Water safety is paramount for domestic, commercial and public buildings in the UK, and installers, architects, contractors and specifiers all have a duty of care when it comes to planning new builds. In this blog, RWC discusses the importance of TMVs and how they safeguard the end-users.

Thermostatic Mixing Valves (TMVs) are fast becoming a crucial part of health and safety management for both domestic and commercial buildings – not only do they help prevent people from getting scalded, they also reduce the risk of water-borne diseases such as Legionnaires’.

Why are TMVs so important?

TMVs are crucial because they allow hot water to be stored at a constant high temperature to prevent Legionella bacteria from breeding in the systems, while ensuring safe water temperature from outlet to prevent scalding injuries.

The key to avoiding Legionnaires’ disease is to kill the bacteria in water supplies themselves. Water needs to be stored above 60°C in domestic and above 70°C in commercial, healthcare and public buildings to kill Legionella, however these temperatures are hot enough to cause scalding.

To resolve these concerns, TMVs are installed before the water outlet so that the hot water system can run at a higher disinfection temperature and can be blended with cold water at the point of use to a pre-set safe temperature. Alongside this, TMVs are also responsible for ensuring a safe outlet temperature even when water pressure fluctuates due to the simultaneous use of other appliances.

To protect end-users from the risks associated with the use of hot water, in 2012, TMVs were made a legal requirement for all commercial and domestic new builds or properties undergoing a ‘change of use’. This was done to overcome the challenge of balancing water at a high temperature to prevent Legionnaires’ disease whilst avoiding scalding.

How does a TMV work?

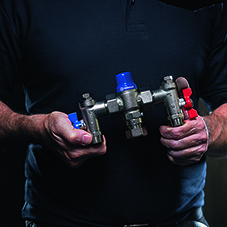

TMVs use an internal thermostat that automatically blends hot and cold water to achieve safe water temperature from outlet. All TMVs from Reliance Valves feature a rapid failsafe mechanism to shut off the water supply to outlet, in case either hot or cold supplies are cut off/interrupted.

Choosing the right TMV

There are several TMVs to choose from – but the key to a successful installation is understanding the application first. This is because domestic, commercial and public buildings have different requirements to healthcare buildings.

TMVs for domestic, commercial and public buildings

Domestic, commercial and public buildings must use TMV2 certified valves – formerly known as the BuildCert scheme. Under this scheme TMVs are required to maintain a safe and stable temperature of under 48°C at all times and quickly shut off in the event of hot or cold-water failure. TMV2 certified valves also need to be annually tested in commercial applications. The certification is invalid if this test is not conducted every year.

All of RWC’s TMV2 certified valves, such as the Easifit® and Ausimix® come complete with either 2-in-1 fittings that include check valves and strainers, or 4-in-1 fittings which in addition incorporate isolators and test ports. This allows the water supply to be shut off for that TMV only. The parts of the valve that need testing and servicing can be easily demounted, and then re-installed once the valve has been checked and cleaned, allowing the rest of the system to work as desired without interruption.

TMVs for healthcare buildings

Healthcare buildings, on the other hand, have more stringent regulations and must use TMV3 valves. This is because of the high number of vulnerable people in these buildings, such as children and the elderly. TMV3 valves have more rigorous testing processes with periodic checks six to eight weeks after installation. These checks include a thermal element endurance test, a hot spike test, a response on temperature adjustment check, a stability test and a fail stop valve check. If the valve isn’t checked within the required timeframe it will be marked as non-compliant and no longer suitable for use.

RWC’s range of TMV3 compliant valves include the Easifit®, Ausimix® and the Heatguard® Dual. An added feature on these valves are anti-tamper caps, which prevent any unwanted tampering that could occur because the TMVs are sometimes installed in places that can easily be accessed by the public.

TMVs are a step towards creating a safer built environment and they should be championed by both specifiers and installers to safeguard end-users from risks associated with hot water systems.

Find out more about their range of TMVs here.

Safety first with TMVs

| T | (01895) 425333 |

|---|---|

| E | Info@RWC.com |

| W | Visit RWC – Reliance Worldwide Corporation's website |

| Horton Road, West Drayton, Middlesex, UB7 8JL |

(002)-comp104848.png)