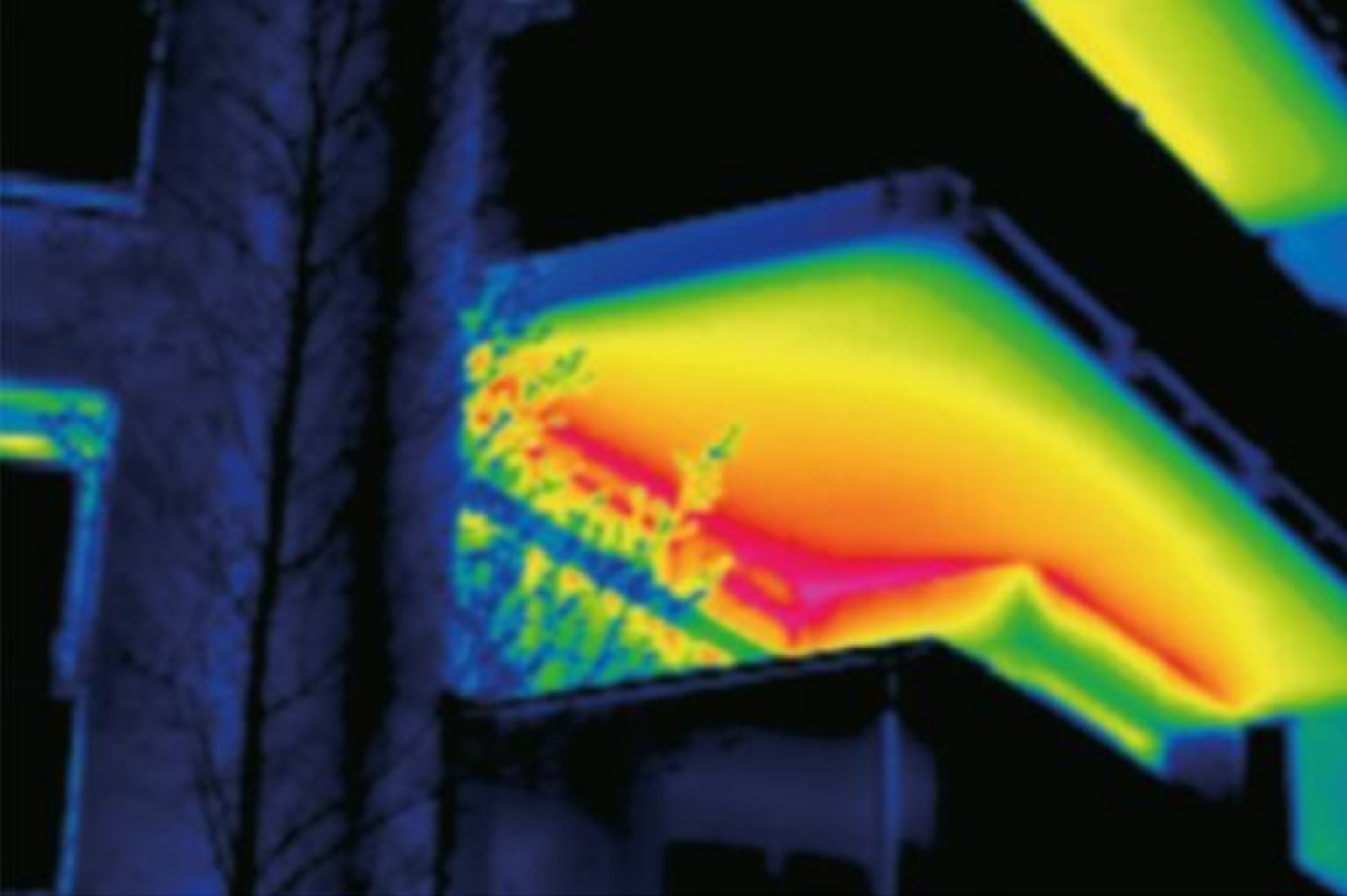

With changes to Part L of the Building Regulations having come into force on 15th June, 2022, CO2 emissions are now reduced by 31% for dwellings and 27% for other buildings. So improving the thermal performance of building envelopes is even more critical. Designers need to be aware of how significantly insulation values can be compromised by thermal bridges, which occur in a localised area of the building envelope – typically where a material with high thermal conductivity penetrates the insulation layer. Critical examples are cantilevered balconies, which result in higher heat transfer through the building assembly and colder surface temperatures on the warm side. The main consequences being non-compliance with regulations, condensation leading to mould growth and higher energy consumption for heating. The 2021 edition of Part L (which replaces L1A 2013) sets out the minimum thermal requirements for avoiding such issues.

Important new requirements

Thermal bridging must now be included in fabric heat loss calculations and the Standard Assessment Procedure calculation (updated to SAP 10.2) includes the term HTB (heat loss due to thermal bridging). A further change is that for new dwellings, an on-site audit must confirm that the details shown in the original design have been constructed, before they are concealed by subsequent work. Photographic verification must show that the products used are those in the original design. If there are substitutions, the revised specification should be reflected in the SAP calculation and included in the Building Regulations England Part L compliance report (BREL report). The revised Part L also includes general tightening of U-values, requiring greater insulation requirements and better performing thermal break details. Additionally, it encourages HTB assessment to be carried out through thermal calculation for a more realistic evaluation of existing thermal junctions. The default y-value has been increased to 0.20 W/(m2.K) to discourage generic estimations.

Thermal performance and structural integrity

Designers do need to be fully aware of just how significantly thermal bridges compromise insulation and the most effective way to minimise thermal bridging at cantilever balcony detailing is to incorporate a Schöck structural thermal break. This is a highly efficient balcony connector that minimises the flow of thermal energy between the interior and exterior of a building, providing both structural integrity and thermal isolation of the balcony. The Schöck range of thermal break solutions is for applications as diverse as concrete-to-concrete; concrete-to-steel; steel-to-steel; renovation projects – and even Passivhaus.

Condensation and mould growth

With thermal bridging cold surfaces can form condensation, resulting in structural damage – and of even bigger concern – mould growth. To identify areas where there is a risk of condensation and therefore mould growth, a ‘surface temperature factor’ (fRsi) should be used. It allows surveys under any thermal conditions and compares the temperature drop across the building fabric with the total temperature drop between the inside and outside air. The recommended (fRsi) value for offices and retail premises is equal to or greater than 0.5; and to ensure higher standards for occupants in residential buildings, equal to or greater than 0.75.

Contact Schöck on 01865 290 890; or visit the website at www.schoeck.com for a full introduction to the extensive range of product solutions.

Revised Part L and improved thermal performance with Schöck

| T | (01865) 290 890 |

|---|---|

| F | (01865) 290899 |

| E | design-uk@schoeck.com |

| W | Visit Schöck's website |

| Staniford House, 4 Wedgwood Road, Bicester, Oxfordshire, OX26 4UL |

resized-comp212922.jpg)