Underfloor heating is increasingly being seen as a viable, future-proof alternative to conventional heating methods. In response to this shift, RWC's Richard Bateman – Product Marketing Manager for Plumbing and Heating – highlights the importance of integrating high-quality and efficient products from the beginning of the installation process. This proactive approach not only future-proofs underfloor heating systems but also serves as a preventative measure for future maintenance needs.

The adoption of green solutions is accelerating at an unprecedented rate. In the first half of 2023, more than 120,000 green technologies – from heat pumps through to solar panels – were installed in UK homes, according to the Microgeneration Certification Scheme (MCS) . This significant growth is reflective of the appetite amongst homeowners to transition to more efficient solutions – and the potential growth that could be coming down the road for installers.

The increased demand for sustainable technologies also extends to underfloor heating (UFH), which is transforming home heating and supporting the reduction in household emissions. As systems become more commonplace, installers will begin to see an upturn in maintenance of these systems, ensuring their long-term performance.

Let’s take a look at some of the key considerations for maintaining effective underfloor heating performance.

Setting the foundation with quality components

The importance of quality components extends far beyond the point of installation. While the initial choice informs the system’s lifespan, significantly impacting its efficiency, effectiveness, and resilience, it also establishes the basis for its enduring performance.

Choosing high-quality products speeds up the installation process, as the right products are designed for seamless integration and compatibility. The installation process is streamlined by the components' precise fit and dependable performance, reducing any potential delays. Shorter completion times are one of the immediate advantages of a smoother installation, which enables projects to advance on schedule.

By prioritising quality from the outset, the stage is set for a reliable and efficient UFH system that continues to deliver consistent warmth and value over the long term.

Central to the installation process is the consideration of pipework – a task where the choice of high-quality materials takes precedence. Opting for pipes that complement UFH installations can significantly influence the efficiency and durability of the system. A prime example is the JG Layflat pipe offered by JG Speedfit, which is designed to lie flat and flexibly navigate corners while forming pipe circuits. As well as speeding up installation without compromising quality, the use of JG Layflat can also reduce the number of connections required and ultimately strengthen the installation overall.

In essence, placing an emphasis on high-quality components and incorporating protective measures highlights a commitment to a smooth installation process and the sustained efficiency and durability of the system.

Navigating maintenance

All heating options require some degree of maintenance, both to preserve their longevity and ensure their continued effectiveness. Just as annual servicing is typical with boilers, there are several maintenance obligations when it comes to keeping underfloor heating operating smoothly and efficiently.

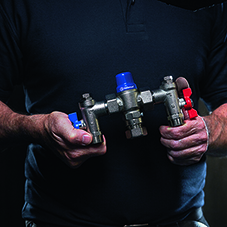

As an integral part of a yearly servicing routine, the whole system should be flushed and cleaned to ensure consistent and enduring performance. This includes the servicing of the mixing valve – involving cleaning, regreasing, and recommissioning as necessary – as this component is susceptible to debris accumulation that can impair performance. Additionally, air purging is vital during these annual inspections.

Although the maintenance needs of UFH are comparable to those of radiators in terms of regularity, the lifespan of well-maintained systems should exceed that of radiators. At the same time, UFH systems will deliver greater levels of comfort, performance and efficiency.

Choosing a manufacturer you can trust

When taking on a UFH project, choosing the solutions and support of a trusted manufacturer is paramount to the success and longevity of the system. Trusted manufacturers adhere to rigorous quality and testing standards in the production of their UFH components. This commitment to quality ensures that the materials used are durable, reliable, and designed for seamless integration, underpinning long-term performance.

Guiding installers through every stage of the process, from system selection through to maintenance, a brand-new free e-guide from RWC – the brand behind JG Underfloor – puts the practical insight from a leading manufacturer into the hands of professionals. When put into practice, UFH installations are strengthened, and their maintenance can be streamlined to deliver the very best results.

Download your free e-guide at johnguest.com/ufh-e-guide

Managing maintenance: underfloor heating need-to-knows

| T | (01895) 425333 |

|---|---|

| E | Info@RWC.com |

| W | Visit RWC – Reliance Worldwide Corporation's website |

| Horton Road, West Drayton, Middlesex, UB7 8JL |

(002)-comp104848.png)