Terratoscana.covering

Aliva UK

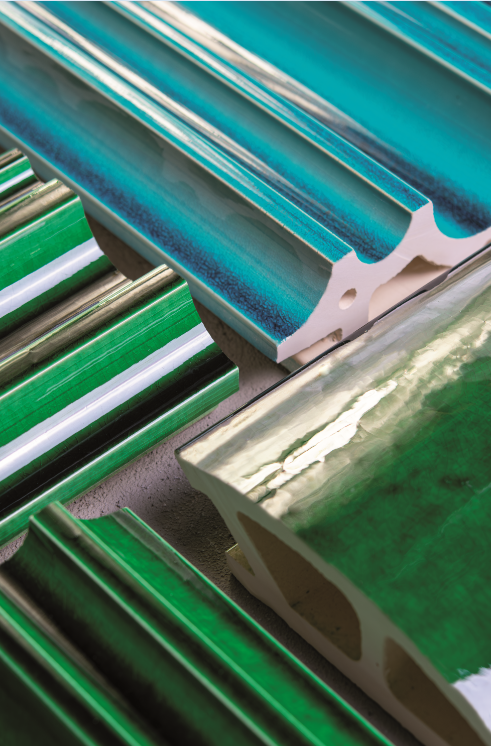

Our Terratoscana.covering represents Aliva’s ability to provide the most highly customised, handcrafted terracotta facade detailing, specialist glazes to meet designers’ dreams.

More than just an artisanal workshop, it is Aliva’s signature brand that marks a crossroads of tradition and innovation in clay, creating both a contemporary and timeless proposition.

Our A1 fire rated British Board of Agrément certified Terratoscana.covering represents Italian excellence that preserves and reinterprets the art of terracotta craftmanship from the renaissance-rich region of Tuscany.

Our terracotta master craftsmen combine generations of expertise handed down over time with visionary innovation, shaping bespoke creative solutions that inspire beauty while fully respecting the environment.

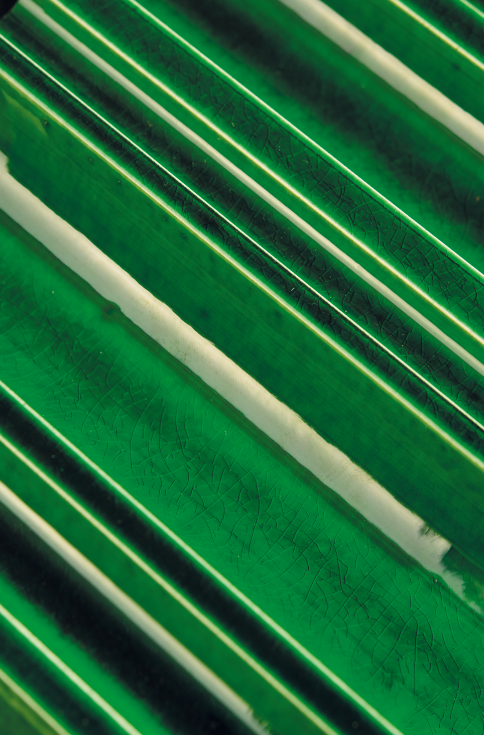

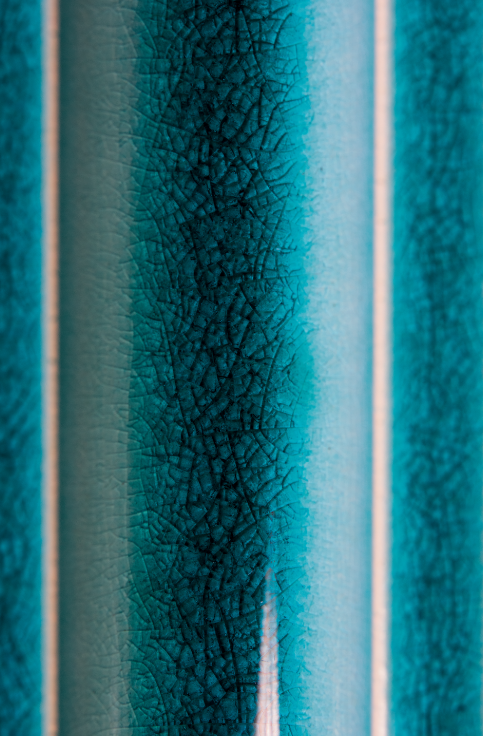

Terratoscana.covering sparks the imagination with our distinctive finishes, ranging from classic and rustic textures to contemporary, sophisticated finishes. Our range of surface effects is virtually limitless, including natural, glazed, metallic, craquelé, pearlescent, textured, and decorative patterned finishes.

The process begins with high-quality fine-grain mixtures, composed of pure raw materials: carefully selected minerals, noble clays, and pigments that enhance both aesthetic and chromatic performance. Firing at temperatures exceeding 1000°C (1832°F) ensures a high degree of vitrification, significantly increasing the material’s mechanical strength and durability and minimising water absorption.

Architectural elements take shape through different production processes, chosen based on the project’s specifications, such as shape, volume, dimensions and the desired aesthetic outcome. Regardless of the manufacturing process chosen, every element is a unique and unrepeatable piece.

Depending on the requirements, terracotta is shaped using three main techniques extrusion, press moulding and casting.

Extrusion: The material takes shape with linearity and precision, as it is pushed through a mould called a die or matrix, which defines its two-dimensional profile. This process is ideal for producing continuous or three-dimensional cladding with dimensions up to 300 x 1,500mm. After forming, the surface can be enhanced with custom textures and details and finished in either a natural or glazed look.

Press moulding: Clay is pressed between two moulds with a force exceeding 75 tons, enabling the production of flat or three-dimensional elements up to 600 x 600mm in size and 20cm in depth. This process is ideal for ceramic blocks used in artistic or design applications, both indoors and outdoors, and can be customized with natural or glazed finishes.

Casting: For more complex and sculptural forms, slip technique uses plaster moulds into which slip, a liquid clay suspension is poured. It allows for the creation of intricate geometries, undercut sections, thin walls, and refined details, without dimensional limitations. Ideal for custom architectural and design elements with high expressive value, the resulting surfaces can be hand-finished and refined with glazes or natural finishes.