Client: J&J Stanley, Newcastle upon Tyne.

Type of works: Utilisation of all water management processes to create a value-engineered SUDS scheme for new handling yard.

ACO Water Management’s ability to supply products that cover every process required for sustainable drainage – Collect, Clean, Hold, Release - has delivered a comprehensive, value–engineered SUDS solution for J&J Stanley at its new waste transfer station in Newcastle upon Tyne. By working with a single team on the design of the entire system, the completed scheme – together with each individual stage within it - is not only optimised to the unique hydraulic conditions at the site but also considers where costs can be minimised across every aspect of project.

Conceived originally as a point gully system, the main contractor for the project, G&B Civil Engineering Ltd, approached specialist civils merchant, Burdens Limited, to supply materials.

“As discussions developed with G&B, we realised that with a fresh approach to the design of the drainage system some significant, wider benefits could be realised across the rest of the project,” says John Copping at Burdens’ Stockton branch.

“We knew through our longstanding relationship with ACO that its Design Services Team would be able to provide a detailed analysis of the site and develop an integrated SUDS scheme that would take advantage of the latest cost-saving water management technologies.”

The catchment at the site is a new concrete pavement 200 metres long and 20 metres wide with a permissible discharge to the local storm sewer of just 5 litres/sec. Through consultation with J&J Stanley, ACO’s team recognised that the operating conditions at the site – where a degree of standing water for a period of time was acceptable – would allow a higher degree of design flexibility and considerable scope to reduce costs.

“By understanding how the site operates, we were able to value-engineer the surface water attenuation characteristics of the entire system,” says Stuart Lindsey at ACO Design Services. “As we have the capability to supply every component in the system, a complete surface-to-outlet design approach could be adopted. By doing this, both the contractor and client gain maximum benefit. The system is quicker and easier to install as it is shallower and requires less ground infrastructure; the structure and layout of the concrete pavement is simplified; and the ongoing operational and maintenance costs are greatly reduced.”

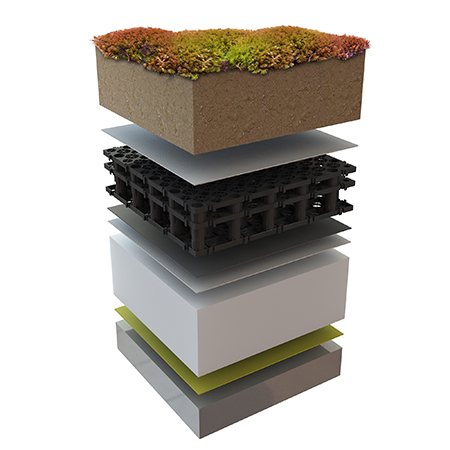

Stable and fully watertight The original point gully scheme has been replaced by a single 140 metre run of ACO Qmax 350 channel. The attenuation provided by the Qmax is matched with that of a 60 cubic metre ACO StormTank which is installed downstream. Encased in an impermeable geomembrane which is then wrapped in a protective outer fleece, the StormTank is stable and fully watertight.

Between the collection channel and the tank sits the largest capacity unit in ACO’s new range of Q-Ceptor bypass oil separators. The ACO Q-Ceptor prevents any run-off contaminated with petrol, diesel or oil on the concrete pavement from entering the storm sewer network. The unit is robust and compact having a unique, vertically configured single treatment chamber that is designed to extend filtration performance, ease access and reduce the separators’ overall footprint – a feature that significantly lowers installation cost.

Discharge of cleaned surface water from the StormTank into the sewer is restricted to the maximum 5 litres/sec by an ACO Q-Brake Vortex vortex flow controller. Exploiting the hydraulic characteristics of a forced vortex, the Q-Brake Vortex has no moving parts. This allows an outlet cross section 4-6 times larger than traditional flow controllers, making it less prone to blockage, easier to maintain and, by permitting higher flows at lower head pressures.

It also significantly reduces stormwater storage volume requirements, allowing up to a 10% cost saving in upstream infrastructure.

View StormBrixx Attenuation & treatment of Stormwater control Product Entry