Mesh.covering

Aliva UK

Aliva’s expanded and perforated aluminium facade suite offers unparalleled customisation and creative possibilities, blending intricate patterns, intersections, and metallic weaves that allow designers to realise their vision like never before.

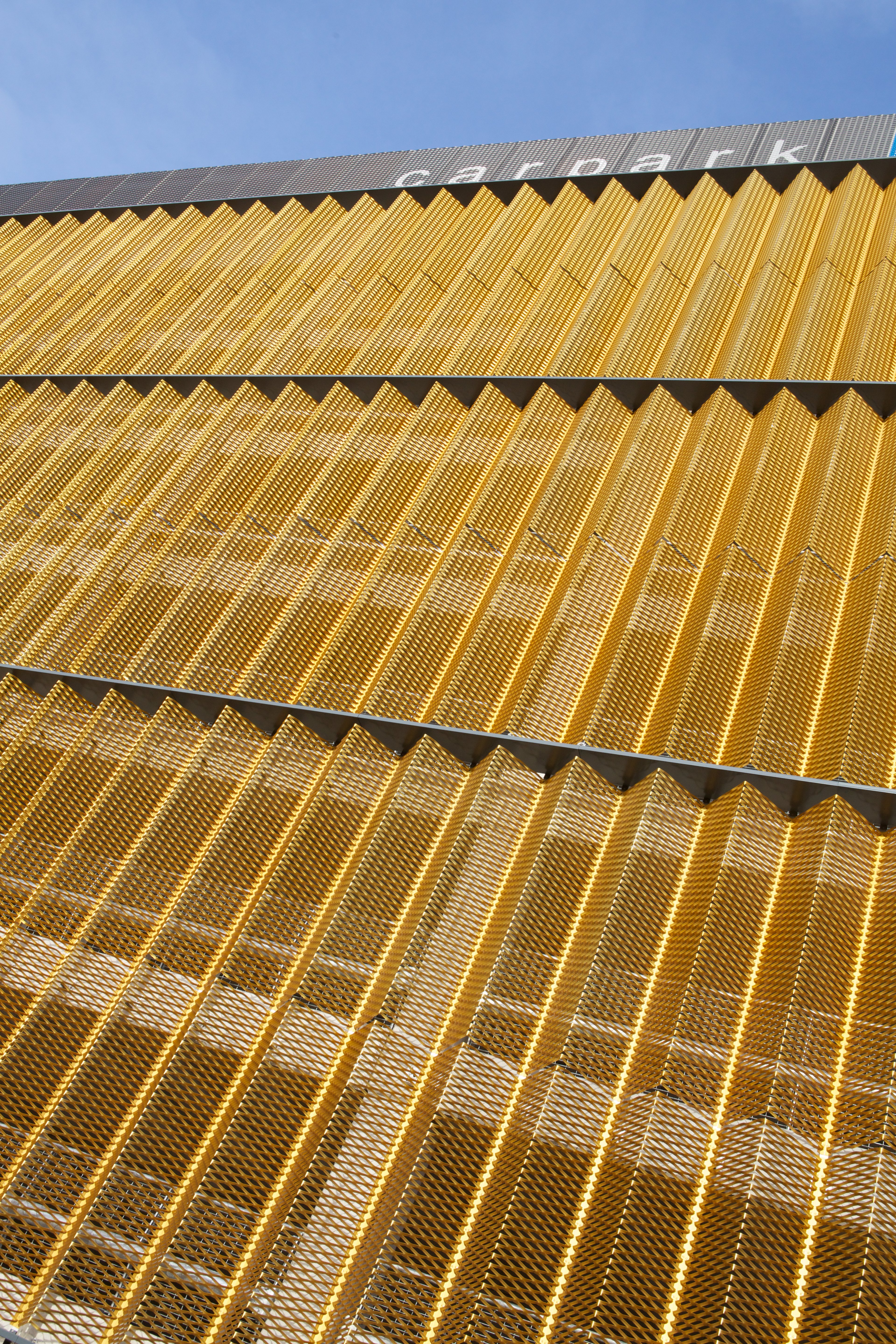

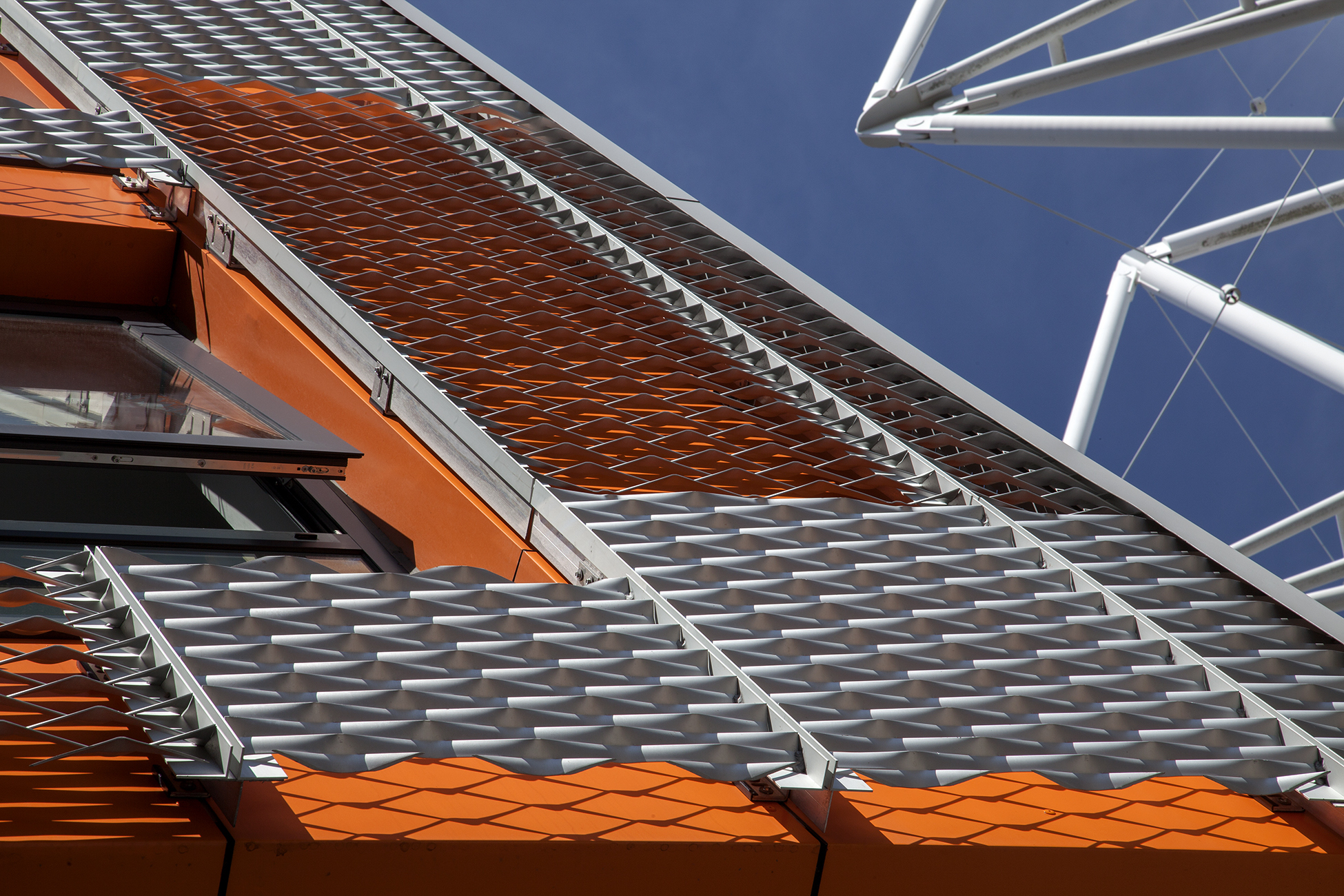

Our Mesh.covering creates captivating visual dynamics, with interactions between light/shadow or solid/void, creating a sense of both modularity and movement. Panels can be curved and shaped in multiple formats. Bold colour palettes are possible, alongside the incorporation of artwork, anodising, and other custom finishes that contribute to the dynamic character of perforated and expanded mesh solutions.

Our mesh product range offers a spectrum of finishes, from diamond and slotted patterns to circular, flat, shaped, rigid, flexible, shiny, matte, natural and coloured options, all fostering imaginative and artistic architectural expressions.

Our range of anodised meshes offer unrivalled options in terms of colour choice across the anodising spectrum. Whether your choice is vivid red, orange or yellow through to a bold blue or a luscious green, we can produce these colourways, all with an external performance warranty.

Aliva offers production from factories that incorporate both the mesh production and in-house anodising tanks within the same facility, offering both value and reduced production times for such bespoke and colourful finishes.

To ensure maximum durability, our mesh facades can be anodised or powder-coated, in line with architectural requirements. Along with the complete RAL colour range, we offer custom and special paints to give your project a unique finish.

Our anodised Mesh.covering is 100% non-combustible, achieving an A1 accreditation based on testing to standard EN 13501-1:2019. It is made of solid aluminium, does not release any toxic gases or create any fumes. Our Mesh.covering is also produced with pure aluminium alloy and is 100% recyclable.

Our PPC coated Mesh.covering cladding has also been certified as non-combustible with A2 classification in accordance with standard EN 13501-1.

Our cutting-edge production technology allows us to create various patterns within a single panel, including extra-large formats and we can manipulate the open strand dimensions of the mesh within a single pattern, producing a distinctive waveform effect on flat panels.

In addition to their striking appearance, mesh and perforated facades also provide significant practical benefits, including improved ventilation. The manufacturing process is highly efficient, with no material waste as the mesh is formed from a single piece of metal. This makes it more economical than punched metal, while maintaining exceptional strength and structural integrity, as there are no loose strands, strained joins or welds.

Aliva’s expanded and perforated mesh solutions are also sustainable. As with all our aluminium products, they are fully recyclable at the end of their life.