Novum Structures realise that their activities have the potential to impact the economic, environmental, and social well-being of the communities in which they operate. By recognising, addressing, and embracing these issues as a fundamental part of maintaining a sustainable business model, Novum is committed to working not just for today, but for the sake of future generations.

There are many considerations when looking at the construction industry and how they can cut down on our carbon emissions and promote a more sustainable future. Novum has looked into each stage of a building’s life cycle – including the design, materials, manufacturing, transportation, and construction of a project.

The design of a project is important; not only does it impact the aesthetics, but it also impacts how energy-efficient the final build is going to be. As a world-leader in ETFE, Novum is always keen to outline the benefits of the lightweight material when thinking of solutions to upcoming projects. As per ISO:14025, our membrane factory in Germany has an Environmental Product Declaration from 2017 onwards.

Whilst ETFE is not biodegradable, it is 100% recyclable. The properties of the material, encompassing its ability to remain unaffected by UV light, atmospheric pollution and adverse weathering, result in a long-life expectancy. EFTE is anticipated to withstand up to 100 years, and therefore the need for ETFE to be recycled is then minimised.

ETFE can absorb large amounts of transmitted infra-red light which can make it a great choice in improving the energy consumption of a building. Whilst Novum concede that the pillows must be inflated all the time, it is worth noting that a 10000m2 EFTE pillow structure takes the same amount of energy to keep inflated as a domestic lightbulb!

Originally, ETFE was commonly used in the horticulture industry as plant life and vegetation thrive under it. The high translucency and permeability of the material, which absorbs up to 95% light, lets in those all-important UV A rays which are essential to plant health as it helps them photosynthesise.

The manufacturing process of ETFE is also environmentally friendly. As outlined in the EDP ‘foil waste which cannot be reused directly passes through a second stage on a regeneration machine before also being reprocessed into foil.’ so no solvents are used in the water-based procedure of ETFE production. The anti-adhesive, smooth material also minimises the need for cleaning. Water is often able to clean away any dirt, but if not then a mild eco-friendly, PH-neutral detergent can be used. The properties of ETFE mean that it is naturally resistant to solvents and chemicals.

ETFE is an extremely lightweight material, and due to this, the supporting structure can also be more lightweight. Fewer materials are the used in a final project, resulting in fewer materials being fabricated and transported. Thus, a reduced carbon footprint.

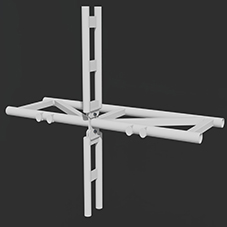

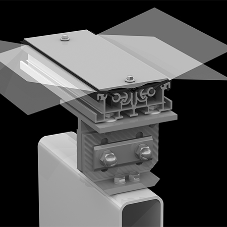

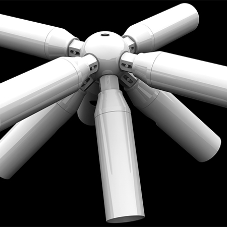

Regarding lightweight materials, Novum specifically encourages their lightweight nodal systems when the need for steel arises. This ensures that haulage is reduced, but also that the amount of packaging needed is drastically reduced as well.

Their steel fabrication facility in Turkey is strategically based near the port, ensuring that they can transport the steel across the sea easily. Novum consider all their deliveries, maximising storage and sequencing to minimise deliveries required. This is not only ecologically sound but also economically beneficial to both Novum and their clients.

Novum work with glass, steel, ETFE, and glulam and so a combination of systems is most commonly used in the design and build of their projects. ETFE is greatly complemented by glulam and timber frames. Many of their UK collaborations have used ETFE and glulam together, not only for the aesthetically pleasing and environmentally creative finish but for its reputation as a sustainable material. Much like ETFE, glulam can be reused or recycled, and the raw material is renewable. Glulam also boasts the lowest environmental impact for the greenhouse effect, acidification and eutrophication when compared to steel and concrete.

Novum believes that integrating sustainable development principles into their core business strategy helps them to create and add value to their business by enabling them to acquire appropriate contracts and operate efficiently while providing superior value to their customers.

Sustainable construction with Novum Structures

| T | (01379) 640040 |

|---|---|

| F | (01379) 640311 |

| E | info@novumstructures.co.uk |

| W | Visit Novum Structures's website |

| 14 Hopper Way, Diss Business Park, Diss, Norfolk, IP22 4GT |

Products by this Company