source, ensures accurate water temperature, pressure and flow, and effectively distributes warm water to each UFH zone.

The position of the heating manifold is critical to ensuring effective operation. As well as informing the pipe layout in each zone, its location can impact overall system efficiency. By placing the manifold in a central location, temperatures can be maintained for optimum efficiency, while also making it straightforward to connect pipework across different zones.

Pipe runs must be of the correct length to cover the entire floor space and have the appropriate spacing – the general rule of thumb is 200mm for a standard and 150mm for a low-profile underfloor system. This ensures the system delivers effective heating with minimal heat loss.

Floor types

Besides the installation specifics of UFH, it is just as important for installers to consider the floor finish that the system will be hidden beneath. From carpets and laminate through to timber and ceramic tiles, there are an array of floor finishes available – and while they’re all compatible with UFH, some are more effective than others.

Heat transfer is an important consideration in any UFH installation. Each material conducts heat differently, and depending on the chosen floor finishing, the overall efficiency of the UFH system may differ. Installers may also need to make small tweaks to system operation to accommodate materials with differing levels of conductivity.

Ceramic tiles offer the best levels of heat conductivity, meaning heat will transfer more quickly and efficiently from the network of pipes into each zone. Similarly, timber floors – including engineered timber – effectively support the transfer of heat, making them a desirable finish. At the opposite end of the scale is carpet and, while it is compatible with UFH, it will take longer for heat to transfer into a space due to its higher tog value. To ensure UFH can still work well with a carpeted floor, it is recommended that the combined tog value of the carpet and underlay doesn’t exceed 2.5.

An installer’s guide to UFH

For both seasoned installers and newcomers to the world of underfloor heating, the range of considerations to make at the installation stage can be overwhelming. To help installers navigate these challenges and make a success of every UFH installation, a brand-new eGuide is available from RWC – the brand behind JG Underfloor.

Covering the ins and outs of UFH, from sizing and installation through to finishing and maintenance, the eGuide helps installers to achieve accurate and seamless installations every time.

Download your free eGuide here: johnguest.com/ufh-e-guide

Installation considerations: how to get the most out of underfloor heating

| T | (01895) 425333 |

|---|---|

| E | Info@RWC.com |

| W | Visit RWC – Reliance Worldwide Corporation's website |

| Horton Road, West Drayton, Middlesex, UB7 8JL |

Categories

Underfloor heating

(002)-comp104848.png)