Agar Grove Estate, in North West London, is undergoing a six-phase major regeneration, due for completion in 2025.

It will deliver 493 new high-quality homes for existing residents, in what is claimed to be the largest Passivhaus development to date in the UK, and Camden Council’s largest community investment project.

The homes will be complete with maisonettes and gardens on the ground floor and apartments on the higher floors with full-width balconies

As the project is to Passivhaus standard, the development meets the most demanding levels of sustainability and energy efficiency. High levels of insulation to the thermal envelope mean exceptional levels of airtightness and a critical requirement here is the avoidance of thermal bridging, a frequent cause of increased heat and energy loss, condensation and possibly mould growth.

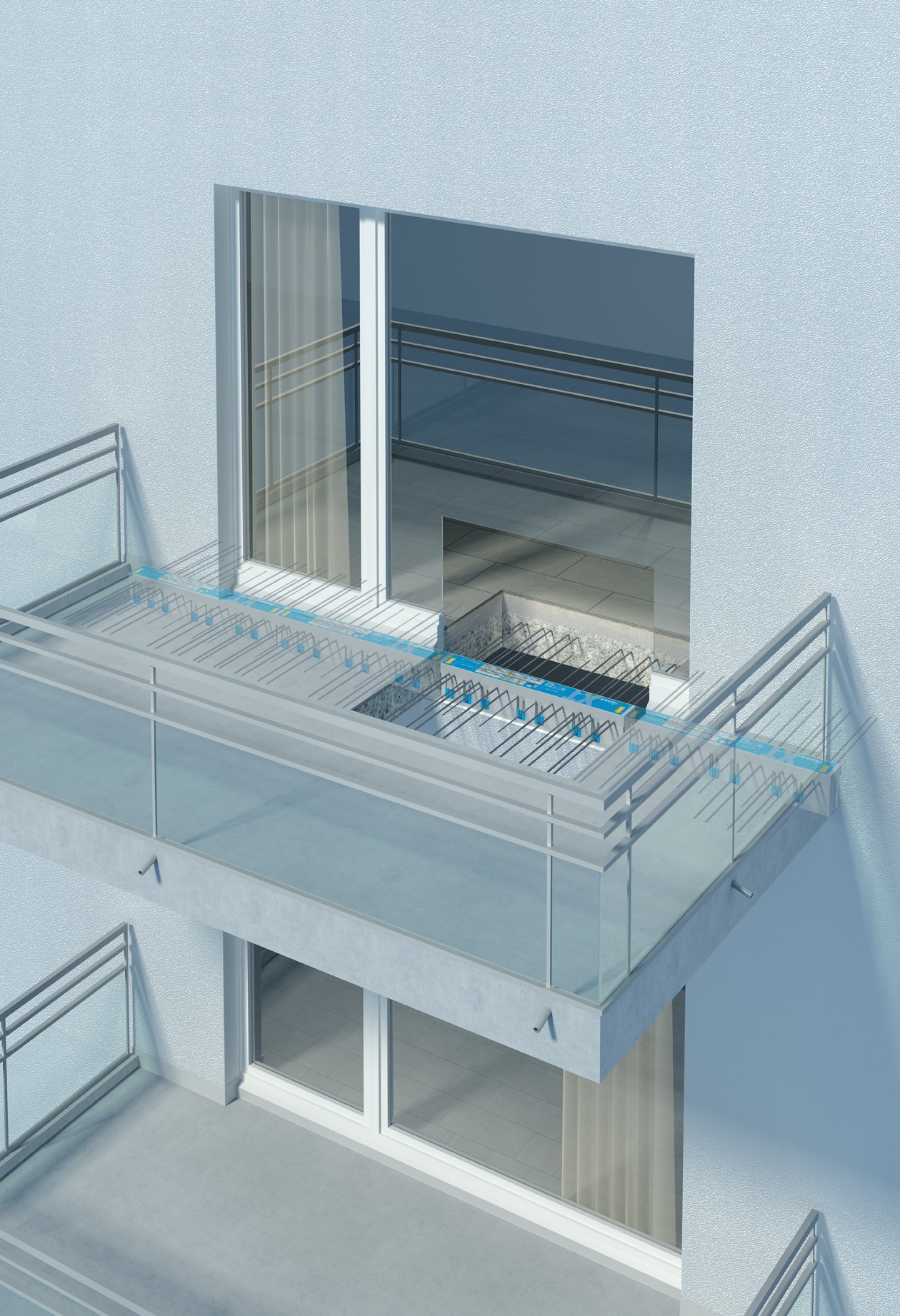

The Isokorb range of structural thermal breaks from Schöck has been used to counteract the possibility of thermal bridging at the places most vulnerable from it: balconies and parapets.

For the balconies, the Isokorb type used transfers both negative moments and positive shear forces. It has been awarded the "Low Thermal Bridge Construction" certificate by the Passivhaus Institute in Darmstadt, verifying its suitability for Passivhaus construction.

With parapets, the conventional insulation method is to wrap the perimeter of the wall with an insulation barrier – but with the Schöck Isokorb designed for parapets, there is no wrapping required It is more cost-effective and more thermally efficient than conventional wrapping and its 120mm insulation dramatically reduces heat loss.

There is no risk of any additional thermal bridging through balustrade fixings – and other key benefits are durability and water impermeability. The Isokorb does not require maintenance and there is no risk of expensive restoration due to waterproofing problems.

The Schöck product types used at Agar Grove are primarily for concrete-to-concrete connectivity and for wrapped parapets. But the comprehensive Isokorb range also offers solutions for concrete-to-steel and steel-to-steel situations.

When any Isokorb product type is incorporated into residential buildings, the required fRsi value – the temperature factor used to indicate condensation risk that must be equal to or greater than 0.75 – is always comfortably met.

Products meet full compliance with the relevant UK building regulations, have NHBC approval and offer LABC Registration. There is also the security of independent BBA Certification.

Schöck Isokorb for largest UK Passivhaus development

| T | (01865) 290 890 |

|---|---|

| F | (01865) 290899 |

| E | design@schoeck.co.uk |

| W | Visit Schöck's website |

| Staniford House, 4 Wedgwood Road, Bicester, Oxfordshire, OX26 4UL |

resized-comp212922.jpg)