With innovative copper heat sinks, high-heat-dissipation hermetic packages give laser manufacturers a competitive edge by providing reliable, efficient, and flexible solutions.

SCHOTT’s new high-heat-dissipation TO-9 and SMD-based copper packages provide the thermal management necessary for high-power laser diodes to maintain beam performance and longevity.

Featuring copper heat sinks, these hermetic packaging components dissipate heat more efficiently than stainless steel or alloy headers.

The customizable components are ideal for laser systems used in industrial, medical, automotive, and consumer electronics applications.

SCHOTT, a leading developer and manufacturer of advanced electronic packaging solutions, announced the commercial availability of its next-generation high-heat-dissipation TO-9 and SMD-based copper packages. These cutting-edge components are designed to meet the growing thermal management challenges posed by high-power laser diodes.

SCHOTT will showcase these products during SPIE Photonics West from January 20 to 22, 2026 at Booth 1341 in the Moscone Center, San Francisco, California.

Solving high-power laser challenges

As laser power densities continue to increase, effective heat dissipation has become critical for maintaining laser beam performance and longevity. SCHOTT’s new hermetic packaging components with copper heat sinks deliver an exceptional thermal path, outperforming conventional stainless steel or alloy headers by dissipating heat significantly more efficiently.

The components are designed for laser system manufacturers in industrial, medical, automotive, and consumer electronics sectors, with typical applications including laser cutting and welding, aesthetic treatments and surgical procedures, head-up displays (HUDs), and advanced digital projection systems.

TO-9 platform: cost-effective, high-performance alternative to box packages

SCHOTT’s high-heat dissipation TO-9 transistor outline header offers a compelling replacement for traditional box packages. Its unique through-hole copper heat sink design delivers superior thermal performance, supporting excellent color and beam quality. SCHOTT's precision manufacturing ensures surface flatness, enabling stable laser output power and longevity — key requirements for high-power laser systems. These features make SCHOTT’s TO-9 an attractive option for manufacturers seeking to reduce costs without compromising performance.

Trusted development partner

"Our high-heat-dissipation TO-9 transistor outline headers are more than just components; they are a strategic enabler for our customers," said William Ong, product group head at SCHOTT. " By addressing thermal management effectively, we help laser manufacturers build smaller, more powerful and reliable systems. We are committed to being a true development partner, helping customers capture market share and drive innovation."

Flexible design options

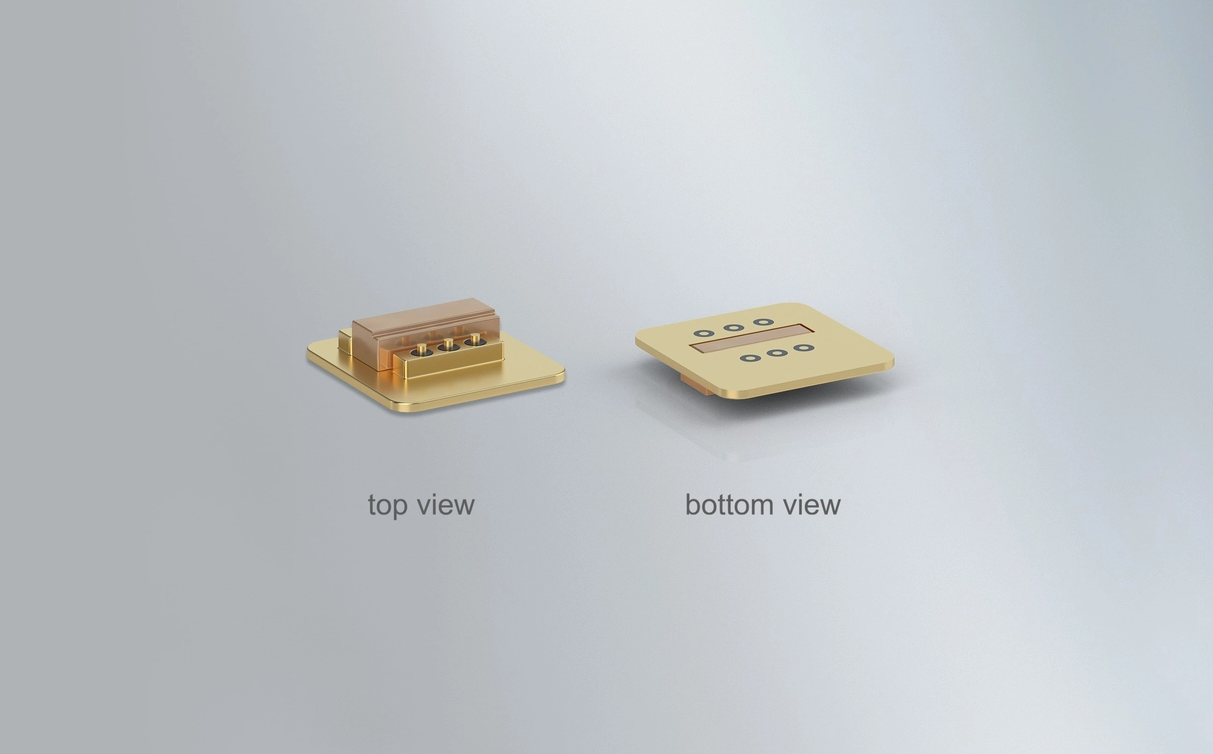

SCHOTT packages deliver exceptional heat dissipation performance in various form factors. In addition to TO-9 headers, SCHOTT offers SMD-based designs featuring full copper heat sinks.

With customization capabilities across the entire portfolio, SCHOTT can meet diverse customer requirements.

For more information, please visit the product website.

In addition to the new TO-9 transistor outline headers, SCHOTT will present a broad portfolio of specialty glass solutions, including flexible imaging bundles, BOROFLOAT®, ZERODUR® glass-ceramic, assembled protective windows, as well as other high-performance and optical materials. These cutting-edge solutions are made to enable industries such as consumer, automotive, medical, defense and other industrial applications.

Optimize high-power laser performance with advanced thermal management technology

Image Gallery

| T | +44 (0) 3300 021340 |

|---|---|

| E | info.uk@schott.com |

| W | Visit SCHOTT UK's website |

| Wolverhampton Science Park, Glaisher Drive, Wolverhampton, WV10 9RU |

Products by this Company