Structural Frames

Novum Structures

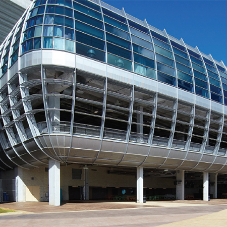

Novum’s six distinctive lightweight structural systems were developed to solve demanding architectural challenges. The systems are fabricated in our ISO-certified factories, architecturally finished, and then shipped compactly.

Comprised of high-grade mild or stainless-steel profiles, Architecturally Exposed Steel (AES/AESS) has a clean technological design aesthetic. It provides nominal interruption of the glass surface for maximum transparency. We specialise in hollow sections (round, square, rectangular, and elliptical), but we also offer wide flanges, channels, T’s, angles, and plates.

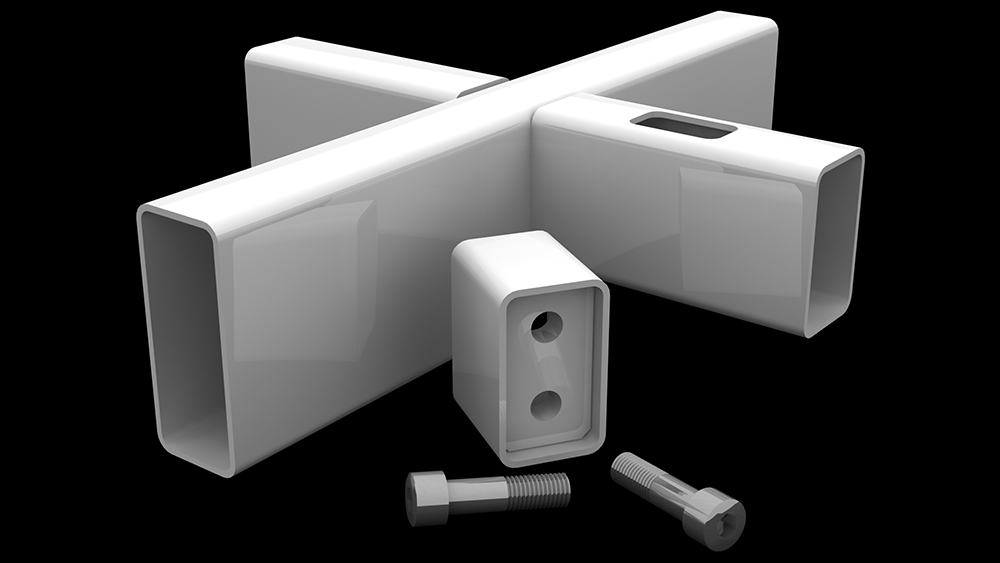

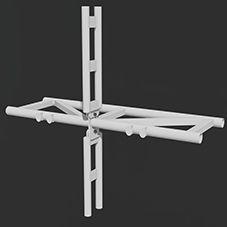

Novum’s Beam to Beam (BB) System is an affordable, yet sophisticated system that is frequently used in facades and canopies, which are planar. Fasteners are typically hidden, or architecturally exposed, and direct cladding is easily accomplished.

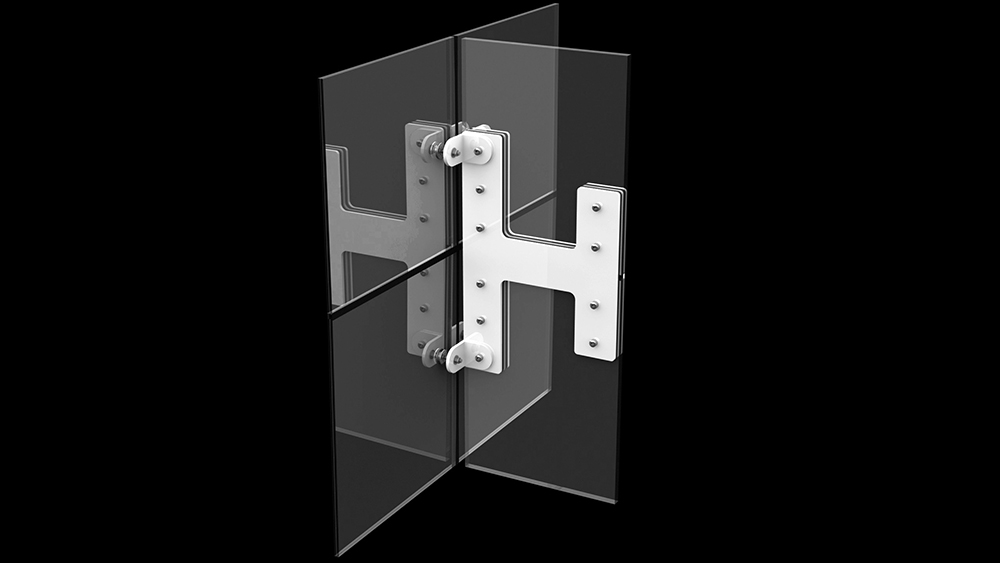

Novum’s Glass to Glass (GG) System extends the traditional role of glass as cladding to structural glazing with stiffening fins used as the primary structure.

