The construction industry accounts for approximately 60% of materials used and one third of all waste generated in the UK, with concrete blocks making a significant contribution to the built environment. As a result of this, sustainability is fully integrated into the operations of Lignacite. The company’s commitment goes far beyond legislation, with voluntary action vital to making products and operations more sustainable.

Due to their inherent sustainable properties, concrete blocks will result in buildings that are strong, adaptable and have a long lifespan compared to other forms of construction.

Environmental Commitment

Lignacite ensures throughout their full range that manufacturing potential is maximised through the reuse of waste materials, thus minimising environmental impact and landfill usage.

The company responsibly source materials through the principles of BES 6001, as well as maintaining certification to the environmental standard ISO 14001. Raw materials are used efficiently through quality control practices that are overseen by a BSI certified ISO 9001 Quality Management System. Alongside this, Lignacite set and complete their own in-house environmental targets and objectives.

Improving and Monitoring Sustainability Performance

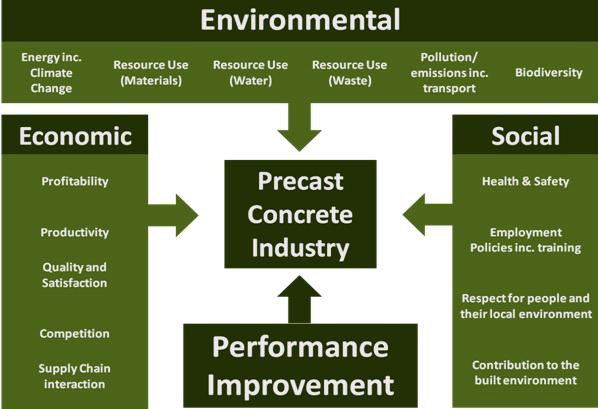

Lignacite is a signatory to the British Precast Concrete Federation ‘Sustainability Charter’. The aim of the Charter is to encourage members to go beyond legislation and voluntarily make their products and operations more sustainable.

In order to meet this aim, a set of sustainability principles have been developed based on the key sustainability issues facing the precast industry; these issues are shown in the second image of the carousel.

An important part of the commitment is to allow British Precast to audit member companies’ sites annually to ensure that all the 16 principles are being adhered to by member companies.

A recent milestone was the publishing of an Environment Product Declaration (EPD) for aggregate blocks. Data contributed by Lignacite led towards the EPD. The data is independently verified, and the registered document communicates transparent and comparable information about the life-cycle environmental impact of products.

All Lignacite concrete blocks are fully recyclable and will always almost certainly be recycled into aggregates for use as hard-core or piling mat at the demolition site or other construction sites.

Use of Recycled Raw Materials

Lignacite has a long history of using recycled and secondary aggregates in production. The original Lignacite block, first produced in 1947, used a proportion of graded wood particles as part of its constituents. This is still the case today.

Social, economic and environmental benefits can be attributed to the use of recycled and secondary aggregates (RSA), providing that the quality of the aggregates is fit for purpose and meets the published specifications. These benefits are not only conferred on the manufacturer but also society at large.

Examples of the use of RSAs by Lignacite include furnace bottom ash, crushed glass and graded wood particles, and they are continually investing in new technologies to allow more use of RSAs in their production.

Thermal Mass & Insulation

Due to the urgency brought by climate change predictions, it is appropriate to consider passive technologies that can be used in place of energy intensive air conditioning. Increasingly, design teams are incorporating thermal mass into their structures. All Lignacite products have the potential to prevent overheating and provide a more comfortable internal environment.

For many building types, including commercial buildings and dwellings, a more sustainable solution to combat the risk of overheating is to utilise high thermal mass elements together with night cooling. This approach, also known as fabric energy storage (FES), typically focuses on the building’s thermal mass optimised by using fair faced blockwork as well as exposed concrete floor slabs. The walls and floors absorb heat, helping to reduce overheating and ensuring a more stable internal temperature. Night-time cooling purges the stored heat from the walls and the slabs, preparing it for the next cycle.

The proposals to amend Part L Thermal Standards of the Building Regulations offers a real challenge to the construction industry. The Government has issued ‘The Future Homes Standard’ which sets out what a home built to the Future Homes Standard will be like. It is anticipated that by 2025 an average home built to it will have 75-80% less carbon emissions than one built to current energy efficiency requirements (Approved Document L 2013). A new home built to the Future Homes Standard might have a heat pump, triple glazing and standards for walls, floors and roofs that significantly limit any heat loss. The first step is to introduce improved measures before the end of 2020. This may include;

Option 1: 20% reduction in carbon emissions compared to the current standard for an average home. This could be delivered by very high fabric standards (typically with triple glazing and minimal heat loss from walls, ceilings and roofs).

Option 2: 31% reduction in carbon emissions compared to the current standard. This could be delivered based on the installation of carbon-saving technology such as photovoltaic (solar) panels and better fabric standards, though not as high as in option 1 (typically double not triple glazing).

Changes to current practice for building fabrics will be required, but masonry construction can be adapted relatively easily, with little or no change to current building practice. A bigger dilemma is the balance between higher fabric standards and homes’ ability to have adequate ventilation and built-in measures (including thermal mass) to combat the consequences of summertime overheating. The consultation finishes in March 2020 after which Lignacite will be publishing wall solutions capable of meeting the next generation of thermal standards.

Responsible Sourcing

Lignacite is certified to the Building Research Establishment (BRE) Framework Standard for the Responsible Sourcing of Construction Products – BES 6001.

This certification means that concrete masonry products supplied by Lignacite are responsibly sourced, to an independently verified standard that addresses the social, economic and environmental impacts across the entire supply chain.

Under the BES 6001 Framework Standard, Lignacite’s products have been assessed by looking at existing quality, environmental, health and safety management systems together with other important criteria including: greenhouse gas emissions, resource use, waste and water and life cycle assessment.

The certification also allows for traceability of the product to ensure all areas within the supply chain are operating to high standards.

As well as providing customers with confidence of ethical production and supply chains, it also allows them to score more credits under the materials section of the BREEAM and other environmental assessment schemes such as LEED, or Leadership in Energy and Environmental Design.

Using Lignacite Blocks

AshGP, Lignacite and Lignacrete blocks can be used to construct cavity separating walls meeting the requirements of Building Regulations as well as the requirements of a number of Robust Detail specifications. Solid separating walls can be built using Lignacrete blocks. A number of specifications are also available that are capable of achieving higher standards of sound insulation than those given in Approved Document E to the Building Regulations. These are generally in accordance with certain Robust Detail specifications and can be used to gain credits for improved sound insulation.

For further information on the products and services offered by Lignacite, please visit their website or call 01842 810678.

Sustainability – A manufacturers responsibility

Lignacite

View company profile| T | (01842) 810678 |

|---|---|

| 01842 810678 Tech Dept. | |

| F | (01842) 814602 |

| E | info@lignacite.co.uk |

| W | Visit Lignacite's website |

| Head Office, Norfolk House, High St, Brandon, Suffolk, IP27 0AX |