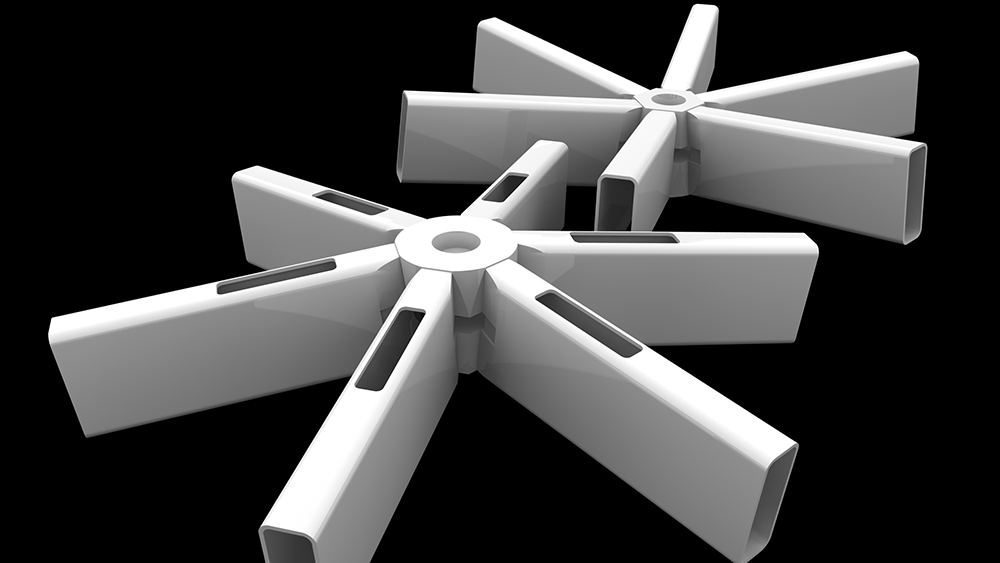

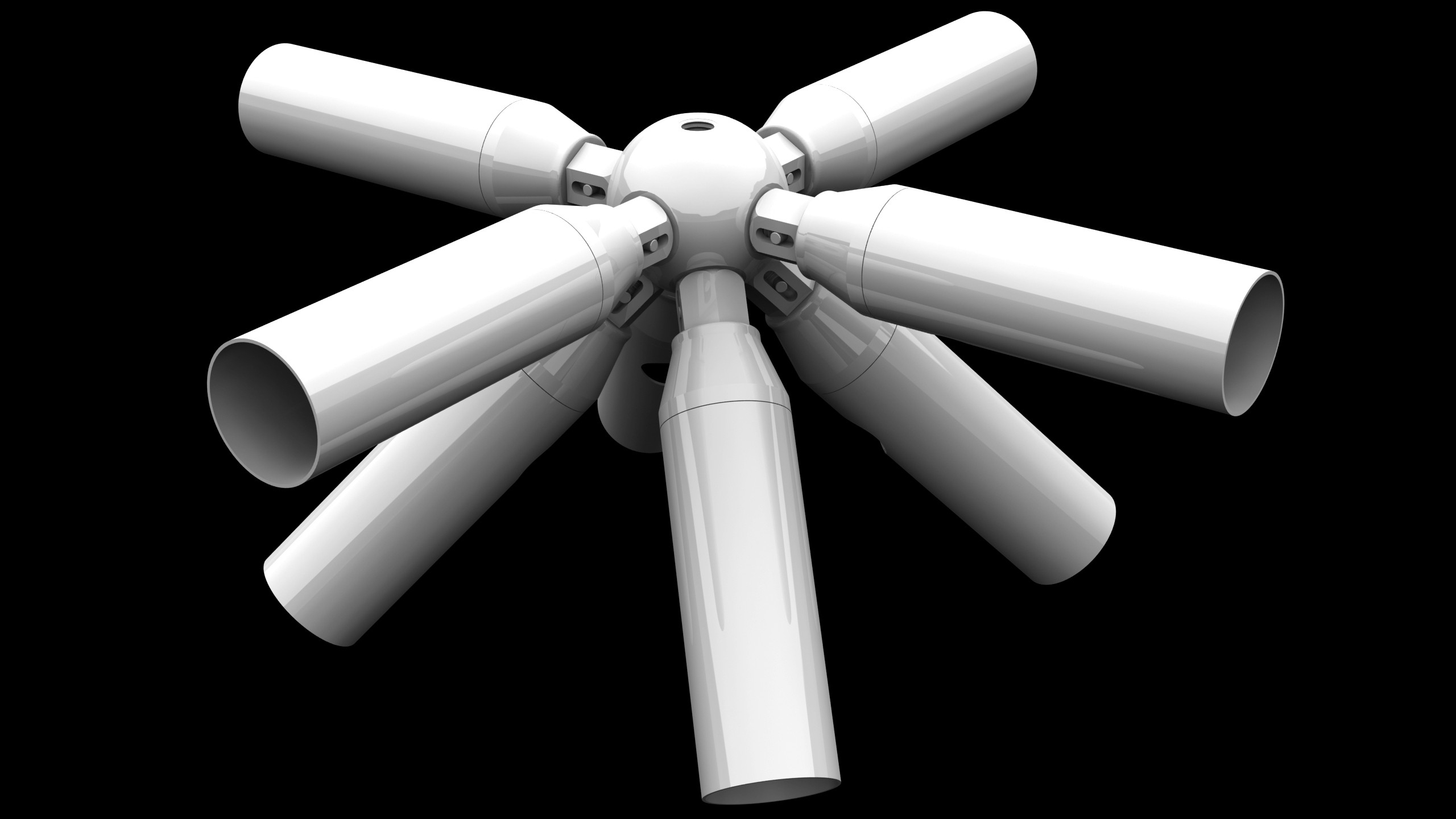

Novum’s Kugel Knoten (KK) System’s ingenious design flexibility enables virtually any geometry. A classic German spaceframe technology that was pioneered by Dr. Mengeringhausen during the 1940s and since has been used on tens of thousands of projects worldwide. Its timeless design of pin-ended lattice work with minimally sized connections and free geometry allows for spans up to 300’ (100m).

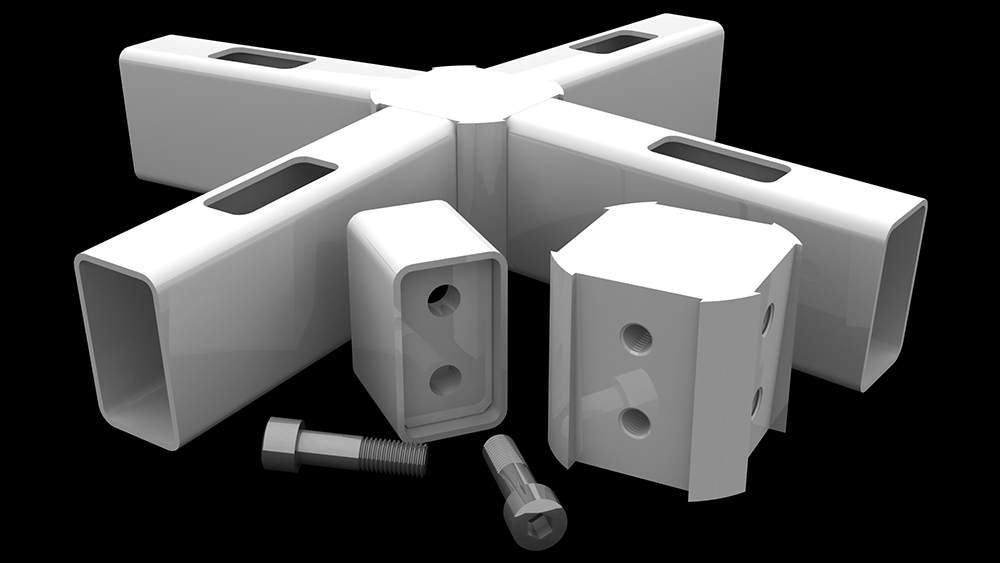

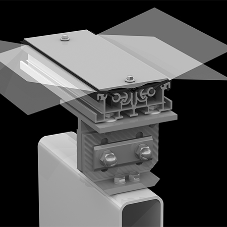

Novum Block Knoten (BK) System is a versatile spaceframe system using machined solid nodes and precise welded beams from hollow sections. BK tubes are used in single-layer and double-layer spaceframe applications and are the preferred choice where geometries are close to orthogonal to keep nodes compact. Single-layer applications use the BK node, and for double-layer grids, the HK node (half-spherical) integrates BK tubes with KK tubes creating bending stiff chord members on stiff spatial grids.

Novum’s Free Form (FF) System is comprised of cylindrical split nodes and tubular beams with cast-end adaptors. The tapered adaptors allow compact node sizes and stepping enables significant vertical angle changes. The split node provides for the economy by its lightness and flexibility for other trades such as lighting and maintenance attachments.